As a global aerospace manufacturing company which specializes in complex aerospace components for demanding applications, Polamer Precision has a strong focus on quality.

After working with SIFCO ASC on a plating application for an engine component for many years, the company brought the process in-house in a move helps Polamer to increase throughput, save costs and ensure complete ownership of the quality management process.

Aerospace components need to be able to withstand friction, high temperatures and corrosive environments while continuing to operate at optimum levels. Performance and reliability of components are paramount, while stringent regulations and market competition mean that manufacturers need to find innovative solutions to fulfil requirements.

Selective plating offers a method of electroplating localized areas without the use of an immersion tank. When compared with traditional tank plating methods, the process uses a lower volume of chemicals, offering a reduced environmental impact at a lower cost. Deposits have excellent adhesion and can be plated at rates that are 30 to 60 times faster than conventional tank plating.

“The process was previously completed by one of our network of job shops, which undertook the plating process from start to finish,” says Thomas Chapman, northeast sales manager at SIFCO ASC.

Custom Plating Workstation

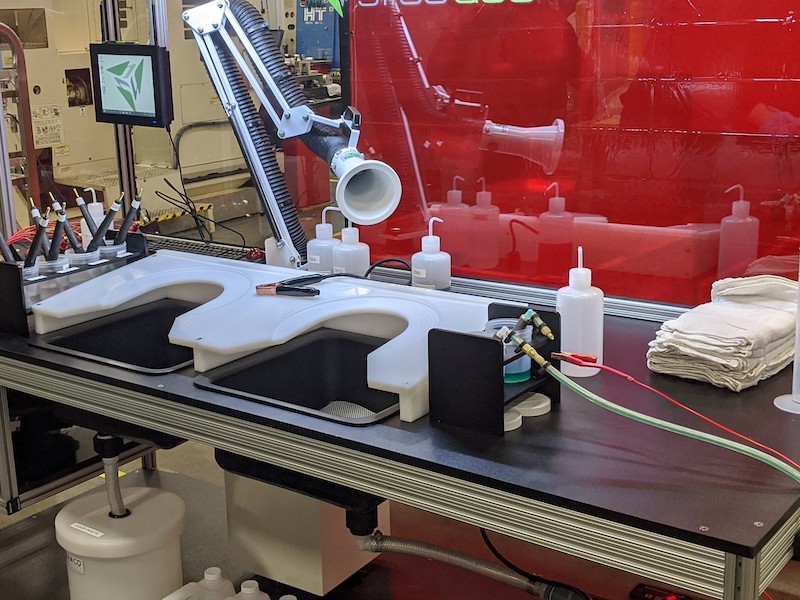

In order to increase throughput, shorten lead-times and meet increased demand, the company worked with the team at Polamer Precision to specify and install a custom workstation, enabling them to incorporate the process into their own production line.

In order to increase throughput, shorten lead-times and meet increased demand, the company worked with the team at Polamer Precision to specify and install a custom workstation, enabling them to incorporate the process into their own production line.

The workstation itself is constructed of heavy-duty, chemical resistant polypropylene and is designed with operator comfort and ease of use in mind. The work surface is designed to accommodate auxiliary equipment, including the AeroNikl Flow System which is used for this particular application.

The in-house facility also features tooling and mounting fixtures, including programmable control software for the power pack which has been designed to identify and reduce special cause variation and reduce re-work.

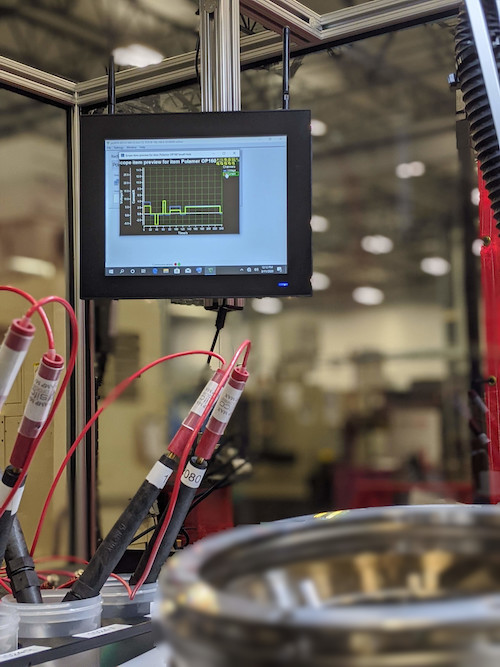

The programmable control software allows Polamer to monitor and control the process in two ways. First, it gives them the ability to passively monitor the process by manually adjusting the volts, amps and ampere hours. For tighter process control, the software also facilitates active programming of all steps, mitigating the likelihood of operator error.

In bath plating control processes, similar types of process control tracking software packages are often limited to monitoring per batch of parts. What is unique about SIFCO ASC’s process control tracking is that, unlike bath plating, it monitors plating parameters per plating surface.

Accordingly, not only can Polamer collect process control data on a part-by-part basis, they can further collect specific information on the surfaces on individual parts. Achieving this more granular level of data collection allows Polamer Precision to continually implement incremental improvements to its quality management program (QMP).

“By bringing our plating operation in-house, we’ve been able to double our output and reduce lead time by eliminating the need to ship products to an outside supplier,” says Derek Waszczuk, vice president of Operations at Polamer Precision. “Strict quality control is a key facet of our operations. The system gives us complete ownership of the manufacturing and quality control process, from raw material through to delivery, allowing us to better serve our customers.”

Visit polamer.us and sifcoasc.com.