We are a small business located in Gastonia, North Carolina, dedicated to providing top quality industrial hard chrome and electroless nickel plating services tailored to meet the needs of our customers. With over fifty-five years of experience in the plating industry, we take pride in delivering exceptional quality, service, and guaranteed customer satisfaction. Our skilled electroplating team is ready to handle all your plating needs.

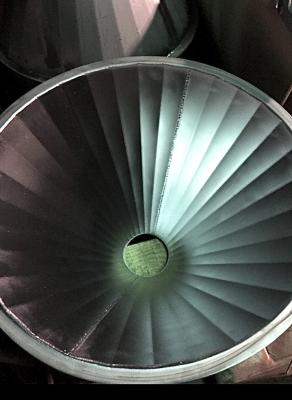

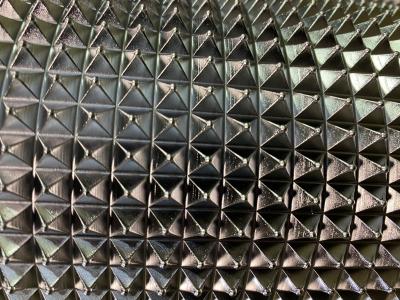

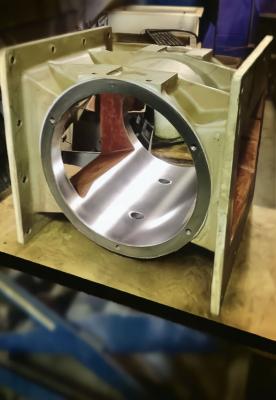

Industrial Hard Chrome Plating Services: This surface will give 2 to 10 times more service life than the original surface eliminating galling and sticking on punches, molds, dies and can make mis-machined and worn parts salvageable. Deposit thickness varies from .000050 to .050 build-up. Selective plating of the I.D. and/or O.D. on one to numerous parts. Finishes include matte, satin, or polished on stainless steel, steel, brass, bronze, cast iron or copper parts.

Electroless Nickel Plating Services: This plated surface has lubricity, conductivity and a uniform deposit to resist rust and corrosion. Deposit thickness varies from .000050/.001. Rack and barrel plating on a single part to production runs on steel, brass, bronze, cast iron and copper parts. Electroless nickel is great for mold bases, parts needing total coverage, and other applications.We provide medium phosphorous electroless nickel plating. An ideal choice for high-volume orders needing fast turnaround.

Other Services: Stripping of previous plating, buffing, deburring, certified plating, baking, polishing and glass-bead blasting services both before and after plating, ensuring a high-quality finish, as well as outside grinding for dimensional accuracy.

Hard chrome and electroless nickel plating improve wear resistance, lower friction, and guard against corrosion, which helps components last longer in tough environments. They enhance performance by reducing galling, restoring worn parts, and offering excellent lubricity for easy mold release, ultimately increasing machine efficiency. The strength and durability of hard chrome lead to reduced maintenance and extended service life. Electroless nickel provides a uniform coating, ensuring consistent thickness on all surfaces, including difficult angles and edges, making it ideal for complex shapes and detailed designs.

Our specialties include the plating of plastic injection and compression molds, cavities, cores, inserts, pins, split-dies, hydraulic cylinders, shafts, military parts, aerospace applications, automotive fuel and brake system components, oil and gas equipment, medical, textile and printing, industrial equipment parts like pumps, gears, shafts and gaskets, mining, heavy machinery equipment, food processing, military, electronics including components like male/female adapters and connectors, as well as pistons, molds, dies, rolls, screws, punches, barrels, guides, mandrels, sleeves, rotors, plates, and other various intricate machined tool parts.

C&R Hard Chrome & Electroless Nickel Service, Inc.

C&R Hard Chrome & Electroless Nickel Service, Inc. has been delivering top quality plating services since 1967, to customers in North Carolina, South Carolina, Tennessee, Virginia, Georgia, and various other states, as well as internationally.