Most of us, through experience, can relate to the strong link between effective filtration and quality metal finishing of parts.

Stephen Rudy CEFOne would be hard-pressed not to see some form of filtration in a plating line. By walking the line backward, how many cleaner tanks have you seen being filtered? Do you think it is a good idea? Is there any real benefit?

Stephen Rudy CEFOne would be hard-pressed not to see some form of filtration in a plating line. By walking the line backward, how many cleaner tanks have you seen being filtered? Do you think it is a good idea? Is there any real benefit?

From practical experience using filtration equipment and formulating specific cleaners, it has been shown that filtering these baths is a good decision. Let us consider some reasons for filtering cleaners and some available methods.

Is It Clean or Dirty?

Obviously, the ideal condition for any cleaner is the freshly prepared working solution just before immersion of any parts. After the initial dunk of parts, the solution becomes soiled—as should any good soak cleaner behave. As production use proceeds, the bath loads up with contaminants typically consisting of oils, grease, and fine particles. Perhaps you have noticed the telltale signs: solution turns either a dark or tea brown, milky color, oils tend to separate and float (especially as the cleaner cools), grease rings form on the walls of the tank, sludge, and particles build up on the bottom of the tank. Just how soiled does the cleaner become before it starts working against you? Why not try a couple of quick tests that might tip off trouble before it occurs?

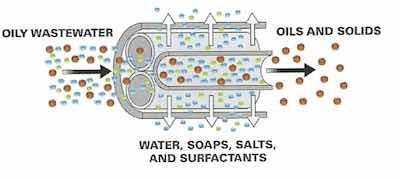

Ultrafiltration and how it works. Credit: advanceddeburring.com

Ultrafiltration and how it works. Credit: advanceddeburring.com

- Specific Gravity. Measure the cleaner bath’s specific gravity when first made up (no parts having been immersed). On a scheduled basis, measure and record the specific gravity as the bath ages. This value will increase. During the soak cleaner’s service life, maintain a cleaner concentration within 90 to 100% of the initial makeup. There will be a point at which the specific gravity data coincides with a drop in quality cleaning. The specific gravity will have increased to a point that indicates how much oil, grease, and particles have built up in the bath, thereby reducing the soak cleaner’s efficiency. When this occurs, the analyzed concentration of the cleaner may have been compromised by the accumulated oil, grease, and sludge built up. Corrective action may include making additions to the cleaner concentrate, cutting the bath and replenishing, or dumping and replacing it with a new make-up.

- Performance Test. Immerse a clean panel (e.g., Steel hull cell panel) in the cleaner bath for the same time and temperature as the parts. Rinse in cold running water for 60 seconds and examine for water breaks. If no water breaks, continue. Next, immerse the rinsed panel in dilute acid (5% hydrochloric or sulfuric acid) for 15 seconds, followed by rinsing in cold running water. Examine for water breaks. A positive observation of water breaks at either step would indicate the deposition of soils from the cleaner bath onto the panel. Once again, corrective action may include making additions to the cleaner concentrate, cutting the bath and replenishing, or dumping and replace with new make-up. As a tip, if an addition of 20% make up to the cleaner does not result in the panel to be water break free, better to dump the existing cleaner.

- Oil Displacement. As the bath ages, the concentration of emulsified oily soils becomes more concentrated. Take a 50-milliliter sample of the hot cleaner and, using care, slowly add 50 milliliters of 10% sulfuric acid. Mix the solution well for about 15 minutes. Pour the solution into a clean 100-milliliter graduate cylinder; adjust volume, if necessary, with water to 100 milliliters. Observe as the oils separate. Record the volume and multiply by two to obtain the percent of displaced oils. As with the two previous tests, corrective action may include making additions to the cleaner concentrate, dilute the bath and replenish, or dump and replace with a new makeup.

Confirm Maximum Service Life

A belt skimmer. Credit: Abanaki CorporationThese control examples confirm or predict at what point the cleaner, even with proper maintenance additions and correct operating temperature, will approach its maximum service life. In most instances, adding more cleaner concentrate may restore quality cleaning, but perhaps only for a short time. We have only considered how to determine the extent of cleaner contamination with the same type of corrective action alternatives. In no instance has any consideration been given to removing the contaminants or minimizing their buildup. Can this be done? Yes, quite effectively. By filtering the cleaner, the following realistic benefits are readily obtained:

A belt skimmer. Credit: Abanaki CorporationThese control examples confirm or predict at what point the cleaner, even with proper maintenance additions and correct operating temperature, will approach its maximum service life. In most instances, adding more cleaner concentrate may restore quality cleaning, but perhaps only for a short time. We have only considered how to determine the extent of cleaner contamination with the same type of corrective action alternatives. In no instance has any consideration been given to removing the contaminants or minimizing their buildup. Can this be done? Yes, quite effectively. By filtering the cleaner, the following realistic benefits are readily obtained:

- Extend cleaner bath service life. Less downtime means longer periods of uninterrupted productivity.

- Fewer bath dumps reduce the workload in waste treatment.

- Minimizing contaminants in the cleaner helps to maintain the consistency of the solution and keep it closer to the new makeup.

- Quality cleaning results in satisfactory surface preparation, leading to quality finishing and post-treatment.

- All the above points relate to operating cost savings

The cleaner can be filtered using some different options:

Cartridge Filter. These are enclosed canister types that have a polypropylene center around which similar fiber material is tightly wound. The porosity of the filter medium can range from 100 microns to below 5 microns, based on the specific filtering requirement. Particles are retained in the media pattern. The polypro material absorbs oily solutions. The cleaner is continually pumped through the filter cartridge. It is a relatively simple yet effective system for removing the typical contaminants found in the cleaner. The unit does not take up much floor space. When spent, the end user or supplier can dispose of cartridges, sometimes directly to a certified destruct facility.

Oil Absorbing Filter. This unit consists of an enclosed housing that contains polypropylene baskets containing special oil absorbing plastic type media. The cleaner is pumped through the enclosed system, where the media absorbs oils and grease. The saturated media is replaced as needed.

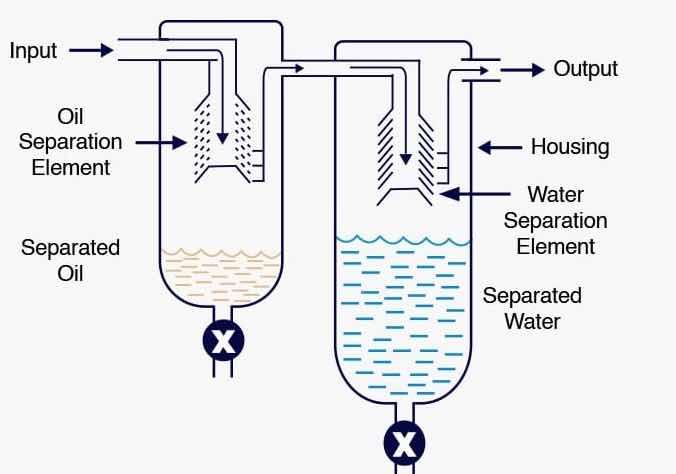

Oily soils removal by Coalesce. Credit: multitexgroup.comBag and Indexing Fabric Filters. The cleaner is pumped through a large filter chamber where oil, grease, and particles are retained. Takes up large floor space. It is a decent filtration system, but not applicable to systems cleaning large volumes of very oily parts.

Oily soils removal by Coalesce. Credit: multitexgroup.comBag and Indexing Fabric Filters. The cleaner is pumped through a large filter chamber where oil, grease, and particles are retained. Takes up large floor space. It is a decent filtration system, but not applicable to systems cleaning large volumes of very oily parts.

Ultrafiltration. This is an interesting technology, using a somewhat permeable membrane system. The aged cleaner is pumped through the (ceramic) membrane tubes. Molecules of sizes larger than water are blocked from passing through and diverted to a discharge. The aqueous cleaner solution passes through and returns to the process tank. Ultrafiltration provides a rapid, very dramatic filtering action. Of the examples given, ultrafiltration is by far the more expensive. A flexible or mobile unit that can be used to treat several cleaner tanks can offset the application of purchase or rental, as required.

Other Equipment. Filtration can be supplemented by the application of mechanical oil removal devices. These units are quite cost effective and can be used in-tank. An overflow weir or side tank can collect cleaner solution, which cools down about 10–20°F below the temperature of the cleaner while oils separate to the top. The oils can be skimmed off using a disk or belt. A coalescer is another oil removing device. It channels the flow of cleaner, separating the aqueous from the oily solution.

Disk skimmer. Credit: zebraskimmers.comAnother Consideration. Assisting in the filtering of cleaners would be helpful to evaluate the type of cleaners to be used. Displacement cleaners, for example, remove and release the oils for quick removal by the filter or separator. Another type of cleaner is what I refer to as the “mini emulsion.” Oils are kept emulsified as long as the cleaner is agitated (such as barrel soak cleaning). When the solution settles in dead zones or in a side tank, oils are released, at operating temperature, for suitable and efficient removal. Another choice is the emulsion cleaner that releases oils by simple cooling (e.g., from 160°F down to 120°F). A chemical additive can also be added to certain cleaner formulations. The mixture of agents selectively emulsifies the oils in favor of the heated cleaner, immediately splitting out in mass with the oils.

Disk skimmer. Credit: zebraskimmers.comAnother Consideration. Assisting in the filtering of cleaners would be helpful to evaluate the type of cleaners to be used. Displacement cleaners, for example, remove and release the oils for quick removal by the filter or separator. Another type of cleaner is what I refer to as the “mini emulsion.” Oils are kept emulsified as long as the cleaner is agitated (such as barrel soak cleaning). When the solution settles in dead zones or in a side tank, oils are released, at operating temperature, for suitable and efficient removal. Another choice is the emulsion cleaner that releases oils by simple cooling (e.g., from 160°F down to 120°F). A chemical additive can also be added to certain cleaner formulations. The mixture of agents selectively emulsifies the oils in favor of the heated cleaner, immediately splitting out in mass with the oils.

Each of the filtering options can also be considered for actual batch treatment of the soak cleaner. For example, two soak cleaners, where one is on line cleaning parts, while the other is undergoing a batch purification.

In-tank filtration and out-of-tank filtration. Credit: Serfilco.comFiltering cleaners offer the metal finisher several benefits. They include quality, economics, productivity, compliance, and safety. The available filtration equipment provides the degree of treatment or sophistication that is preferred. Cleaning is the first step—in fact, the most important step—in a finishing cycle. By effectively filtering the cleaner, the buildup of contaminating soils is kept at a minimum or controlled. Subsequently, rinses and process tanks down the line are kept relatively free of contaminated cleaner solution drag-in.

In-tank filtration and out-of-tank filtration. Credit: Serfilco.comFiltering cleaners offer the metal finisher several benefits. They include quality, economics, productivity, compliance, and safety. The available filtration equipment provides the degree of treatment or sophistication that is preferred. Cleaning is the first step—in fact, the most important step—in a finishing cycle. By effectively filtering the cleaner, the buildup of contaminating soils is kept at a minimum or controlled. Subsequently, rinses and process tanks down the line are kept relatively free of contaminated cleaner solution drag-in.

Filtering cleaners—make a wise choice for the metal finishing operation.

Stephen F. Rudy, CEF, is president of Chem Analytic and has written extensively about the finishing industry. Visit www.chemanalytic.com or call him at 917-604-5001.