Larry Dietz takes a step back from marveling at the new barrel plating and electrocoat lines at Professional Plating in Wisconsin, and his smile grows wider.

Larry DietzIt’s not the new $4.5 million barrel plating system or the renovation of an existing line that has him grinning, nor the new ecoat system on full display in the brightly lit production floor, where the sun streams in from large windows not usually found in finishing shops.

Larry DietzIt’s not the new $4.5 million barrel plating system or the renovation of an existing line that has him grinning, nor the new ecoat system on full display in the brightly lit production floor, where the sun streams in from large windows not usually found in finishing shops.

What makes Dietz, the General Manager of the 200,000+ square foot Professional Plating in the beautiful hamlet of Brillion in Wisconsin, happy is seeing his 175 employees working diligently on their new equipment in an almost pristine environment.

“This is what happens when you buy them new machinery,” Dietz says, overseeing nearly $25 million in line additions and upgrades over the past 10 years. “When you give them the tools, they will understand that ‘Hey, this is for us to perform.’ We're not being asked to do something like MacGyver with duct tape and rubber bands or stuff like that.”

New and Refurbished Lines a Constant Happening

The new ecoat system on full display in the brightly lit production floor.Indeed, in what seems like an almost annual upgrade cycle of refurbished and new lines at Professional Plating, the new lines christened in July have the shop’s operations churning out finished parts faster and at even higher quality than ever.

The new ecoat system on full display in the brightly lit production floor.Indeed, in what seems like an almost annual upgrade cycle of refurbished and new lines at Professional Plating, the new lines christened in July have the shop’s operations churning out finished parts faster and at even higher quality than ever.

For Dietz, this is what he imagines when he visits the company owners, the Endries family, and proposes spending millions to replace or refurbish equipment at the 45-year-old company. He knows no amount of new equipment will improve sales unless the team is happy using it.

“We can't physically embrace them, but we can mentally embrace them,” says Dietz, who has also spent big money on employee lounges, quiet areas, and other staff amenities. “I don't want to sound cliche, but it's basically, ‘How can you not perform when you get all of the good stuff?’”

The new barrel line and refurbished one join a long list of projects that have been taking place at Professional Plating, which specializes in zinc coatings, ecoat, and powder coating applications for customers such as Harley-Davidson, John Deere, Ariens, Briggs and Stratton, and other major OEMs.

“For the first time in our 45-year history, we have redundant barrel capacity. Obviously, you can't just have one of something in our industry. It gets tough with downtime or just getting so busy.”

- 2022: Installed a new zinc rack plating system capable of finishing 10 racks of parts an hour at 288 square feet an hour. The 23 tanks included 15 for pretreatment, offering the capability to use multiple chromates and the same tooling that is standardized to its two largest zinc rack lines. The $4.5 million investment also included a major renovation and expansion of their quality lab facilities by 50%.

- 2018: The installation of a new zinc rack plating line cost $3.6 million and followed the renovation of a collaborative office center, with the old office space being turned into a 10,000-square-foot Work Lounge and Wellness Center for its staff.

- 2016: The facility added 60,000 square feet after moving an existing 10,000-square-foot building to a separate property offsite. The new space was used for a new zinc rack plating line to expand its capacity further.

- 2009: A 65,000-square-foot addition brought the overall space to 150,000 sq ft. This increased the facility’s shipping and receiving dock capacity while also increasing the storage area for finished products. The shop also added a new zinc barrel plating line.

Having the Size to Handle Customer Orders

The new barrel line and refurbished one join a long list of projects that have been taking place at Professional Plating.Dietz says about 35% of the parts finished at Professional Plating are shipped directly to the client's customers, so having large enough shipping and receiving areas—as well as a large warehouse to store the product—has been crucial to the company's growth.

The new barrel line and refurbished one join a long list of projects that have been taking place at Professional Plating.Dietz says about 35% of the parts finished at Professional Plating are shipped directly to the client's customers, so having large enough shipping and receiving areas—as well as a large warehouse to store the product—has been crucial to the company's growth.

In one of the most recent additions — the new barrel line and refurbishing of an older one —started up last December and took about six months to implement. The refurbished line was originally installed in 2009 and needed an upgrade.

“We reconfigured and renovated it and put all brand new barrel drives in,” Dietz says. “We pulled out the whole acid tank and put a new undercarriage in it. Years ago, these machines were designed so that you plunge the barrel in and let acid flow all over. That caused some issues over time.”

More importantly, the new and refurbished lines have given Professional Plating something that Dietz and his team have wanted for a long time: redundancy in case one line has a hiccup.

“For the first time in our 45-year history, we have redundant barrel capacity,” he says. “Obviously, you can't just have one of something in our industry. It gets tough with downtime or just getting so busy.”

Replacing a 30-Year-Old Ecoat System with New Technologies

The ecoat line has automatic chemical feeds, oil skimmers, and computer technology so precise it has 166 error codes to pinpoint any issues it may encounter. The epoxy ecoat line — which replaced a 30-year-old system — started construction in January 2024 and was more of a challenge, as contractors had to dig out the flooring of the production and drop the line deeper than it normally would be.

The ecoat line has automatic chemical feeds, oil skimmers, and computer technology so precise it has 166 error codes to pinpoint any issues it may encounter. The epoxy ecoat line — which replaced a 30-year-old system — started construction in January 2024 and was more of a challenge, as contractors had to dig out the flooring of the production and drop the line deeper than it normally would be.

But digging deep resulted in a unique ecoat system that allows the Professional Plating team to walk right up to the line and check how the line is running. The line is extremely visible and open, whereas visual access wasn’t easy in the past.

“You can walk up to it and look in it like an airplane,” Dietz says. “It's just super cool because it's right in front of you, so it has more access and visibility, and we just built a ton of safety into it.”

That includes automatic chemical feeds, oil skimmers, and computer technology so precise it has 166 error codes to pinpoint any issues it may encounter. The company is also working on other continuous improvement matters, such as rewiring parts of the facility, adding upgraded fire sprinkler systems, new venting equipment, and more.

New Software System Improves Efficiencies and Reduces Steps

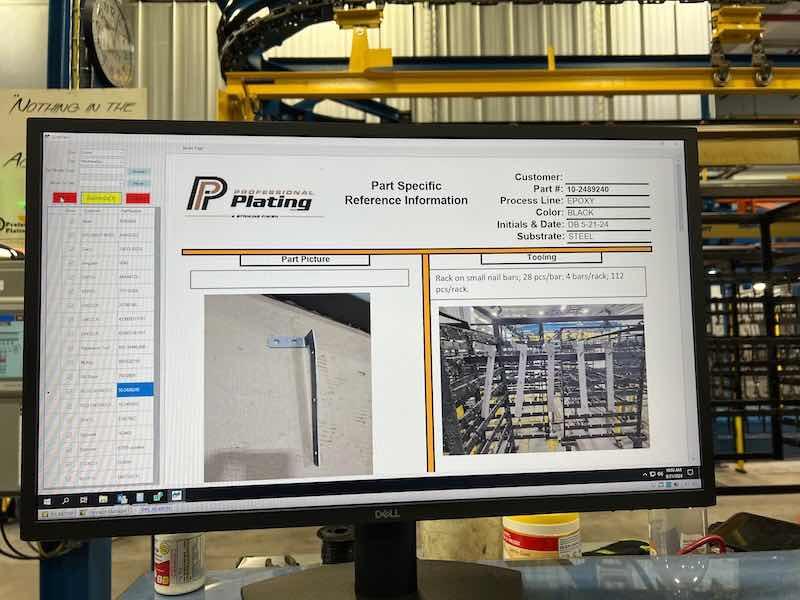

Dietz and his team picked a familiar-sounding software engineering firm, ProPlate, with which they have previously worked.To help run all of the technology and systems, Professional Plating has been working with a top automation software company to connect all operations, collect data, and troubleshoot where needed. Dietz and his team picked a familiar-sounding software engineering firm, ProPlate, with which they have previously worked.

Dietz and his team picked a familiar-sounding software engineering firm, ProPlate, with which they have previously worked.To help run all of the technology and systems, Professional Plating has been working with a top automation software company to connect all operations, collect data, and troubleshoot where needed. Dietz and his team picked a familiar-sounding software engineering firm, ProPlate, with which they have previously worked.

Alkesh Patel, President and CEO of ProPlate, says that with the new lines and equipment churning our coated parts all day, Professional Plating asked them to simplify work using less paper, improve the shop’s workflow methods, streamline come-ons, and have fewer steps for their system.

ProPlate's shop floor management software tracks orders at each processing step, and its streamlined quality assurance system is designed with ISO guidelines to ensure increased productivity in the shops.

“We were able to meet their needs with our 70/30 approach to right-sizing the software for them,” Patel says. “There is a 30% flexibility to customize to PPI’s need, and 70% industry standards and best practices with our secret sauce, which doesn’t change.”

“It's a scenario where we're just not lavishly spending money. We are 45 years old, and some parts of the building show that age.”

In addition, a powerful dynamic scheduling feature uses one comprehensive tool to create a dynamic schedule that updates at all stations in real time, thus eliminating the need to update paperwork continuously.

Unlike other software in the market, Patel says ProPlate doesn’t just run the shop floor but also focuses on the overall quality of the plant.

“It is designed and developed with a focus on plant quality and productivity,” he says. “With detailed data analytics, we can take a struggling plant to the next step, which is success for everyone.”

Planning for Expansion with a Purpose

Rectifiers from American Plating Power provide energy to run the finishing lines.Even with the new lines added in recent years — and the refurbishment of others to bring them in line with the newer ones — Dietz says every expansion and capital expense project over the years is carefully planned out and comes with an expected return on investment.

Rectifiers from American Plating Power provide energy to run the finishing lines.Even with the new lines added in recent years — and the refurbishment of others to bring them in line with the newer ones — Dietz says every expansion and capital expense project over the years is carefully planned out and comes with an expected return on investment.

“We don't rest often, but it's a scenario where we're just not lavishly spending money,” he says. “We are 45 years old, and some parts of the building show that age. Our thought is basically it will be what you take care of from a business standpoint.”

Kerry Behnke, who runs the zinc finishing operations for Professional Plating, oversaw much of the improvement projects for that area. Dietz kept an eye on the ecoat project as it was taking shape.

Dietz says it's a sharing and separation of responsibility. Still, the shop relies heavily on its business partners, whether it be the mechanical or electrical team, the air makeup specialists, the tooling people, or even Professional Plating’s own maintenance team, which helped supervise some of the projects as project managers.

With all the projects seemingly going on at the same time earlier this year — plus a staff of 175 team members still pushing through tens of thousands of parts per day — things were hectic but under control for a while in Brillion.

“It’s not slamming parts down, where you're potentially damaging parts. We could do more delicate parts. It’s little things like that where you change your abilities.”

“From last July to this July, it's been a good whirlwind,” Dietz says. “But we had good plans. We’ve done this before, and whether it was excavating the ground and then filling in the ground with our construction company or whether it's the floor people who come in and do the vinyl ester to protect it from chemicals, there is a pretty good recipe that we follow.”

Handling Additional Capacity to Meet Lead Times

Ecoated parts.Utilizing the new software upgrades from ProPlate, the Professional Plating team is working to ensure they can handle all the new capacity and service their existing customers in a timely matter. As they worked to break in the new lines, the team was also cognizant of making sure they were hitting marks for on-time delivery of parts and enhancing the quality that goes into each one.

Ecoated parts.Utilizing the new software upgrades from ProPlate, the Professional Plating team is working to ensure they can handle all the new capacity and service their existing customers in a timely matter. As they worked to break in the new lines, the team was also cognizant of making sure they were hitting marks for on-time delivery of parts and enhancing the quality that goes into each one.

Dietz says part of the planning process was making sure Professional Plating could deliver on its promises to existing customers and any new ones it decides to work with.

“We just don't go out and say, ‘Bring us your work,’ and then we sit there and back up their lead time because now we oversold,” he says. “We like to commit pieces, particularly on the barrel. We also like to commit to people like that, just like we commit to lead time. And if a company has 20,000 pounds a week and you can count on that, then we'll also count on that, and you'll get this lead time, we promise.”

That is because the new and refurbished lines have the latest technology to work as efficiently as possible. They have even designed the new system so that when parts are coming out of the barrel dumper, the bottom lift rises up to make the next dump gentler.

Dietz says that the design feature allows Professional Plating to finish more than just “nuts and bolts” and coat different parts than they might normally do in the barrel lines.

“It’s not slamming parts down, where you're potentially damaging parts,” he says. “We could do more delicate parts. It’s little things like that where you change your abilities.”

Plating, Ecoat, and Powder Coating Under One Roof

The epoxy ecoat line — which replaced a 30-year-old system — started construction in January 2024.The same can be said for the new ecoat line, which increases the part throughout rate and improves quality and stability. The older line was nearly three decades old, and Dietz knew they needed to overhaul the system to keep up with customer demand.

The epoxy ecoat line — which replaced a 30-year-old system — started construction in January 2024.The same can be said for the new ecoat line, which increases the part throughout rate and improves quality and stability. The older line was nearly three decades old, and Dietz knew they needed to overhaul the system to keep up with customer demand.

Having an ecoat line made Professional Plating a unique facility. It could move parts from the zinc line to the ecoat system to offer coatings that not many traditional plating operations could handle. With a powder coating system in the plant, the facility could handle just about anything customers asked it to do, and they have few competitors who can claim the same type of setup.

“The ecoat world in finishing is pretty lucrative, and it’s a pretty good return,” Dietz says. “Our equipment was 30 years old and our oldest asset. Yet it was one of our highest called-out orders. When we looked at how long we can keep racing that same car — and when you're trying to be the champion– we knew the new system increased the rack size by about 35%.”

“If we can get them to 30 days, then we can get them to want to come down Northway Drive every day and make this be a place they want to come to.”

Professional Plating can now do 8-foot parts, and the automation features—the oil skimmer, the auto chemical additions, and more—made it a worthwhile investment. With the newer tanks, they can pump cleaners out into tanks to look for parts instead of sending them directly into the wastewater, thereby controlling those expenses.

The older cure ovens worked at about 450°F, and the new line clocks in at 360°F. Dietz says they believe they can get it down to 350°F, which he calls a “phenomenal natural gas savings.”

Creating a Culture of Care and Employee Engagement

Dietz says it is a culture the management team works on daily to earn and maintain the buy-in of its employees.Meanwhile, Professional Plating recognizes that the source of its success is its 175+ team members, which Dietz and his management team work diligently on to keep them engaged and as supportive as possible. The company is heavily integrated into the Brillion community and continually supports charitable groups in the area, especially those that involve its own employees.

Dietz says it is a culture the management team works on daily to earn and maintain the buy-in of its employees.Meanwhile, Professional Plating recognizes that the source of its success is its 175+ team members, which Dietz and his management team work diligently on to keep them engaged and as supportive as possible. The company is heavily integrated into the Brillion community and continually supports charitable groups in the area, especially those that involve its own employees.

Dietz says it is a culture the management team works on daily to earn and maintain the buy-in of its employees who work on the finishing lines, in shipping and receiving, in maintenance, and in the front office.

Managers spend a great deal of time with new employees to keep them motivated and informed about the company's values. They also continue to look for new ways to support and advocate for them in company facilities and in the community.

“If we can get them to 30 days, then we can get them to want to come down Northway Drive every day and make this be a place they want to come to,” says Dietz, who, on this particular day, was getting in his pickup truck and taking a load of diapers donated by the staff to a place called House of Hope in Green Bay.

House of Hope is a home for unwed mothers in the area. The idea came from a Professional Plating employee who suggested they help the non-profit. Dietz says the time and energy they put into working with their employees, who have a personal connection to many charitable groups, is well worth the effort. The company has little turnover and often fills spots easily through employee recommendations to friends and family.

“If one of our employees is ever asked by someone, ‘How's it going at Professional Plating?” I never want them to say, ‘Oh, it's just a job,’” Dietz says. “If we give them reasons to let the bad stuff go out there and only think good here, they feel connected. And for the first time in some of their lives, it's the first time they've ever been connected to anything.”