Automotive isn’t the only industry that has been slow to make the formal transition from hexavalent chromium to trivalent.

The aerospace industry is making a slow — but progressive — march towards fazing out hexavalent and using trivalent chemistries as more regulatory factors are increasing and pushing the carcinogen out of the industry.

Ted VentrescaTed Ventresca, President and Chief Operating Officer at chemical supplier Chemeon, says there has been progressing been in getting OEMs, primes, and shops to convert to trivalent chrome in the aerospace industry.

Ted VentrescaTed Ventresca, President and Chief Operating Officer at chemical supplier Chemeon, says there has been progressing been in getting OEMs, primes, and shops to convert to trivalent chrome in the aerospace industry.

Ventresca says it’s a combination of industry, environmental and regulatory goals that have been instrumental in moving the aerospace industry toward greater adoption of MIL-DTL approved trivalent chrome as a conversion coating and anodic seal.

“Certainly, the health and safety of the applicators at the OEM, MRO, process, or captive shop are paramount,” Ventresca says. “Also, for the military, the environmental sustainability of an asset across its lifecycle is a key driver. Trivalent chromium pretreatment — in a formulation that meets MIL-DTL specifications — is the environmentally safe, non-carcinogenic alternative to hexavalent chrome.”

Used in Anodizing, Sodium Dichromate, and Dilute Chrome

Hexavalent chrome has been used as an anti-corrosive in aerospace for 70+ years. Ventresca says it is described by industry in a number of different ways — including chrome 6, yellow or gold chemfilm, and its historical brand name Alodine — and used in anodizing, sodium dichromate, and dilute chrome.

“Regardless of what you call it, the harm to humans, animals, communities, and the environment caused by hexavalent chrome is well documented,” Ventresca says.

While the European Union was first to establish strict regulations associated with the use of hexavalent chrome — including the banning of parts coated with hex chrome from being imported into the EU — Ventresca says some of the EU sunset dates associated with military and aerospace usage of hexavalent chrome have moved, but the end is in sight.

“There is still more to be done on a national and global level,” he says.

So, what is the biggest reason holding them back from switching? Ventresca says existing OEM specifications that call out hexavalent chrome are associated with flight critical and mission-critical parts. The process to modify, change or deviate from a specification is vitally important and can understandably take time.

“There is rigorous testing and validation necessary to approve a MIL-SPEC trivalent chromium chemistry as a replacement to a legacy chemical,” Ventresca says. “Typical trivalent chromium chemistry hasn’t consistently met performance requirements on certain difficult alloys.”

A Number of “Must-Have” Elements Needed

Chemeon eTCP is the only MIL-SPEC trivalent chromium pretreatment.Through their work with OEMs, primes, and the military, Chemeon identified a number of “must-have” elements in order for an OEM, prime, or U.S. Department of Defense partner to have confidence in the performance and QC of trivalent chromium coatings, especially when replacing hexavalent chrome.

Chemeon eTCP is the only MIL-SPEC trivalent chromium pretreatment.Through their work with OEMs, primes, and the military, Chemeon identified a number of “must-have” elements in order for an OEM, prime, or U.S. Department of Defense partner to have confidence in the performance and QC of trivalent chromium coatings, especially when replacing hexavalent chrome.

Those requirements are:

- Superior and consistent corrosion protection performance on 2024 aluminum above all other trivalent chrome.

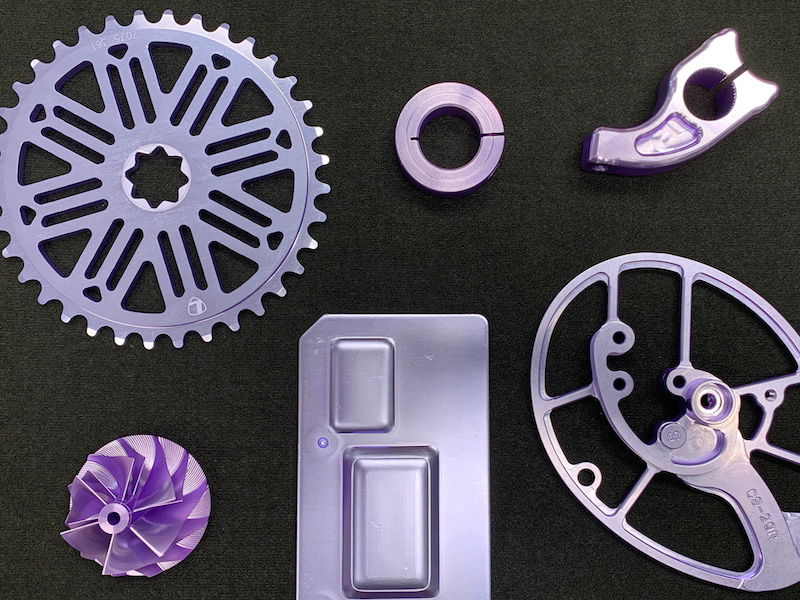

- Distinct color verifying parts are coated and protected.

- They must be approved for MIL-DTL 81706, TT-C490 Type VI, MIL-DTL 5541, and REACH and RoHS compliant, i.e., environmentally safe.

Given that information, Chemeon developed and patented the MIL-DTL, QPL approved CHEME Chemeon eTCP, the only MIL-SPEC trivalent chromium pretreatment to meet those needs.

“It literally checks the essential boxes needed for conversion,” Ventresca says.

Given the fact that there are replacements currently on the finishing market, where does Ventresca see changes coming in the aerospace industry over the next several years?

“In the near future, a lot more violet/blue hues of Chemeon eTCP replacing the existing yellow gold hue of hex chrome,” he says. “Ten years down the road, structures will be made out of a lot of different alloys and materials, and pretreatments will have to adjust accordingly.”

That is why Chemeon continues to forge alliances and collaborative research and development (CRADA) projects with aerospace OEM, primes, and military partners who view their expertise in corrosion protection as a vital part of a combined vision to provide solutions that meet critical goals while protecting people and the environment from harmful substances.