Hitachi High-Tech Analytical Science, a global company within Hitachi High-Tech Group, has introduced a new software update for its thermal analyzer product range that improves workflow efficiency by automating measurement conditions input, analysis and data export.

With many companies increasing their use of thermal analyzers for research, development and monitoring quality of various materials, the software update minimizes user errors and helps provide results you can trust.

Automatic Entry of Measurement Conditions

As measurement conditions like temperature range and heating rate vary from sample to sample, human errors such as inaccurate input and misread analysis results can be introduced. The Hitachi software update introduces a feature that allows measurement conditions, which previously needed manual entry, to be entered automatically by reading identification information linked to a sample with a barcode reader.

This feature can also be used in conjunction with an autosampler to automatically test a larger volume of samples, helping to eliminate human error when entering measurement conditions and improving data quality.

Data Management Support

When a high volume of samples needs to be analyzed, time and labor costs associated with extensive data entry and managing high volumes of results brings additional challenges. Our new data management feature allows information such as test items, lot numbers and serial numbers to be exported together with thermal analysis results data. This information can be exported to CSV, Excel and text formats, making management of analysis results easier and simplify transfer to data handling systems such as LIMS. This all contributes to improved results reliability during quality control and research and development.

When used in conjunction with Hitachi High-Tech's automatic analysis software, not only can post-measurement analysis be carried out automatically, but administrative data and analysis results can also be exported as data sets in an easy-to-manage format.

By preventing human error during configuration of measurement conditions, management of analysis results data is made easier, leading to increased reliability and efficiency.

“We’re always looking to improve the user experience of our instruments,” says Olivier Savard, Product Manager for Thermal Analysis. “This latest update to our thermal analyzer product range helps us support customers with their increasing data management needs, eliminating human errors and increasing data reliability.”

Hitachi High-Tech Analytical Science is a global company within the Hitachi High-Tech Group. The company is headquartered in Oxford, UK, with R&D and assembly operations in Finland, Germany and China, and sales and support operations around the world. Our product range includes:

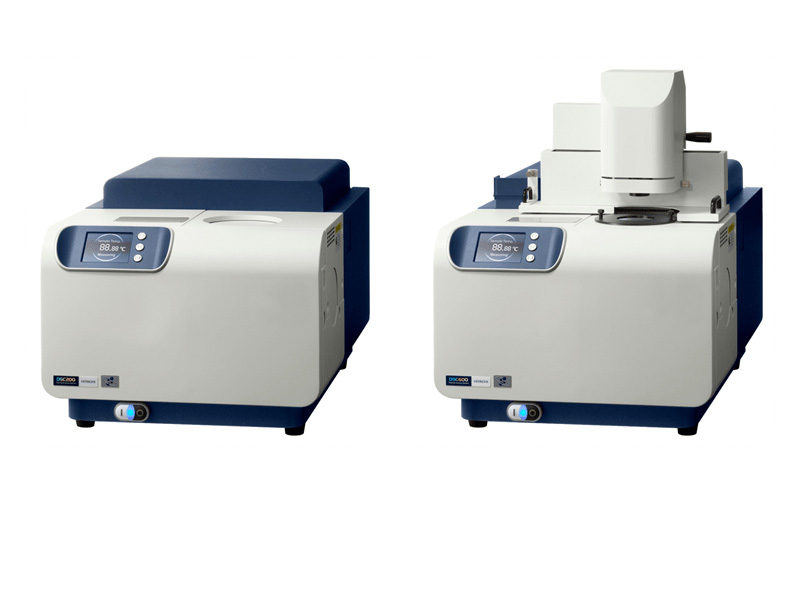

- Thermal analysis: the NEXTA DSC600, NEXTA DSC200, NEXTA STA, TMA7100, TMA7300 and DMA7100 thermal analysis range is optimized to detect and visualize the smallest reactions, while being robust, reliable and easy to use.

- Microspot XRF coatings analyzers: the FT230 alongside the FT160, FT110A and X- Strata920 measure coating thickness of single- and multi-layer coatings including alloy layers and are designed to be incorporated into quality control or process control programs, as well as research laboratories.

- Handheld analyzers: the X-MET8000 is used by thousands of businesses to deliver simple, rapid, non-destructive analysis for alloy analysis, scrap metal sorting and metal grade screening using precision XRF technology. Vulcan, powered by LIBS laser technology identifies metal alloys in just one second; hugely benefitting businesses processing high volumes of metal and making Vulcan one of the fastest analyzers in the world.

- OES metals analyzers: our OE, FOUNDRY-MASTER and PMI-MASTER range of optical emission spectroscopy analyzers are used by industries the world over for high-precision metals analysis.

- Versatile Benchtop XRF analyzers: the LAB-X5000 and X-Supreme8000 deliver highly- trusted quality assurance and process control across a diverse range of industries such as petroleum, wood treatment, cement, minerals, mining and plastics.

- Lithium-ion battery analysis: our EA8000A x-ray particle contaminant analyzer is custom designed for fast and efficient quality control in lithium-ion battery production.

- Specialist RoHS analyzers: designed for Restriction of Hazardous Substances analysis, our EA1400, EA1000AIII, EA6000VX and HM1000A analyzers are quick and easy to use, with flexibility to adapt to evolving regulation.