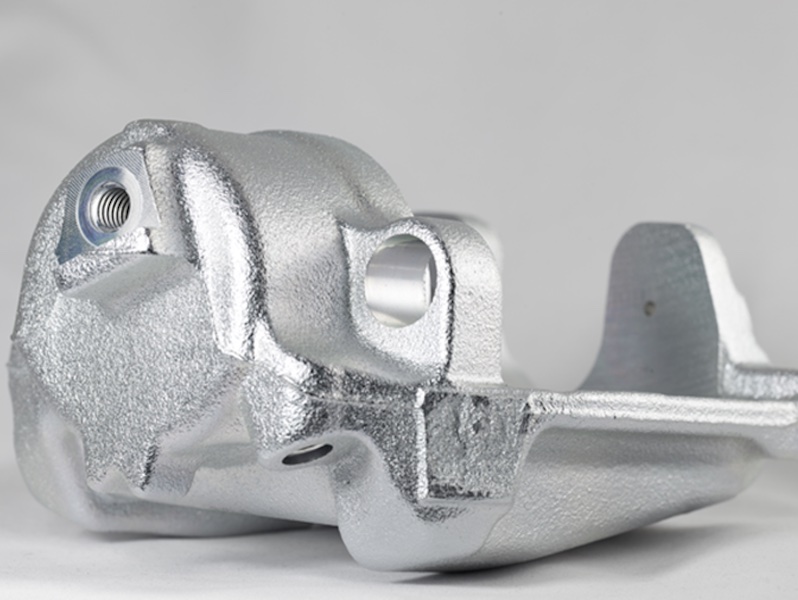

Kenlevel BF2, MacDermid Enthone’s latest acid zinc process for both rack and barrel application, offers zinc deposits with unique properties, making it ideally suited for cast iron rack plating such as brake systems, as well as for barrel applications.

In use, the additive system is low foaming, allowing fast zinc plating at high current densities (15-80 ASF) with good thickness distribution as well as excellent throwing power and gloss.

Kenlevel BF2 offers a very wide operating window and even allows applicators to choose from different brightener systems:

- Kenlevel BF2 Brightener for operation between 70°F – 100°F

- Kenlevel BF2 LT for operation below 86°F.

Kenlevel BF2 has been designed to meet REACH requirements and therefore is non-toxic and offers easy waste-treatment.

Typically, ammonia and boric acid are used to stabilize and buffer the pH in acid zinc solutions and prevent high current density burning. Despite their proven performance there can be issues with the effluent treatment, accelerated corrosive attack on plant and equipment (ammonia) or precipitation and non-REACH compliance (boric acid).

Boric acid, along with sodium tetra borates have been included in the REACH candidate list (classified as toxic for reproduction). Boric acid can be difficult to dissolve and has been replaced by a proprietary liquid additive. This liquid buffer has the added benefit of avoiding any crystallization and can be automatically replenished.

Any conventional acid zinc plating bath is easily converted to Kenlevel BF2. Simply stop adding boric acid and the old additives and start adding the Kenlevel BF2 additives! We do recommend that you first submit a sample for conversion to your local MacDermid Enthone laboratory to verify suitability.