The metal finishing industry has a multitude of different safety exposures, from physical hazards such as lifting and overhead cranes to the chemicals used in the processing of materials.

Alex MillerSoft tissue injuries account for a great many of the injuries sustained in this world, but one aspect that often gets overlooked is the ergonomics of Fine Motor Skills and Micro-Manipulation activities.

Alex MillerSoft tissue injuries account for a great many of the injuries sustained in this world, but one aspect that often gets overlooked is the ergonomics of Fine Motor Skills and Micro-Manipulation activities.

Ergonomics is simply a technical way of saying there is a way of making the task fit the human body instead of making our bodies fit the task at hand, and with repetitive motion, those uncomfortable positions become detrimental. Many different industries, including the metal finishing trade, have successfully implemented ergonomic solutions in their operations as a way to address these types of injuries, which include modifying existing equipment, making changes in work practices, and purchasing new tools or other devices to assist in the production process.

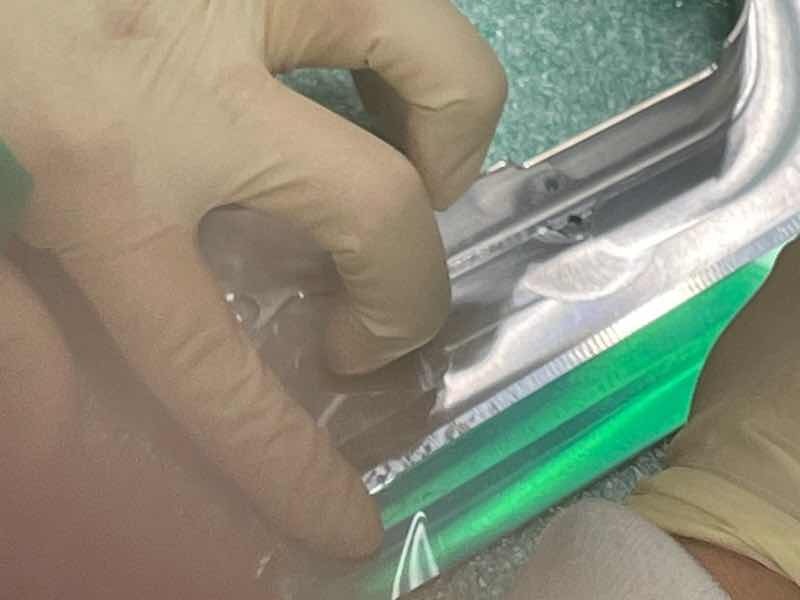

Pincer GraspThese changes can reduce physical exertion and unnecessary movements and can even help reduce employee turnover. However, one set of tasks in our industry has occasionally been overlooked: the people who work in the area of masking, taping, racking, and other tasks that use what is called “Fine Motor Skills and Micro-Manipulation,” which include much of the detail work that these employees are engaged in.

Pincer GraspThese changes can reduce physical exertion and unnecessary movements and can even help reduce employee turnover. However, one set of tasks in our industry has occasionally been overlooked: the people who work in the area of masking, taping, racking, and other tasks that use what is called “Fine Motor Skills and Micro-Manipulation,” which include much of the detail work that these employees are engaged in.

We will discuss the details of what that operation entails and what we can do to minimize the exposures they face on a daily basis.

What are Fine Motor Skills and Micro-Manipulation?

Finger IsolationFine Motor Skills and Micro-Manipulation are the movements and actions of the hands, fingers, and wrists that require precision and dexterity of movement. These fine motor skills can be broken down into different components and movements.

Finger IsolationFine Motor Skills and Micro-Manipulation are the movements and actions of the hands, fingers, and wrists that require precision and dexterity of movement. These fine motor skills can be broken down into different components and movements.

These movements explain specifically how the employee uses their hands to accomplish these detailed tasks. With respect to the metal finishing industry, a portion of the job is masking, prepping, and mounting and involves very small parts, which require a great deal of dexterity and Micro-Manipulation of materials and fingers/hands.

The specific activities or movements can be grouped into specific actions and are described as follows:

Thumb OppositionPincer Grasp: Pincer grasp refers to the pad-to-pad grip needed to pick up small objects. The pincer grasp is important for many fine motor tasks. Any functional skill that involves holding items between the thumb and index finger is based on the effective development of a pincer grasp.

Thumb OppositionPincer Grasp: Pincer grasp refers to the pad-to-pad grip needed to pick up small objects. The pincer grasp is important for many fine motor tasks. Any functional skill that involves holding items between the thumb and index finger is based on the effective development of a pincer grasp.- Finger Isolation: Finger isolation is the ability to isolate and use the fingers one at a time in functional tasks. Finger isolation is using one finger to perform a task. Pointing with the index finger and moving all of the fingers independently is considered finger isolation.

- Thumb Opposition: When opposing the thumb to the fingers, small objects are able to be held and manipulated. When opposing, the thumb’s thenar muscles work to advance and position objects, such as holding a pencil when writing, managing a button with ease, and pulling a zipper.

Tripod GraspTripod Grasp: Tripod grasp is the opposition of the thumb to the pad of the pointer finger and middle finger when grasping and manipulating objects. Tripod grasp is the optimal (though not the only functional) grasp used to hold and write with a pencil, for example.

Tripod GraspTripod Grasp: Tripod grasp is the opposition of the thumb to the pad of the pointer finger and middle finger when grasping and manipulating objects. Tripod grasp is the optimal (though not the only functional) grasp used to hold and write with a pencil, for example.- Bilateral Coordination: Coordinated use of both hands together, or using one hand as a stabilizer and one hand as a manipulating hand. Bilateral coordination includes three components: symmetrical movements, alternating movements, and dominant hand/ supporting hand movements.

Identifying the Hazards

Bilateral CoordinationFrom Masking operations to rack mounting, the tasks can vary with each individual operation, company, and even trade. The task of identifying the hazards related to this detailed work is not much different than identifying other hazards in the company.

Bilateral CoordinationFrom Masking operations to rack mounting, the tasks can vary with each individual operation, company, and even trade. The task of identifying the hazards related to this detailed work is not much different than identifying other hazards in the company.

When we are talking about soft tissue hazards, however, one solution historically has been used to great success with the prevention of strains and sprains across all industries. It has had documented success over the years with very little argument to the contrary (its implementation has always been its Achilles Heel, which is also undisputed). It is a Stretching Program, otherwise known in the industry as the “Stretch N’ Flex” program.

These stretching programs are typically used to warm people up in the morning before employees begin their day so that the large muscle groups do not start cold, which is the cause of many sprains and strains. The success of that program, however, is exactly where it falls down for our people who are doing the Fine Motor Skills and Micro-Manipulation activities.

Those programs focus on the large muscle groups that are used for lifting, bending, and reaching, and as effective as they are in that operation, there are few to no stretches for the very small muscle groups involved with the Fine Motor Skills and Micro-Manipulation movements.

A Valuable Tool in Addressing This Shortcoming

Leavitt Pacific’s Safety Services Division has developed a program that addresses that shortcoming. Our “Fine Motor Skills and Micro-Manipulation” program is a valuable tool in addressing this shortcoming.

In addition to an educational resource (that could easily be developed into a training module for those specific employees) that describes some of the types of grasps, there is an evaluation tool that can assist with the determination of what specific grips are being used for each task, which leads to specific stretching exercises so that a customized stretching plan can be developed for these employees, and can also be used to alleviate discomfort that might occur from overuse or misuse.

The stretching exercise page could be posted in the area where these tasks are being performed as a reminder. This program can absolutely help minimize soft tissue strains and sprains of employees conducting Fine Motor Skills and Micro-Manipulations, as well as help the company develop procedures to address Repetitive Motion injuries.

Download the Tool

You can find this Fine Motor Skills and Micro-Manipulation Tool on our Leavitt Pacific Safety and Risk Management Resource Page. Please feel free to go there and download the tool to use as you see fit. There are also many other useful safety resources available from us, such as our Risk Management Center and our Ergonomic Evaluation Program. Let us know if you have any questions or are interested in learning more.

This resource included in the tool mentioned above is also the beginning of a larger process, and the “Evaluation” page can assist with the start of it. This is called a “Job Hazard Analysis” and has become a common practice and a standard in the industry. You may be familiar with the term, and as you may know, many customers and clients are starting to require these in the specifications of a job.

It all begins with observation of the steps associated with a task and the hazards related to each step. If you would like to learn more about a JHA, please contact your Leavitt Pacific representative, and we would be happy to educate your organization about this process and how it can be applied to any company’s operations.

Click HERE to download https://www.leavitt.com/leavittpacific/docs/NEWS_RMB_Fine-Motor-Activities_3-10.pdf

Alex Miller, ARM, OHST, is the Director of Safety Services at Leavitt Pacific Insurance Brokers in San Jose, California. Email him at alex-miller@leavitt.com and visit https://www.leavitt.com/leavittpacific/