Throughout industrial history development, four great moments can be identified that have marked benchmarks in which the platform — on which humanity has promoted the manufacture of objects for commercial purposes — has been revolutionized.

Pedro CastilloThese are known as the four industrial revolutions that have marked a turning point in mankind as a result of the constant innovation and development of technologies in accordance with the needs of each historical moment.

Pedro CastilloThese are known as the four industrial revolutions that have marked a turning point in mankind as a result of the constant innovation and development of technologies in accordance with the needs of each historical moment.

The four revolutions are:

- 1.0 – Mechanization / hydraulic and steam power/railway

- 2.0 – Mass production lines using electrical energy

- 3.0 – Automated production / computers / electronics / Information Technology

- 4.0 – Internet of Things / Cybernetic Physical Systems / Networks / Machine Learning

Industry 4.0 represents the integration of algorithms and networks with machines, equipment, and systems to create an information environment in real-time that facilitates decision-making towards operational perfection.

It is based on what is known as Data Science, which is a multidisciplinary field combining processes, algorithms, scientific methods, and software whose objective is to create knowledge and generate a data-based perspective that allows decisions to be made, automatic or dependent on humans, in order to trigger actions for the benefit of a process or application in question.

Main Characteristics, Aspects, and Realities

Industry 4.0 has peculiar aspects and owns an indisputable reality, something that each person feels so close to and, at the same time, so far away given its contradictory simplicity and great complexity.

What can be highlighted is that this term is not a futuristic topic; it is a reality since it is already happening in various industries.

Today there is an immense amount of information available as a result of the advances that allow the devices being developed to provide it with a good degree of detail in real-time, for which industry 4.0 is presented as a tool that facilitates the quick processing of all this information.

It promotes sustainability, especially in processes with very high repeatability within a finite universe of options, allowing specific automatic decisions to be made, although the recommendation is that the final decision is always to be human.

Something of great importance that must be considered is that the learning process of the 4.0 processes is iterative; it is not instantaneous. Many companies offering equipment upgrades to a 4.0 platform project a wrong impression by inferring results will arrive immediately after implementation; in reality, the upgrade is the first step on a long road. All 4.0 processes support crucial decision-making, mostly not high-impact decisions.

Effects and Perceptions

Industry 4.0 technologies are intimidating for those who walk into this arena for the first time, especially is intimidating for high-level executives and engineers, who are not aware of the new technological trends, and, on many occasions, this topic is devalued and attacked for fear of feeling devalued and seen as ignorant before the work environment that surrounds them.

Industry 4.0 is an attack against the art of traditional processes; it offers parameter standardization mechanisms that move away from old-school-style sentiment adjustments, most of the time getting rid of the feeling approach. Much opposition is voiced by those who have operated processes for decades that, for the first time, have the option of holding steady against moving benchmarks. It creates a feeling of dehumanization of the processes, less dependency, and greater analysis.

Speaking of feelings, by way of analogy, 4.0 processes could be expressed as a tool that promises less romance but much more love, translated into less complex resolutions and better results. Most experienced people enjoy the resolution process in pursuit of the desired result.

The biggest reality is that upgrading equipment to industry 4.0 requires having a very deep knowledge of the equipment, the process, and the product. The main objective is to keep the active interaction of these three components aligned and coordinated.

The Approach of Industry 4.0 to Benefit the Surface Finishing Industry

Industry 4.0 technologies focus on six main perspectives that provide the greatest benefits to users who decide to update their processes to this platform. It should be clarified these points are not the only ones, and it depends on the needs of each user that these points can be more or less than the ones mentioned in this document. These are the six perspectives:

- Equipment

- Process

- Product

- Quality

- Cost

- Overall Equipment Performance

The main sources of information and variables are the Equipment, the Process, and the Product, while the Quality, Cost, and Overall Equipment Performance are the main operating guidelines within compliance and optimal maximization points.

The following figure shows a correlation between the sources of variables and the operating guidelines mentioned above, showing their focus points, their sponsors (at any given company), and the natural objectives that most 4.0 processes seek to optimize.

| Source | Focus | Sponsor | Objective |

| Equipment | Performance | Maintenance | Maximize Equipment Economic Lifecyle |

| Process | Productivity | Production | Maximize Flexible Production Capacity |

| Product | Zero Defects | Quality | Compliance on Customer Requirements |

The keywords to highlight are “maximize” and “compliance,” which are the fundamental basis of the objectives that every 4.0 process must have to be considered as such, and not just as a showroom-type feature.

Universal Considerations

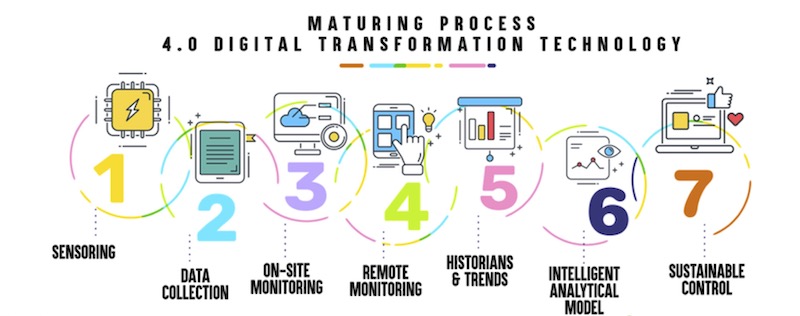

Patience is a must; a lot of patience. Implementing 4.0 processes, especially in the surface finishing industry, requires patience and understanding that a 7-step maturity process exists for every equipment, process, and product. It should be analyzed to what extent added value is generated for each source of information staging at a determined step; achieving the seven steps is not synonymous with maximum added value.

The implementation must be step by step; it cannot take an accelerated or hasty pace; it is required to know how to combine the analysis of benefits with the details of each equipment, process, and product involved. It should be kept in mind that it is an iterative process; the results are not, and cannot be, instantaneous. There should be room for learning the 4.0 process by the users directly involved.

Surface Finishing Industry and its points of interest when using industry 4.0

The main approaches related to the equipment, the process, and the product were mentioned, which are of total interest to the surface finishing industry. Each of these approaches and the considerations that users in this industry should pursue to achieve maximum and compliant results are described in detail below.

Performance

You must have a broad knowledge of how the equipment operates in each manufacturing scenario, knowing how each variable is associated with all known problems related to the process and the product. Experience at its fullest is grounded in cause-effect correlation, not just witnessing something happen at some point and cause something.

Developing an advanced analytics model is essential; it must be done in order to process a large amount of information and be the basis of some behavioral predictive model that correlates various behaviors with possible effects; feeding the intelligent learning of the 4.0 model is essential for those who They seek to take their processes to levels of maximum efficiency and use.

Within this approach, a primary objective is to be able to predict and prevent out-of-control situations, which are those that lead to high costs and defects. The approach also strives to achieve optimization in the consumption of resources and energy. There are companies with clear objectives aligned with their environmental commitments, so being able to demonstrate their achievements in real-time is of vital importance.

Productivity

The ability to track production orders in real-time is a feature that is very well used in companies, especially those that have very flexible processes and that offer a responsive service to customer requirements. The monitoring of production orders within a process, but also being able to find them in each of the various stages, for purposes of information in real-time, as well as to determine relevant information in the future according to the variables of process present during its manufacture.

Process optimization, especially in flexible processes, is a basic requirement to achieve optimization of the manufacturing cost, which goes hand in hand with the measurement of productivity according to the mix of products produced, allowing simulations to be carried out to help decide the best scenarios and/or predict the impacts of force majeure decisions.

Quality

One of the main approaches is to be able to associate the performance between the equipment, the process, and the product, as the glue that unites these three sources of variables. For quality purposes, Industry 4.0 is a powerful tool in root cause determination in defect investigation. The recipes to produce the processes must have certification or approval by Quality in order to be launched without having to keep a watchful eye on each of the variables, recipes that are a guarantee of quality. This tool produces the necessary information to support the decisions that are made.

One of the main approaches is to be able to associate the performance between the equipment, the process, and the product, as the glue that unites these three sources of variables. For quality purposes, Industry 4.0 is a powerful tool in root cause determination in defect investigation. The recipes to produce the processes must have certification or approval by Quality in order to be launched without having to keep a watchful eye on each of the variables, recipes that are a guarantee of quality. This tool produces the necessary information to support the decisions that are made.

Quality is closely linked to innovation issues since new products are always sought to be developed in compliance with the requirements from the first moment, so an approach that the finishing industry has based on industry 4.0 is the simplification of new product launch programs, seeking to inject information from existing success stories and can serve as a guide in some extrapolation of results.

As in the Productivity approach, in Quality the development of advanced analytical models facilitates the prediction of defects, these being aimed at learning the behavior of the variables with their direct correlation to the quality parameters of each product, process, and equipment.

From the beginning of the surface finishing industry until today, it has been possible to develop procedures and manual standards that, with strict monitoring and application of these, can maintain control of the parameters that allow compliance with the requirements of productivity, quality, and performance. Industry 4.0 comes to simplify efforts by being able to take information, process it, and display it in real-time, with the characteristic that those involved in the process go from being parameter adjusters to information analyzers, making use of experience and mathematics to optimize processes.

The pride of being able to master these parameters with discipline, and achieving desired results, often becomes the main obstacle that blinds executives and engineers from seeing the benefits that the 4.0 platform can bring them and take their high-performance operations to the next level. Today it is a novelty, but like many technological advances, it is very close to becoming a basic requirement. Evolving at the pace of innovation is healthier and more organized than having to transform at the pace of being on the verge of operational obsolescence. Cases in the world abound through time and industrial revolutions.

Within the surface finishing industry, platforms 4.0 have a wide variety of options where they can be applied, the most active being the following:

- Surface Finishing Equipment

- Water and Waste Treatment Systems

- Ovens and Furnaces

- Material Handling Systems

- Peripheral components

Impacts on the Surface Finishing Industry

The desired impacts in this industry can be described in the following points, clarifying that they are not the only ones but rather the ones most sought after by the users of these support technologies:

- Improvement:Achieve extraordinary response and resolution times for troubleshooting situations.

- Optimization:Achieve flexibility, productivity, and quality compliance.

- Accuracy:Detection and diagnosis of anomalies in the equipment, the process, and the product. To achieve root cause analysis with zero recurrences of events.

- Know-how retention:To increase the knowledge transfer dynamics from retiring expert employees to new employees, along with standardization perfection. AI Algorithms, along with historical databases, are the perfect recipients with information available for R&D, learning, and case studies development. This one is primarily important as human involvement is always mandatory for this industry.

- Proactive work environment:people involved and around industry 4.0 platforms develop an improvement culture as most of the information is used to predict issues and transform the process into a self-learning environment.

- Reliability Centered Maintenance (RCM):to feed all the efforts to maximize equipment reliability while minimizing life-cycle cost.

- Organizational Culture:As mentioned above, this is impacted positively by creating a proactive work environment towards achieving goals on performance, productivity, and quality. Also has some negative impact if this is not managed properly; this will be mentioned ahead of this document.

- Top Management:This could be a revolution for top management if this is not treated with professionalism and modesty. Young talents pick these platforms up faster and easier than most experienced talents, which could lead to awkward moments and discussions, as well to sabotage. Organizational Culture is essential to be well established, as this type of innovation usually challenges the status quo, and surprises could happen. However, when Top Management knows how to get the best out of these platforms, results are observed towards a lean organization which easily is observed by its industry, which also includes its customers.

Going deeper on the impacts on the Organizational Culture and Top Management, together, we find the following topics that must be taken into serious consideration to avoid negative impacts.

- Finishing System Operators:should be trained to become more data analysis oriented. Unsupervised Platforms 4.0 drive a correlation on the increase in process control versus the decrease in process sensibility, as a result of the operators stepping away from the system operations and focusing more on the virtual control/supervision now they have over the operation.

- Finishing systems require human physical presence as they are still attached to human senses as smell (cured parts), sound (pumps, motors), and touch (product surface), to name a few examples, which are a fundamental part of their experience.

- Management:information available can be used to develop risk mitigation plans, as part of the trend analysis, with decision triggers for operators to act when required. However, moving into 4.0 technologies usually causes anxiety in management as it takes time to understand the timing in the process of adaptation and knowledge transfer. As a result, in the reflex act, micro-management could appear as an intention to make good use of the new information available.

- Company Strategy:Industry 4.0 offers a wide variety of uses and could be extended as far as desired, so for this, each company should analyze these possible extents on their value chain, their supply chain, and, especially, their regulatory compliance. ERPs and other peripherical software allow one to take a process beyond its physical limits.

On this same page of company strategy, cybersecurity has never been more important as 4.0 platforms can be a welcome mat for hackers and mad hatters. Going beyond the added value could bring the requirement of expensive preventive solutions. Everything is possible, but all perspectives must be considered.

Key Elements for Successful Implementation

Here is the golden rule for the finishing industry: Industry 4.0 is not a solution; it’s a tool.

Here is the golden rule for the finishing industry: Industry 4.0 is not a solution; it’s a tool.

We must take into consideration that a finishing system is a complex array of equipment working in sync, most of the time, and is not perfect. There’s always something, somewhere, failing someway, somehow. As a part of this equipment array, industry 4.0 comes into place looking to be capable of interconnecting with all desired equipment and beyond.

For a successful implementation, the very first step is to define what you would like to have a read on: Equipment, Process, Product, Quality, Cost, and/or Overall Performance.

Although it is nice to say “all of the above,” it is important to understand the implementation cost is directly related to the control features scope (variables to read/analyze), as well as the maintenance cost that comes attached. The more information to analyze, the larger the space required to store all that data, and more complexity should be added to the algorithms that would be processing the information, as well as more complexity to the analytics model to be developed.

The finishing system engineering comes to play as a key element; you must realize the type of manufacturer is the one who designed, built, and installed your system: a System Integrator, an Engineering Firm, or a vertically integrated company.

The nature of the system engineering, along with the availability of key information, can take a 4.0 platform to successful levels or make it quite impossible to implement without first performing a very expensive gathering of information labor. Some companies have faced this scenario, understanding that saving some dollars on a finishing system could mean acquiring a system that can’t be upgraded, at a reasonable cost, in the future.

The main reason is related to the reliability of the components installed in the system if these can be used on the upgrade or should be replaced, as well as the quality of the engineering of the system as some modifications should be performed to avoid “noise” on the data to be generated.

About the Vendor to be Selected for an Implementation

A very important topic. The IT industry has a wide variety of companies with expertise in 4.0 Platforms, with technical capabilities to build the most complex tailored tools. Data Scientist is the term for SMEs in this technical capability.

Data Scientists are required; however, here’s the next question to ask: is it also a Finishing Industry expert?

All vendors ready to pitch their Data Science capabilities should be challenged on their finishing systems knowledge. Here are a couple of quick recommendations:

Measure the level of involvement required from the company to work along with the vendor: Time + Knowledge + Level of equipment, process & product rationale.

Vendors must be tested on their knowledge related to the finishing industry. Its level of knowledge and experience is directly related to its ability to explain, describe and teach about the finishing system the vendor would be upgraded without any help or assistance. Its level of detail is important.

There are more recommendations when evaluating vendors; an entire document can be developed on this topic.

Summary

Industry 4.0 is a tool developed to maximize a surface finishing solution. It’s a combination of technology, experience, and strategy that is required for successful implementation and results in enhancement. It’s an iterative process with a learning curve that can’t be accelerated. When companies have a strong organizational culture, these types of tools promote a proactive work culture, among other benefits across the organization, as well as powerful reasons to establish clear guidance and top management commitment to avoid a process sensibility detriment by the system operators.

Human senses can’t be taken for granted as these add final value to the process, as industry 4.0 is only a tool to support final human decisions. Even if the final decision is approved, it must be human. Successful implementation is in the company’s hands, not its vendor’s hands, as involvement is mandatory to achieve the maximization of results and compliance with customers’ requirements.

About the Author

Pedro Castillo is currently Managing Director for Mexico & LATAM at Therma-Tron-X, Inc. and has more than 25 years of experience in the metal-working industries. He is a Mechanical Engineer from Monterrey Tech (ITESM Campus Monterrey) and has a master’s degree in science with a major in Manufacturing Systems from Monterrey Tech (ITESM Campus Monterrey). Pedro is an active member of CCAI, an education board member of PCI, a communication board member for AMAS (Mexican Surface Finishing Association), and an active member of SME. He’s an active speaker on selected specialized topics related to Industrial Marketing, Industry 4.0, and Surface Finishing technologies, among other topics. Pedro holds certifications in Electrocoating, Powder Coating, Six Sigma, and Lean Manufacturing and has completed business leadership programs at Dale Carnegie and the University of Cambridge. He is a member of diverse boards of directors for companies and initiatives in Mexico and the United States. He can be reached at pcastillo@ttxinc.com and visit Therma-Tron-X at www.ttxinc.com