When you own a finishing operation in Wichita, Kansas — as Paragon Services President Brock Elliott does — you are assumed to rely heavily on a certain well-known airplane manufacturer.

Brock Elliott“You can’t help but be Boeing dependent,” says Elliott, whose company was started by his father and a partner in 1979 and offers anodizing, conversion coatings, painting, and some non-destructive examination processes.

Brock Elliott“You can’t help but be Boeing dependent,” says Elliott, whose company was started by his father and a partner in 1979 and offers anodizing, conversion coatings, painting, and some non-destructive examination processes.

In fact, Elliott says in 2020, Paragon had over 40% of its sales tied to Boeing parts, which has many of its aircraft’s components manufactured by tiers in the Wichita area.

But that was the same year that a perfect storm of forces started wreaking havoc on not only the U.S. economy but especially Boeing.

“I’ve been here since 1983, and I never thought I would see the day, but Boeing basically did not build an aircraft for two years,” Elliott says.

Battling the Pandemic and Boeing Issues

The challenges were titanic, as the pandemic was crippling the U.S. economy — and limiting air travel — and Boeing itself was battling issues with its grounded 737 and 787 aircraft because of mechanical issues.

The challenges were titanic, as the pandemic was crippling the U.S. economy — and limiting air travel — and Boeing itself was battling issues with its grounded 737 and 787 aircraft because of mechanical issues.

But Paragon was able to maintain a solid business during that time because of its work with defense contracts and additional work with other aerospace entities that made up the other 60% of its work.

“That percentage is actually good compared to most Wichita businesses,” says Dusty Elliott, Paragon’s Facility Manager — and Brock’s son — who runs most of their operations between two plants that combine to have 37,000 square feet of space.

“We are pretty well diversified,” Dusty says. “But there are a lot of machines shops in the area that are a lot more dependent on the 737 work; a big reason we were able to survive was our military work.”

With 30-foot-long tanks, Paragon offers alkaline cleaning, conversion coatings for both immersion and brush applications, anodizing with boric-sulfuric acid, chemical etching, and deoxidizing.

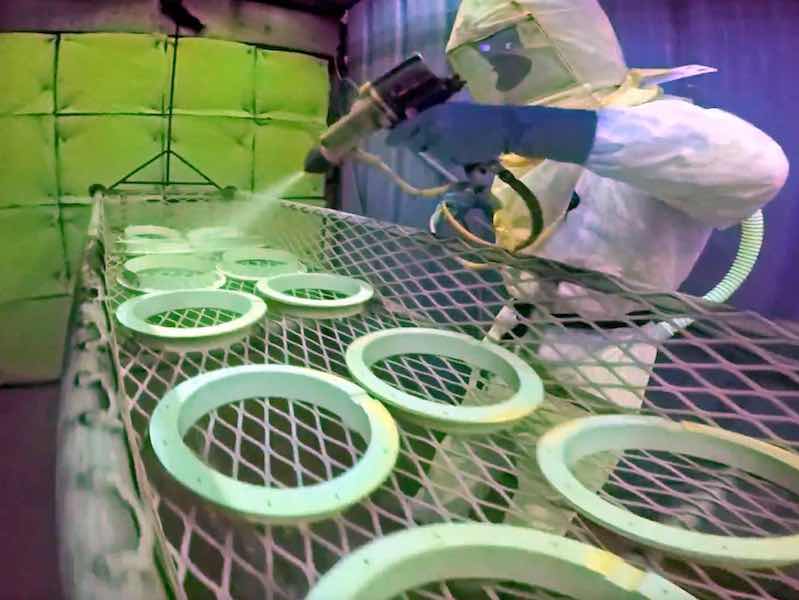

The facility also has multiple spray booths dedicated to primers and topcoats, as well as impermanent coatings such as peelable adcoat. Their hoist and monorail system provides paint personnel the ability to maneuver and coat the most complex parts, and its paint personnel is versatile in applying a wide range of coatings.

Boric Sulfuric Anodizing, Conversion Coatings, and Type II

Paragon Services management team includes, from left, Vice President Robert Rowan, Quality Control Officer Marcy Richardson, President Brock Elliott, and Facilities Manager Dusty Elliott.Marcy Richardson, Paragon’s Quality Control Officer, says that in addition to the boric sulfuric anodizing and Type I color conversions, they have recently added a Type II conversion coating line.

Paragon Services management team includes, from left, Vice President Robert Rowan, Quality Control Officer Marcy Richardson, President Brock Elliott, and Facilities Manager Dusty Elliott.Marcy Richardson, Paragon’s Quality Control Officer, says that in addition to the boric sulfuric anodizing and Type I color conversions, they have recently added a Type II conversion coating line.

Dusty says that because Paragon focuses on only a few specific anodizing and coating processes — instead of the dozens that other shops may offer — they are able to hone their unique processes much easier to get better results.

“I think you’re able to really fine-tune the few processes that you do,” he says. “And I think we’re really good at the few processes that we do.”

The parts that Paragon process range from small clips to large ailerons — the trailing edge of each wing of a fixed-wing aircraft — to large wing skins that go on most Cessna airplanes.

“We have a lot of machine forging and a lot of billets that are machined out to components,” says Robert Rowan, Paragon’s Vice President. “Then we get a lot of sheet metal items like the stringers and similar parts. It’s all extruded and profiled milled, and those can get up to that 30-foot length that we can handle.”

Brock’s father, Larry, founded Paragon NDT & Finishes in 1979 with partner Dail Graham. He says these quiet, unassuming technicians built the business on the basis of “Superior Quality or Nothing.” Brock says they began the business in a small stone house on West Street in Wichita “without even a paper clip.”

Capability to Finish 30-Foot Parts

Paragon offers alkaline cleaning, conversion coatings for both immersion and brush applications, anodizing with boric-sulfuric acid, chemical etching, and deoxidizing.At the time the company was founded, Brock says there were essentially two finishing operations in Wichita, but their tanks were just 10 feet at most.

Paragon offers alkaline cleaning, conversion coatings for both immersion and brush applications, anodizing with boric-sulfuric acid, chemical etching, and deoxidizing.At the time the company was founded, Brock says there were essentially two finishing operations in Wichita, but their tanks were just 10 feet at most.

“All they really did was small parts,” he says. “For all of the larger parts that go on aircraft, anybody in Wichita that was manufacturing these had to ship those parts out of town to be processed.”

Graham was a metallurgist at Cessna at the time, and Larry Elliott was an expert on NDT at a casting foundry in Wichita. The two decided to start their own company specializing in larger parts, as well as NDT services.

In 1980, Paragon opened a new 24,000- square-foot plant equipped with the latest inspection and processing equipment, including an overhead monorail system allowing for ease in moving parts through the various processes.

Paragon was soon selected by Lear Jet to write its NDT inspection manual, which was distributed around the globe by manufacturers of its components, and in 1985 debuted its own mobile lab designed to facilitate the on-site needs of several technicians. It contained all of the equipment necessary for on-site inspections, including x-ray machines and a dark room with a high-volume automated film processor.

Earning Nadcap and Other Certifications

Paragon Services opened a second facility in 2016 and has a combined 37,000 square feet and over 75 employees.In 2002, Paragon Services received its first Nadcap certifications for NDT and for chemical processing as it delved deeper into processing parts for aerospace components. The company later expanded its conversion coating capabilities to include Alodine 600, which provided Paragon with two types of chem-film coatings in addition to its anodize process.

Paragon Services opened a second facility in 2016 and has a combined 37,000 square feet and over 75 employees.In 2002, Paragon Services received its first Nadcap certifications for NDT and for chemical processing as it delved deeper into processing parts for aerospace components. The company later expanded its conversion coating capabilities to include Alodine 600, which provided Paragon with two types of chem-film coatings in addition to its anodize process.

That growth continued and forced Paragon Services to open a second facility in 2016 as a way to obtain a quicker turn-around time and increased volume capabilities. Currently, the company has a combined 37,000 square feet and over 75 employees.

Richardson says when they have their Nadcap audits, the auditors hone in on all of their processes because they don’t have as many others as other finishers.

“It is ‘thorough audit,’” she says. “We not only have the Nadcap audits, but we have all of our process surveillance audits that come in from Lockheed and Bombardier, all the others. I’ll usually have at least a dozen or more each year on top of the Nadcaps.”

Brock says one of the ways that Paragon is unique is that, because of the various audits and performance reviews from its many customers, they have decided to take the most stringent criteria and demands and adhere to that level in all of its operations and processes.

“Instead of us operating differently to 30 chem-film specs for each one of these aircraft companies that we do, what we’ve always done is we take the most stringent criteria, and we incorporate that into our operating procedure,” he says.

Demanding Quality Control Standards

While it guarantees that Paragon will meet all of the different specifications asked of it by any of its customers, it is also very demanding on its staff and quality teams.

While it guarantees that Paragon will meet all of the different specifications asked of it by any of its customers, it is also very demanding on its staff and quality teams.

“But it’s easy on an audit,” Brock says. “They come in and look at our procedures, and it doesn’t take them very long to know that we’re tighter than most specifications that we deal with. So really, we only have one chem-film procedure, but it makes it easier on us.”

Richardson says it also makes it easier for them to train people when they bring them on board.

“Instead of being trained with a whole bunch of different variables, they have one set standard that they are to follow,” she says. “And it helps make internal audits a little bit easier. When I’m going over the procedures, making sure that there’s compliance, it’s easier to keep those parameters in control instead of changing those parameters or changing a solution. You can’t really take a solution and just change the whole way you control it on; you need consistency.”

Of course, while the audits run more smoothly — and customers are getting the absolute best service quality that Paragon offers — there are some drawbacks.

“It’s a double-edged sword, too,” Dusty says. “At the same time, Marcy is constantly fighting OEMs and engineers for deviations. Most companies will just say, ‘Yeah, we’re just going to do it that way.’ But for others, whether or not they do is up for debate.”

Further Diversifying its Operations

In the coming years — and especially with Brock looking forward to turning over more of the company operations to his son — Paragon is looking to even further diversify its operations to help it survive and thrive in future economic conditions.

In the coming years — and especially with Brock looking forward to turning over more of the company operations to his son — Paragon is looking to even further diversify its operations to help it survive and thrive in future economic conditions.

“I’ve got a lot of ideas for things I want to do, but it’s just down the line,” Dusty says. “We would really like to clean titanium, and after going through that pandemic, I feel like there is a need for diversification.”

Dusty says that he and Richardson have also explored looking into doing work with Airbus, which is a Boeing competitor and utilizes a tartaric sulphuric acid (TSA) anodizing process. The European company has engineering and manufacturing operations in Mobile, Alabama, where it assembles A319, A320, and A321 aircraft, producing 60 of them annually.

“Marcy and I someday would like to dive into the Airbus world and see the tartaric anodize, the Type II, and the pre-cleans in those situations,” he says.