When you speak about producing aluminum, nothing gets bigger than 163,000 square feet of space to produce it in.

That is how much space ALMAG Aluminum is rejuvenating into their newest extrusion and anodizing facility in Pennsauken Township, New Jersey. The Canada-based company is giving new life to an older building with a somewhat checkered past and hoping to better serve its North American customers faster.

“ALMAG is now in a stronger position to support current and prospective customers throughout North America,” says Joe Jackman, the president of ALMAG, which is based in Ontario, Canada.

The facility is part of nearly 560,000 square feet of manufacturing that became available in 2021 when the previous owners — also an aluminum extrusion company — went bankrupt. Western Extrusions is taking one part of the facility, and ALMAG is taking another portion, while other areas of the facility will support the growing logistics industry in Pennsauken.

Fully Automated Anodizing Line with 30-Foot Lengths

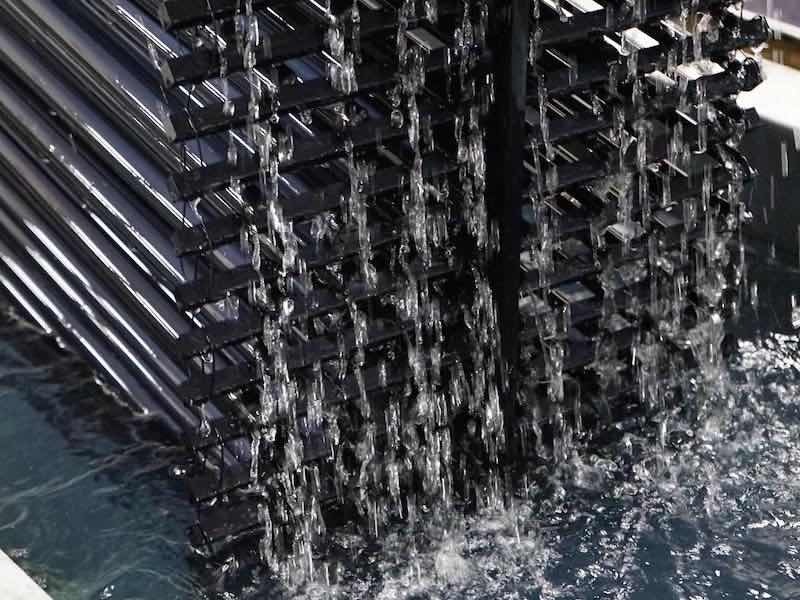

Joe JackmanIn leasing the facility in late 2022, ALMAG acquired two extrusion presses —at seven and nine inches — along with a fully automated anodizing line, which has the capability of anodizing lengths up to 30 feet. In addition, ALMAG also invested in a variety of fabrication equipment, including CNC machines, punch presses, and saws.

Joe JackmanIn leasing the facility in late 2022, ALMAG acquired two extrusion presses —at seven and nine inches — along with a fully automated anodizing line, which has the capability of anodizing lengths up to 30 feet. In addition, ALMAG also invested in a variety of fabrication equipment, including CNC machines, punch presses, and saws.

“The newly acquired equipment is almost a mirror image of what we have in Ontario,” Jackman says. “The New Jersey facility is an extension of our existing operations and will produce the same type of complex, specialized profiles that we are already focused on. This development is a win-win for ALMAG and the local economy.”

Rob Nelson, Executive Vice President at ALMAG, says one of the first things their team had to do was spruce up and refurbish the anodizing operations.

The facility is part of nearly 560,000 square feet of manufacturing that became available in 2021.“There was a lot of work to complete when we first arrived,” he says. “It took us about four months, and we had to clean, pressure wash, and pretty much scrape everything. But for the most part, we haven’t had to make any significant investments yet.”

The facility is part of nearly 560,000 square feet of manufacturing that became available in 2021.“There was a lot of work to complete when we first arrived,” he says. “It took us about four months, and we had to clean, pressure wash, and pretty much scrape everything. But for the most part, we haven’t had to make any significant investments yet.”

ALMAG Aluminum is one of the largest aluminum extrusion and anodizing operations in North America. Its history began in 1953 when Edward Peacock founded ALMAG Aluminum and Magnesium Ltd., manufacturing decorative door grilles. ALMAG’s first aluminum extrusion press started production in 1959. The company has more than 350,000 square feet spread across four buildings in Brampton, Ontario.

Locations in Alabama and Now New Jersey

The New Jersey location isn’t ALMAG’s first venture into the U.S.; in 2011, they purchased a 30,000-square-foot warehouse and manufacturing facility in Ardmore, Alabama, to support the growing demand from customers. In 2020, ALMAG purchased assets from an extrusion company and now has the capability to extrude, fabricate, and warehouse out of its Florence, Alabama, location.

ALMAG has found success specializing in several major manufacturing sectors:

- Medical and healthcare.

- Lighting systems.

- Office systems and furniture.

- Store fixtures and signage

- Solar energy.

The New Jersey location has just one anodizing line, but it should be plenty to do the work for now.

The New Jersey location has just one anodizing line, but it should be plenty to do the work for now.

“It’s a large, fully automated line with 30-foot tanks,” Nelson says.

The facility was once owned by Aluminum Shapes, an extrusion and anodizing manufacturer that had, at one point, over 3,000 employees at the New Jersey plant. In 2021, the company filed for Chapter 11 bankruptcy proceedings that resulted in an auction for its assets in 2022.

The bankruptcy at the same time that the owner of Aluminum Shapes — Zhongtian Liu of Liaoyang, China-based China Zhongwang — was charged in U.S. federal court in a scheme to avoid tariffs on aluminum imports.

According to evidence presented at the nine-day trial, Zhongwang Holdings — Asia’s largest manufacturer of aluminum extrusions —Liu, the company’s former president and chairman, several individual defendants, and the corporate defendants lied to U.S. Customs and Border Protection to avoid paying the United States $1.8 billion in anti-dumping and countervailing duties (AD/CVD) that were imposed in 2011 on certain types of extruded aluminum imported into the United States from China.

The U.S. Department of Justice says the aluminum sold to U.S.-based companies controlled by Liu was simply aluminum extrusions that were spot-welded together to make them appear to be functional pallets. In fact, the DOJ says there were no customers for the 2.2 million pallets imported by the Liu-controlled companies between 2011 and 2014, and no pallets were ever sold.

Ability to Powder Coat, Ecoat, and Anodize

ALMAG’s goal now is to breathe new life into the New Jersey facility and better serve its customers, and having more extrusion and anodizing capacity will do that, Nelson says.

ALMAG’s goal now is to breathe new life into the New Jersey facility and better serve its customers, and having more extrusion and anodizing capacity will do that, Nelson says.

“We want to be in control of the lead time,” he says. “ALMAG is a one-stop shop aluminum extrusion company.”

ALMAG first added in-house finishing and coating to its extrusion and manufacturing portfolio in 2009 when it purchased Byers Bush Powder Coating in Mississauga, ON, to offer powder coating to customers who needed a final finish.

In 2017, ALMAG bought a previous anodizing supplier, Dependable Anodizing, to bring that process in-house as well. Dependable had been servicing ALMAG for over 40 years from their operations in Markham, ON.

Rob NelsonDependable Anodizing has been operating since 1974, specializing in the architectural, industrial, and commercial markets and offering caustic and sulphuric acid anodizing in both conventional and two-stage electrolytic colors, as well as clear anodizing in caustic and acid etch finish.

Rob NelsonDependable Anodizing has been operating since 1974, specializing in the architectural, industrial, and commercial markets and offering caustic and sulphuric acid anodizing in both conventional and two-stage electrolytic colors, as well as clear anodizing in caustic and acid etch finish.

In 2022, ALMAG acquired Trinity E-Coaters Brampton, ON, which was started in 1966 and had a 40,000-square-foot facility, giving them even more options to service their coatings with specific coating needs.

“Trinity is fairly automotive intensive, so we are in the process now of trying to diversify them a little bit,” Nelson says. “Ecoating is expanding into other industries now, so we have picked up some customers in the office furniture industry now, and we hope to grow into more.”

Buying Facilities Rather than Starting New

About 10% of what ALMAG produces needs a powder coat, but Nelson says nearly everything they produce will need a finish, which is why having anodizing, ecoat, and powder coating available is a large advantage. Starting their own finishing process lines — instead of buying existing operations — seemed prohibitive.

About 10% of what ALMAG produces needs a powder coat, but Nelson says nearly everything they produce will need a finish, which is why having anodizing, ecoat, and powder coating available is a large advantage. Starting their own finishing process lines — instead of buying existing operations — seemed prohibitive.

“There are a lot of environmental concerns these days, and I think from a permitting standpoint it would be a challenge in the future to just start our own,” he says. “So when we had the chance to acquire a few of these facilities that we think that we’ll need, that way there we ensure our supply chain and our customers are protected.”

Nelson adds that with the New Jersey location, they originally were looking at purchasing the equipment to move to another location but ended up signing a lease to run operations out of that facility. He says it made sense to be located near where a lot of their U.S. customers are.

“The number one thing that we offer our customers is we want to offer the shortest lead times in the industry,” Nelson says. “All of our organizations typically are 10 business days or less. That’s the reason why we bought New Jersey because our lead times were not 10 days or less. And we needed more capacity for our growth.”

Huge Customer Demand Driving Nearly All Operations

ALMAG has seen a huge demand from its customers, which is driving nearly all of its operations as it maintains customer service and quality expectations.

ALMAG has seen a huge demand from its customers, which is driving nearly all of its operations as it maintains customer service and quality expectations.

“It was one of the key contributors to us making this decision to buy those presses and anodizing line in New Jersey,” Nelson says. “There are times when our company is growing quickly.”

While Almag’s operation in Markham has over 100 employees working in the anodizing department, they have only a handful so far in New Jersey as they begin running prototypes through the system.

But when the facility goes full production, the New Jersey plant will be humming as new orders come in for ALMAG.

“We’ll have the ability to run up to three shifts down there,” Nelson says. “That would mean we’re probably looking at about 25 people total working at that plant in the anodizing department.”

The New Jersey location has about 25 million pounds of extrusion capacity per year. Nelson says the anodizing line will have the capacity to support extrusion, which is plenty for what they will need, and they will be looking for additional business.

“We do have a lot of opportunities for growth with all the processes we have,” he says. “We’re running one shift on the ecoat line right now, and our power coat line only runs two shifts. We’ve got lots of capacity right now, which is where we would like to be. That way, when we need to ramp up and add resources to support our customers, we can do it fairly quickly and efficiently.”

Visit https://almag.com