The U.S. Department of Energy has awarded researchers a $1.2 million grant to find a way to cure powder coatings at lower temperatures.

Lawrence Technological University in Michigan and partners IPG Photonics, PPG Industries, and Whirlpool Corporation “aim to validate and fully pilot a lower-energy, laser-based powder coat curing technology for industrial coatings applications to replace existing, inefficient natural gas curing ovens.”

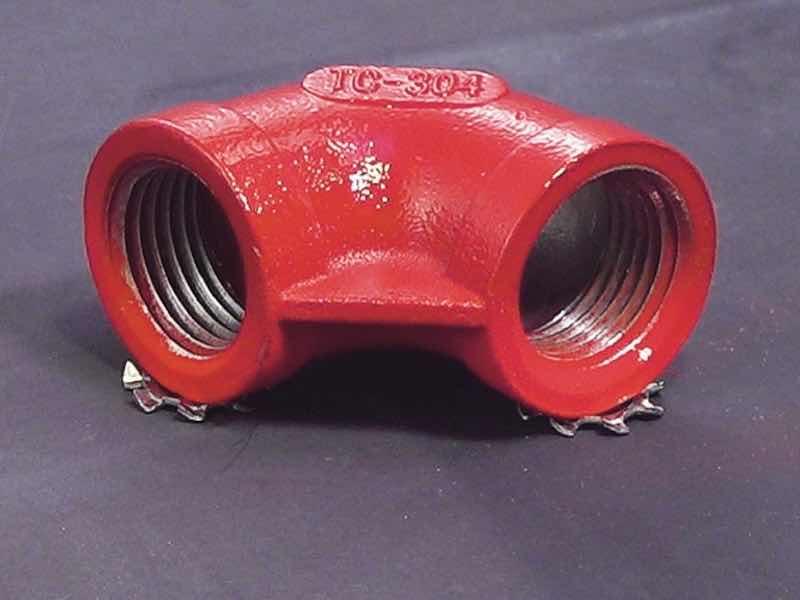

A 3D part that has been laser cured.According to the DoE, the research team “would advance laser-based curing technology for lower temperature coating systems (<250°C) such as powder paint systems as well as higher temperature systems (>400°C) targeting porcelain enamel and other specialty coating applications.”

A 3D part that has been laser cured.According to the DoE, the research team “would advance laser-based curing technology for lower temperature coating systems (<250°C) such as powder paint systems as well as higher temperature systems (>400°C) targeting porcelain enamel and other specialty coating applications.”

“In addition to improving energy efficiency and reducing on-site GHG emissions, the technology has the potential for improved curing cycle times and reduced cooling requirements, which would reduce the physical footprint of the curing process,” the DoE says. “The team would disseminate project results to various industry and stakeholder communities to maximize potential impacts.”

The grant is part of the DoE’s Electrification of Industrial Heat subsector of its partnership with the Electrified Processes for Industry without Carbon (EPIXC) Institute. With more than $43 million in selected projects to support the development of transformational technologies essential for reducing energy use and greenhouse gas emissions across industrial subsectors, 16 projects were selected as part of a $38 million funding opportunity on cross-sector technologies, and five projects selected in partnership with the EPIXC.

Others receiving grants in the Electrification of the Industrial Heat sector were:

- Ames National Laboratory (Iowa): Developing a solid-state elastocaloric heat pump for distillation applications, aiming for 40-80% carbon intensity reduction. ($2.6 million)

- Worcester Polytechnic Institute (Massachusetts): Working on laser-based process heating electrification for food and paper applications, targeting 20-40% energy efficiency gains. ($2.75 million)

- Blue Mountain Energy (Nevada): Building a high-lift air-source heat pump using advanced compression cycles and low-GWP refrigerants. ($3 million)

- Rondo Energy, Inc. (California): Creating an advanced heat battery for high-temperature industrial heating, aiming for 25-40% increased storage capacity. ($2.99 million)

IPG Photonics has already produced equipment that uses laser heating to cure powder coat applications. According to the company, laser curing can occur in as little as one minute and reduces curing time by a factor of 10. The system is 55% more energy efficient and is maintenance-free for up to seven years.