There is a huge difference between fads and trends. Fads are what you did with your hair and your jeans back when you were a teenager. Trends are what you need to get ahead of if your business is going to succeed.

Since I am an expert in absolutely nothing, I called on 30-40 of the top powder coating applicators in North America to gauge their interest in what trends they were seeing, and more importantly, what other coaters needed to be aware of to run their shops successfully.

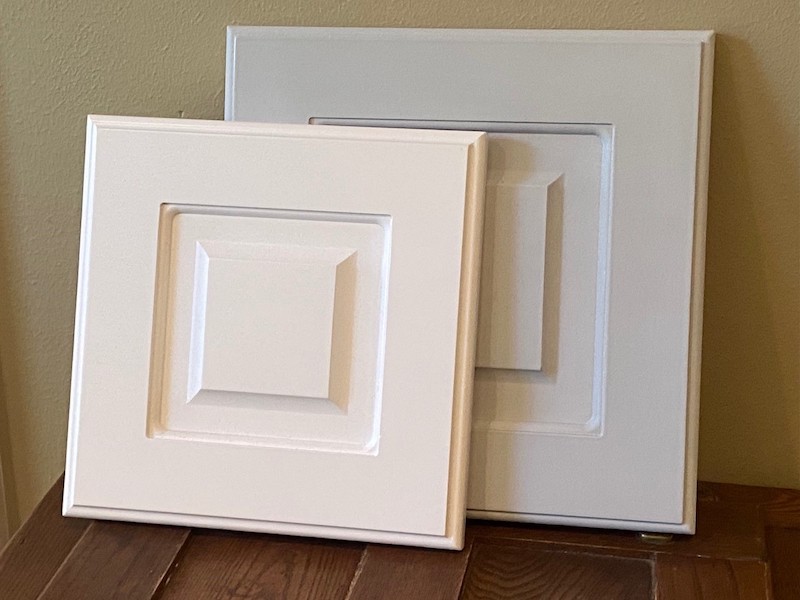

Overwhelmingly, I heard time, and again that powder coating on wood and MDF substrates was a trend that more shops were seeing. We’ve often heard this tune going back several decades that powder coating on wood and MDF was going to be the next rage in the finishing industry.

The problem was the technology just wasn’t where it needed to be when it came to getting the job done. Coating on wood and MDF is tricky because you need something for the current to ground too, and MDF just didn’t have enough of it. The second problem was insufficient to control the coverage and thickness of the MDF. The final issue was how to cure the wood and MDF in low enough temperatures that the coating was permanently affixed to the surface without warping or damaging the wood/MDF substrate.

But several years ago, a strange phenomenon happened in the powder coating world: coating suppliers started talking with application equipment makers who brought in the oven and cure specialists to see if they could all connect the dots and make coating on wood and MDF a possibility.

In this issue, I speak to several big names in the powder coating industry to see how they were able to all come together and get a better system in place for powder coating wood and MDF. It is a wonderful accomplishment of cooperation and ingenuity and something that has made me more hopeful than ever that coating on wood and MDF might be something that could finally take off.

If so, then it gives powder coaters more power to bid and win contracts for cabinetry, furniture, and other coatings that were mainly utilizing liquid applications. That would be a win for a lot of shops and suppliers in the industry. Let’s hope it happens soon. Knock on wood.

Tim Pennington is Editor-in-Chief of Finishing and Coating, and has covered the industry since 2010. He has traveled extensively throughout North America visiting shops and production facilities, and meeting those who work in the industry. Tim began his career in the newspaper industry, then wound itself between the sports field with the PGA Tour and marketing and communications firms, and finally back into the publishing world in the finishing and coating sector. If you want to reach Tim, just go

Tim Pennington is Editor-in-Chief of Finishing and Coating, and has covered the industry since 2010. He has traveled extensively throughout North America visiting shops and production facilities, and meeting those who work in the industry. Tim began his career in the newspaper industry, then wound itself between the sports field with the PGA Tour and marketing and communications firms, and finally back into the publishing world in the finishing and coating sector. If you want to reach Tim, just go