Jacqueline Cook, Lab Chemist for Reliant Aluminum Products, provides this presentation on Non-Nickel Seal Alternatives for Dyed Aluminum.

Please click the video above to watch the presentation.

Early in the history of anodized aluminum, nickel seals displaced boiling water for several reasons:

- Less dye bleed.

- Improved seal quality.

- Longer bath life.

- Improved light fastness.

With today’s environmental pressures to eliminate nickel from the process there is an interest in revisiting the use of boiling water and other Ni-free alternatives to determine best available options.

Dye bleeding is affected by the type and the activity of the dye as well as the type and quality of the seal. Older (used) dyes tend to bleed far more than those that are newly made up and bleeding of any dye can be significantly improved by increasing the dye activity through the use of a buffer and/or high application temperature. For the purposes of the tests reported herein, a customer supplied 1-year old Sanodal Deep Black HBL dye was used under standard conditions of 140F and 15 minutes. The activity of this dye was 80% relative to a new bath of equal composition and therefore bled notably more. Type II class 2 coatings of 0.7 mil thickness were prepared and sealed in a variety of newly made seals.

Longer Immersion Times or Higher Seal Temperatures

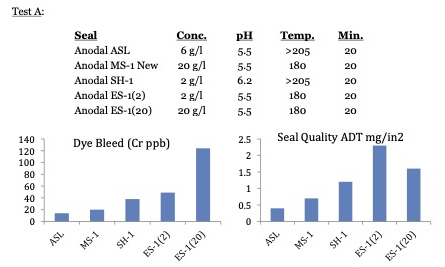

The nickel seals (Anodal ASL and Anodal MS-1 New) outperformed the Ni-free seals with respect to bleeding and seal quality. Anodal SH-1 was the best Ni-free alternative, but this hot water seal has its shortcomings in that it must be dumped frequently and run at a very high temperature. Next best for bleed performance was low concentration Anodal ES-1 (2), but the quality of seal was inferior. To compensate, longer immersion times or higher seal temperatures would be required. The worst seal for bleeding was standard concentration Anodal ES-1(20), although this long-lasting seal did perform reasonably well with respect to seal quality.

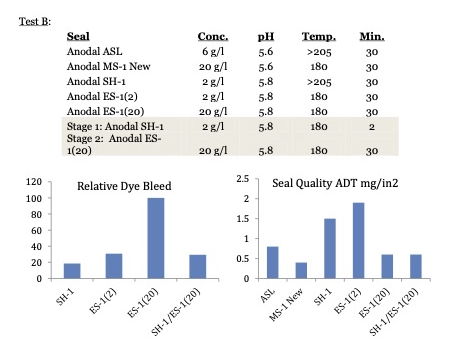

These results confirm the main findings of Test A but they also show that a standard concentration Anodal ES-1 can be used with 70% less bleed if it is run as the second step of a 2-step seal, the first step being a short hot water (180F) dip. Doing so, results in good bleed performance without seal quality deterioration. Such a pre-seal could well be imagined as the second rinse following the dye step. The results also show the improvement to seal quality that duration and pH has on Anodal ES-1(20), essentially bringing them in line with the nickel seals.

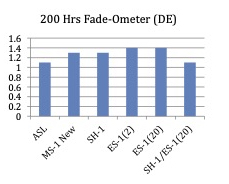

MIL-A-8625F stipulates that upon exposure to Xenon arc fade-Ometer for 200 hours that the color loss is no greater than 3 units as expressed as DE CIE Lab. The chart shown at right indicates that all panels easily passed this requirement and it also shows that for a used Sanodal Deep Black HBL dyed panel the differences in fastness properties due to seal chemistry are not as significant as one might expect.

MIL-A-8625F stipulates that upon exposure to Xenon arc fade-Ometer for 200 hours that the color loss is no greater than 3 units as expressed as DE CIE Lab. The chart shown at right indicates that all panels easily passed this requirement and it also shows that for a used Sanodal Deep Black HBL dyed panel the differences in fastness properties due to seal chemistry are not as significant as one might expect.

In conclusion, these results suggest that to achieve quality results comparable to nickel, the preferred method of nickel free sealing black anodized aluminum is by either:

- Using a boiling water seal with smut control additive.

- Using a >180° low concentration (2 g/l) Anodal ES-1 for an extended period of time.

- Using a mid-temperature 2-stage seal whereby the pre-seal is 180° water with Anodal SH-1 (dumped regularly) and the second seal is 180° Anodal ES-1 at 2% concentration. This would allow high quality seal results in a relatively short period of time at medium temperature.

Appendix 1 Test Details

AA5005 panels were anodized together for 35 minutes at 70F to form a coating that measured 0.7 mil in thickness. These panels were well rinsed and dyed in the customer supplied Sanodal Deep Black HBL dye bath at 140F for 15 minutes. The dyed panels were rinsed under running water and sealed in individual seal baths.

Each of the dyed panels measured 4.5in x 37 in for a total dyed surface area of 6.8in2. Sealing was carried out in 50 ml test tubes maintained at temperature using a thermally controlled hot water bath. Seal quality was determined using ASTM B680 procedure and bleed was measured:

Test A: By determining the chrome content of the seal baths using ICP AES.

Test B: By measuring the depth of color of the (originally clear) Ni-free seal solution using a spectrophotometer and the worst performer (Anodal ES-1(20)) as the comparative standard.

Light fastness was determined by exposing sealed panels to 200 hr Fade-Ometer per ASTM G26 and measuring the DE color loss with a spectrophotometer.