There is a growing interest in conversion coatings based on titanium and/or zirconium as the result of the health and environmental issues associated with legacy chromate and phosphate conversion coatings.

Originally published: I. Milošev and G. S. Frankel 2018 J. Electrochem. Soc. 165 C127

Any alternative technology should be environmentally friendly and cost effective, and also able to achieve comparable corrosion resistance and paint adhesion for ferrous and non-ferrous substrates. Conversion coatings based on titanium or zirconium seem to fulfill many of these requirements and thus offer a great potential for further applications.

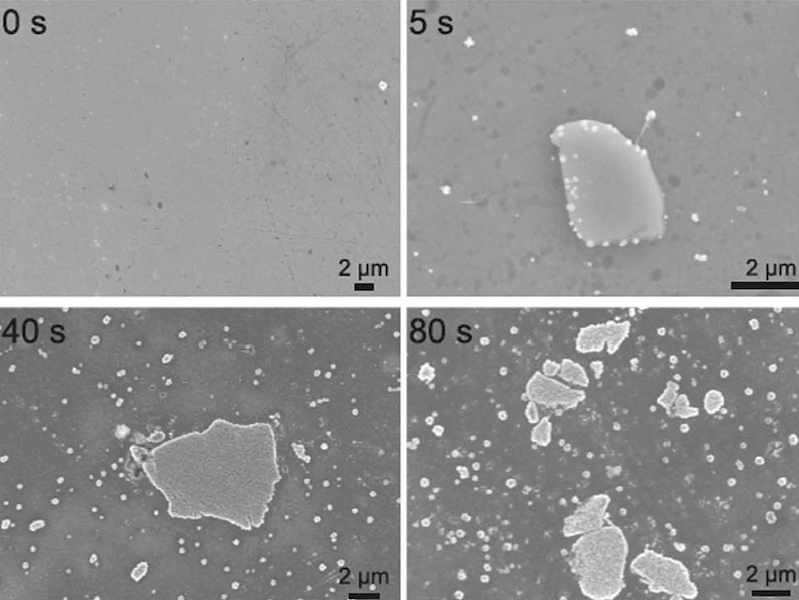

This literature (click here to download) review summarizes the scientific results in this rapidly growing area of research. Following the description of composition of conversion bath and deposition mechanism, the effects of process parameters for conversion baths such as pH, temperature, immersion time and agitation are presented together with coating characteristics. The effects of the type of substrate and substrate pre-treatment are explored for the most-studied substrates: Al alloys, zinc-coated steels and steels. Properties such as composition, morphology and thickness are summarized. The corrosion performance of the conversion coatings is discussed, as well as adhesion of organic coatings and delamination mechanism for a full coating system including substrate/coating/top-coat.

Click here to download the full paper

The collaboration between Jožef Stefan Institute and The Ohio University, Fontana Corrosion Center, was financed by Slovenian Research Agency as bilateral project between Slovenia and USA "Corrosion protection of technologically important materials using environmentally-friendly coatings" ID BI-US/15-16-006. The authors thank Ph.D. students U. Tiringer and G. Šekularac for technical help during manuscript preparation.