No matter what I do in this business, there is nothing more satisfying to me than telling the story of entrepreneurship and ingenuity. And that all starts with the people who own and manage the coating and finishing shops in North America.

In this month’s digital issue of FinishingAndCoating.com, I am happy to bring you various stories about small to medium size shops who have grown through the only way I know of that is a proven success factor: through hard work and sheer determination.

I’m excited to bring you five such success stories in this issue, each one with its backstory of perseverance and long hours that have turned their operation into a successful one that employees several dozen, pays its taxes, and works with some of the top OEMs in the world to coat and finish parts.

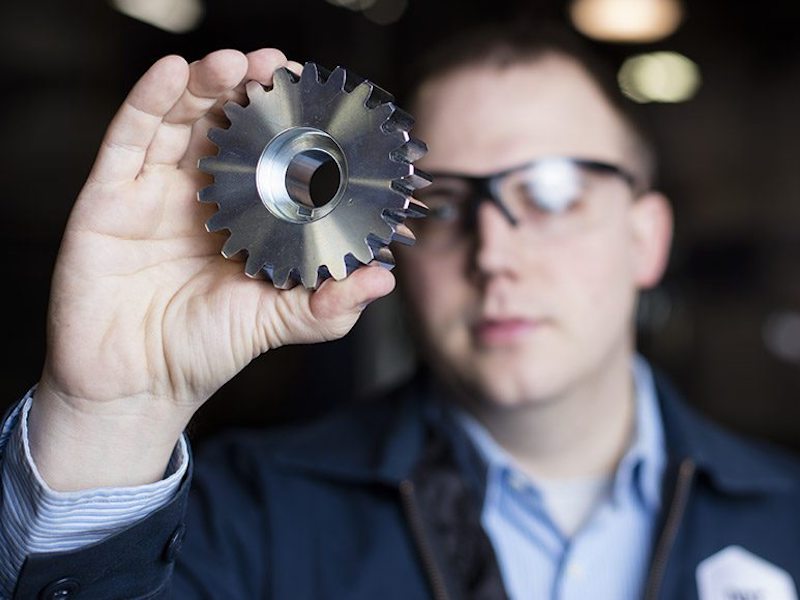

We start with Aaron Johnson at Oshkosh Plating Technologies, who was just a few years out of college and working in the chemical industry when someone told him about an opportunity to buy into ownership of a finishing operation. The now-president of the Wisconsin shop took over in 2013, and hasn’t looked back.

“I have been learning ever since,” says Johnson, whose shop provides zinc plating services to customers located in and around the Fox Valley area of Wisconsin.

Last year, Johnson launched Craft Custom Coating, a separate business run by Johnson that performs a Cerakote process. He says he took their experience and knowledge of metal finishing and started customizing one-of-a-kind pieces using Cerakote and hydrographics.

“We stand behind our work and have a ‘Covered by Craft’ warranty on all the work that we do,” he says.

We also profile Robby Harris and Steelville Manufacturing, which is booming and often needing to turn away business. Harris helped them start their in-house coating operation in 2013, and says he was ‘lucky enough’ to become processing general manager.

It’s vital work since 80% of the parts they make and coat goes directly to aerospace OEMs or their Tier-I suppliers. Harris says his happiest day at Steelville was when they passed their first Nadcap audit with only three findings.

“People in the processing industry had cautioned the owners for years that they would not be successful in processing,” he says. “My happiest moment would have to be that day that we proved them all wrong.”

Likewise, the future is looking ‘bright’ for the team at Technical Plating in Brooklyn Park, Minnesota. In the past two years, they have added an additional bright tin line, a second electroless nickel line, a bright nickel line, another passivation line and another reel-to-reel line, bringing their total to 17 lines.

Tyler Thomas, vice president and general manager, says the family-run company is bringing on new processes as the market is asking for them.

“We focus on communication with our customers, and developing relationships with them to attract and retain business,” Thomas says. “The attention to detail, flexibility, and unmatched customer service has been a large factor in our growth.”

We also tell the story of Terry Wallace and his company, H&T Industrial Spray. Terry’s father, Hack, had $1,000 that he had borrowed, and started a weekend painting business with his son back in 1990 in Francisco, Indiana.

Growth is also in the air for their industrial powder and liquid coating operation. Recently, H&T Industrial Spray added iron phosphate treatment and a steam machine to their stable of offerings, and have some additional expansion plans.

“Our plans in the next few years is to update to a large media blasting hut and update the size of our oven to meet the needs of much larger industrial needs,” Terry says.

We also showcase Great Lakes Metal Finishing in Erie, PA. Owner Dennis Hartwig was looking for a business opportunity in 1994, and, like Johnson at Oshkosh Plating, found an opportunity to buy into as plating operation, although his financial advisors told him it wasn’t a wise move.

“He thought that I was crazy for getting back into this business,” says Hartwig. “Here I am, some 26 years later, and still expanding our capabilities in using zinc and zinc nickel to provide corrosion protection to manufactured parts made throughout the world.”

These are true American success stories. It’s not to say these owners are the sole reason for their growth, and each will tell you they have a great team. But telling their stories is what I enjoy most about writing for you all.

Five shops, and five success stories. It makes you wonder who out there is just now getting into the coating and finishing business, and what lays ahead for them, too. I just hope I am there to tell their stories, too.

Tim Pennington is Editor-in-Chief of Finishing and Coating, and has covered the industry since 2010. He has traveled extensively throughout North America visiting shops and production facilities, and meeting those who work in the industry. Tim began his career in the newspaper industry, then wound itself between the sports field with the PGA Tour and marketing and communications firms, and finally back into the publishing world in the finishing and coating sector. If you want to reach Tim, just go

Tim Pennington is Editor-in-Chief of Finishing and Coating, and has covered the industry since 2010. He has traveled extensively throughout North America visiting shops and production facilities, and meeting those who work in the industry. Tim began his career in the newspaper industry, then wound itself between the sports field with the PGA Tour and marketing and communications firms, and finally back into the publishing world in the finishing and coating sector. If you want to reach Tim, just go