Parts that are manufactured using lubricants or machine coolants in the processes are generally cleaned later with an aqueous chemical agent to remove these contaminants from the parts prior to the next process.

Joe McChesneyThis cleaning action creates an industrial waste stream, which significantly affect the bottom line for operational cost control. This includes raw material purchases of the cleaning agent, periodic bath replacement, actual disposal of contaminated bath with entrained soils, down time/shop labor/clerical work, and additional miscellaneous items that quickly add to overall operational cost.

Joe McChesneyThis cleaning action creates an industrial waste stream, which significantly affect the bottom line for operational cost control. This includes raw material purchases of the cleaning agent, periodic bath replacement, actual disposal of contaminated bath with entrained soils, down time/shop labor/clerical work, and additional miscellaneous items that quickly add to overall operational cost.

I firmly believe it is impossible to eliminate all waste streams that are generated by a cleaning process. The “smart money move” is to identify and reduce defined waste streams as much as possible in a cost-effective manner for financial benefits.

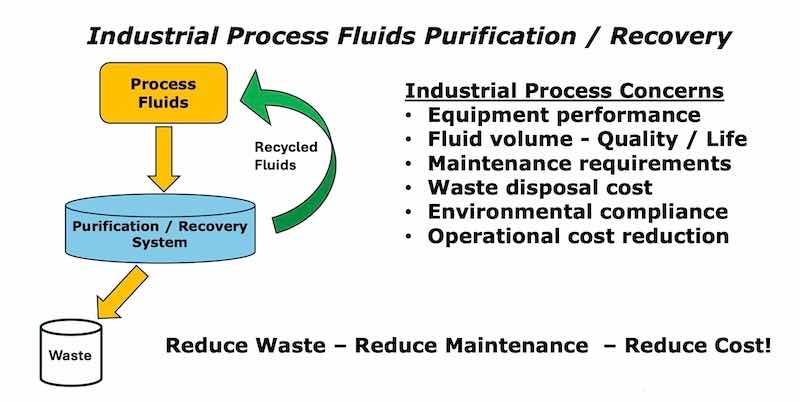

Industrial process recycling is critical to lower operational cost through re-use of materials while reducing costly disposal of waste streams.

Waste Minimization / Process Optimization Challenges

Manufacturers today must address all operational cost factors to stay competitive and meet budgetary goals.

Modifications in parts cleaning processes generally affect the required performance results and cleanliness levels. Throw in typical EH&S concerns for the chemistry applied (including personnel safety, restrictions on air emissions, waste discharge/disposal compliance, etc.) and you soon find that the manufacturing performance and operational cost is directly related to all these items.

Industrial Process Fluids used in most manufacturing processes (machining, stamping, forming, metalworking, parts washing, etc.) are consumable items. Today’s operational costs continue to increase due to escalation of:

- Replacement materials prices

- Labor

- Waste Disposal

- Other factors that contribute to the overall operational cost

Where to Start?

- Plan to conduct audit on all waste streams pertaining to a specific process.

- Identify what streams are being generated (type, volume, and frequency).

- Cost assigned to process / dispose of the waste (ensure all factors are accounted).

- This data will provide approximate baseline cost for review.

- Consult personnel (operators, maintenance, anyone who deals with waste disposal) to obtain their input or ideas on how to effectively improve performance.

- Investigate possible waste source reduction through process optimization or efficiency improvement using new technology.

- The data obtained will help identify any future actions to implement recycling/reuse of existing materials or consideration of a change to the process for cost improvement.

Investment vs Return

- Process optimization can yield cost savings if the current process (equipment or chemistry) is not providing optimum performance. Process review is best accomplished by a person that has knowledge and/or experience with the specific application.

- The type of equipment being used to conduct the cleaning process must be reviewed to ensure proper application and efficient performance to meet production requirements.

- Likewise, the cleaning agent should be selected to match the substrates compatibility being processed as well as removal efficiency of the contaminants on the parts.

- Parts cleaning chemistry must also work well with new or existing equipment design to provide the desired performance.Oil separation and recovery are very important when evaluating chemical options.

- Consider equipment or chemistry that offers efficient performance, reduced environmental impact, and long-term sustainability.

- The investment to enhance your process will return cost savings in many ways for the future.

Aqueous cleaning chemistries fall into one of two general types, (1) Oil Splitting, and (2) Oil Emulsifying. Oil-Splitting (Non-Emulsifying) cleaning chemistries allow for efficient separation and removal.

Benefits of oil splitters include longer bath life, cleaner baths and cleaner parts, lower cost of operation, and less fluid waste.

Auxiliary Options for Recycle Applications

- Skimmers and Coalescers: removal of non-emulsified oils and/or coolants that can be separated from the cleaning fluids.

- Oils and Hydraulic Fluids Filtration: removing solid contaminants /particulates / moisture to meet application specs. Various filtration types/levels are offered.

- Waste Water Treatment Systems: allows removal of emulsified oils, heavy metals, and suspended solids from various wastewater streams.

- Ozone Treatment: bacteria control/coolant de-odorizing

The Smart Money Move

- Purify / Recover Fluids - Not throwing away chemistry.

- Concentration of soils – reduced waste stream.

- Extended bath life – reduced service intervals.

- Reduced waste stream disposal – cost reduction.

- Rapid ROI yielding long-term savings and efficacy.

- Lowers total operational cost.

Joe McChesney and Chuck Sexton are the principals behind Mid-America Cleaning Technologies in LaGrange, Kentucky. MACT can provide a knowledgeable process expert who can deliver technical insight for the best solution to match your cleaning requirements with the focus on a more environmentally safe and cost-effective process. Visit www.mactky.com or email info@mactky.com.