Remember the classic 1980s movie, Ferris Bueller’s Day Off?

Barbara and Ed KanegsbergFerris challenged authority. If you want to clean a complicated part or component, you can’t just toss it in the ultrasonic tank using the default settings that an authority has set up for you and told you to never, never change. Challenge authority! Change the settings under controlled non-production conditions. Default settings are a starting point, not an eternal truth of the universe. Ferris made mistakes, so rather than destroying his friend’s dad’s mid-life crisis car or ruining the actual product, use scrap or coupons. If possible, run tests before specifying new equipment. Your potential rewards include a more effective process, a higher quality product, and more customers.

Barbara and Ed KanegsbergFerris challenged authority. If you want to clean a complicated part or component, you can’t just toss it in the ultrasonic tank using the default settings that an authority has set up for you and told you to never, never change. Challenge authority! Change the settings under controlled non-production conditions. Default settings are a starting point, not an eternal truth of the universe. Ferris made mistakes, so rather than destroying his friend’s dad’s mid-life crisis car or ruining the actual product, use scrap or coupons. If possible, run tests before specifying new equipment. Your potential rewards include a more effective process, a higher quality product, and more customers.

Over the years, ultrasonic cleaning systems have become more complex; materials of construction of newer products have evolved; and cleaning agent formulations have become more diverse. In response, we’ve been doing studies of ultrasonic variables with Steve Norris of Plasma Technology Inc. in Torrance, CA. The results indicate that manufacturers can achieve more effective critical cleaning practices by optimizing the combination of cleaning chemistries, time, temperature, frequency, and power. This means varying the default settings.

A Little Technical Background

Ultrasonics uses the power of high-frequency sound to help remove soils from complex parts. It is useful in both aqueous and solvent cleaning processes. When sound passes through a liquid, tears (cavitation) that become vapor-filled “bubbles” are formed during the rarefaction phase. These bubbles implode during compression. One aspect of the cleaning forces associated with ultrasonics comes from these implosions. Cavitation cleaning is not line-of-sight, which makes it valuable for complex-shaped components. In addition, acoustic streaming provides a line-of-sight cleaning force. The higher the frequency, the smaller the bubbles. All other things being equal, this means more gentle cleaning, better removal of tiny particles, and greater influence of the acoustic streaming access. At very high frequencies (usually considered to be about 5000KHZ), the cleaning force is totally from acoustic streaming, and we talk about megasonic cleaning. Megasonics are used in the critical cleaning of flat surfaces because acoustic streaming is line-of-sight. There are many variables to ultrasonic systems, and that means many choices. Some of these variables are listed in Table 1. With so many variables, we may not be optimizing the system.

Change the Settings

Too often, manufacturers select ultrasonic systems and cleaning chemistries based only on the advice of the sales reps. The assertion that “everybody” is using high-frequency ultrasonics doesn’t mean that high frequency is right for your applications, for your customer requirements. The technical rep who sets up the cleaning system may specify the design of the system, the chemistry, temperature, and the power settings. He or she may then say something like “don’t change anything and don’t touch any of these settings.”

Change the settings – at least test different settings using coupons or scrap (not production hardware!). Evaluate the ultrasonic system you are considering; make sure the new system is optimized; test to see if your current system is doing the job.

Ferris Bueller the Scientist

When we suggest the idea of testing ultrasonic variables with the idea of making your own decision about the cleaning process, the initial response can resemble fear, terror, or even a sense of mischief.

In an article in Spraytime magazine (1), we suggested that you are not Ferris Bueller ogling the new family sound system, and the technical reps are not Ferris’s dad. Evaluating a new ultrasonic system, making sure a current system is optimized, and testing to see that your current system is doing the job involves emulating Ferris a little bit, albeit in a more mature, systematic manner.

In the studies with Plasma Technology, Inc., we have looked at water or aqueous-based cleaning agents with ultrasonics. We tested two frequencies, 40KHz and 132 KHz, with sweep, in Crest benchtop ultrasonic tanks(3). We have tested several cleaning agents using “coupons” made of regular-weight aluminum foil (not heavy-duty). Although cavitation meters are available and can give quantifiable results, aluminum foil is inexpensive and readily available. Therefore, observing the orange peel pattern of aluminum foil is still the most commonly used test for ultrasonic effectiveness.

Foil Cavitation

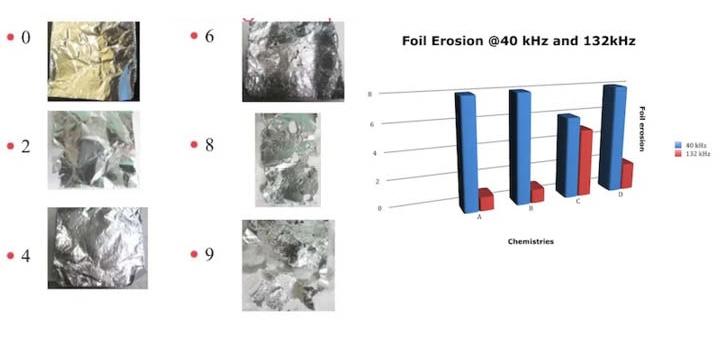

The test material (in this case, aluminum foil) was placed in a glass beaker containing the cleaning agent. The beaker was placed in the ultrasonic tank that was filled with a solution of deionized water and surfactant. Surfactant was added to the water in the ultrasonic tank because conventional wisdom holds that surfactant lowers the surface tension, allowing for more effective cavitation. Results were graded visually. Figure 1shows examples of the grading system for foil (6). Even though your product is probably less fragile than aluminum foil and is therefore less susceptible to ultrasonic erosion, ultrasonic damage can happen. Therefore, observing a level of ‘9’ might be a warning sign that perhaps you are overdoing it with the ultrasonics.

On the other hand, a level of zero or even two could indicate that something is wrong, that ultrasonics are not being effective. For example, the ultrasonic transducers could be malfunctioning. You can’t tell from the noise (unless you have extremely unusual hearing) what you hear is more likely to be secondary harmonics. There could be other sources of low-to-no orange peel pattern associated with the physical properties of the cleaning chemistry or design of the fixtures.

Chemistry and Frequency Comparison

Water and three aqueous chemistries were tested, all using a 10% dilution by volume. The aqueous chemistries tested are indicated in Table 2. Identities are coded because this study is meant to show some variables to consider; it is not an “Iron Chef” contest among cleaning agent formulators.

We tested the impact of water and the three mildly alkaline cleaning chemistries on foil erosion at 40KHz and 132 KHz. Testing was at 55 degrees. C, 85 w/gal (full power), 9 minutes of cavitation. Results are shown in Figure 2. Conventional wisdom (the equivalent of Ferris Bueller’s father) is that higher frequencies produce less ultrasonic damage, and this held true in the current study.

Time, Power

Some people assume that if a short time with ultrasonics is good, a lot more time is better. There are flaws in this reasoning. For one thing, ultrasonic product damage, while controllable, is possible. The longer the time exposure, the more likely you are to see product damage. Unnecessarily long cleaning process times hold up production and use energy. This costs money. Therefore, you may want to test your process using a few different cleaning chemistries in combination with ultrasonics.

In general, most suppliers of ultrasonic equipment claim that almost all of the cleaning action occurs within a short time; some say that 30 seconds of cleaning is plenty; others claim 3 minutes is sufficient.

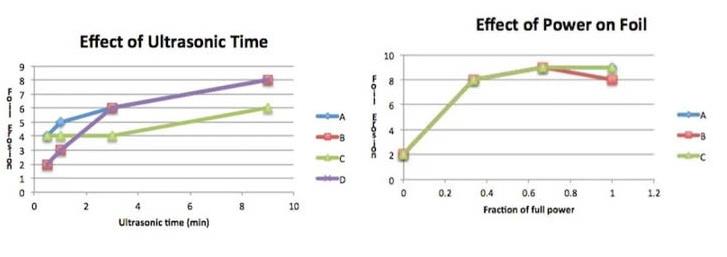

Using water and the same three aqueous cleaning agents, cavitation of foil was evaluated at several times, between 30 seconds and 9 minutes. There was more cavitation with increasing time. However, results were non-linear, and they were chemistry-dependent. (Fig. 3)

Many ultrasonic units come with a power setting that allows you to vary the power from zero to 100%. Using the 40 KHz tank, we varied the power between zero and 100% and cleaned for nine minutes. We looked at water and two aqueous formulations. There was some cavitation even at the setting for zero power. In addition, results were non-linear, and we saw very little impact of chemistry. (Fig. 4)

Don’t Always Emulate Ferris

There are some cases where you want to moderate Ferris’s spirit of adventure. For one thing, you should set the parameters, then set up the process, then cast the variables in stone. In addition, be aware that most ultrasonic systems are not recommended for use with flammable or combustible solvents. If you do need flammable solvents, purchase a system designed for that purpose. Low-flashpoint systems cost more money, but it’s cheaper than rebuilding the facility, and you can’t replace your workers. A bit of practical advice: don’t test ultrasonics by putting foil directly in the tank. Put the foil in a beaker full of cleaning agent, and suspend the beaker in the tank. Otherwise, you could end up contaminating the whole process tank with messy crumpled foil or bits of foil “glitter.” Finally, and this bears repeating: never, never ever clean actual hardware while you are testing the variables. Until you have set up the actual cleaning system, use coupons or scrap parts, and be aware that you may have to run more than one or two tests to get the right conditions. Unexpected and not necessarily desirable results can happen during test development. If we always got it right the first time, there would be no “re” in “research.”

Ongoing Studies

Our investigations of ultrasonic variables continue. We have found that the best cavitation temperature does not necessarily follow results from classic studies – ultrasonic equipment has changed over the last half century. We are also developing techniques to monitor higher frequency ultrasonics, including using a very thin foil, about ½ the thickness of regular weight household foil (5). Stay tuned for further developments.

Table 1: Some Ultrasonic Process Variables

| Variable | Comments |

| Frequency | Higher frequency, smaller bubbles mean less aggressive cleaning |

| Amplitude (loudness) | Higher amplitude means more aggressive cleaning |

| Power density | Power per unit volume |

| Physical & chemical properties of liquid | May have positive or negative effects on cavitation |

| Temperature | Impacts cavitation |

| Time | Impacts soil removal |

| Soil | Viscosity |

| Substrate | Mix of materials, size, shape |

| Substrate fixturing | Materials of construction |

Table 2: Aqueous Chemistries, Initial Tests

| Code | Description |

| A | Deionized water |

| B | Mildly alkaline (pH ca 11.5) |

| C | Mildly alkaline (pH ca 10) |

| D | Mildly alkaline (pH ca 9) |

Figure 1 (Ref. 4): Levels of Foil Erosion; Figure 2: (Ref. 4): Foil Erosion at Two Different Frequencies, Impact of Chemistry

Figure 3: Foil Erosion Versus Time (Ref. 4); Figure 4 (Ref 4): Foil Erosion Versus Percent Power

Barbara and Ed Kanegsberg founded BFK Solutions in 1994 as a critical cleaning consulting service and the go-to resource to make cleaning, surface quality, and contamination problems go away, or — even better — to avoid problems in the first place. Barbara, widely known as “The Cleaning Lady,” is an expert and trusted adviser in critical cleaning. Ed is known as “The Rocket Scientist.” They write Clean Source, an approximately monthly e-newsletter that provides practical ideas to improve cleaning, contamination control, and product quality. They are co-editors and contributors to the acclaimed two-volume “Handbook for Critical Cleaning,” CRC/Taylor & Francis, 2011. Visit https://bfksolutions.com

Note: Steve Norris is the New Project Director at Plasma Technology Inc. with locations in Torrance, CA, and Hartford, CT. He has had 13 years of experience in studying the effect of ultrasonic cleaning on metal surfaces to be used with engineered coatings.

References

- This article is adapted from: Steve Norris, Barbara Kanegsberg, and Ed Kanegsberg, “Ferris and Ultrasonics,” SPRAYTIME Magazine, Volume 21, Third Quarter 2014. For additional information about SPRAYTIME Magazine or about the International Thermal Spray Association, please contact spraytime@thermalspray.org

- Thanks to Crest Ultrasonics for providing the ultrasonics tanks for evaluation and to Ajit Shahani, eChem, for arranging for the transport of the cleaning equipment.

- We appreciate cleaning agents provided for evaluation by Alconox, Brulin, eChem, and Mirachem.

- B. Kanegsberg and E. Kanegsberg, “Is Ultrasonic Cleaning the Answer for Light Metals Finishing?” presented at SUR/FIN, June 9, 2014, Cleveland, OH.

- Kanegsberg, B., E. Kanegsberg, and S. Norris, “New Studies, Improve your Ultrasonic Cleaning Process, presented at SUR/FIN, Rosemont, IL, June 10, 2015.