Plating International, a leading supplier of chrome plating chemicals and equipment in the world, is revolutionizing the hard chrome plating process with its new dry IBC tote technology.

If facilities are still adding dry chromic acid from the drum by hand, they could be exceeding PEL limits and potentially exposing personnel to hazardous fumes. Plating International’s new dry IBC tote technology is the future of chrome, revolutionizing everything we know about chromic acid.

“This dustless technique greatly reduces the risks associated with hexavalent chromium – both from a safety and environmental perspective,” says John Sullivan, Plating International’s national sales director. “It’s better for your employees, better for the environment and better for your bottom line.”

Watch the Video:

Here’s a look at how it works:

- The process begins when PI receive shipments of dry chromic acid in 250-kilogram containers.

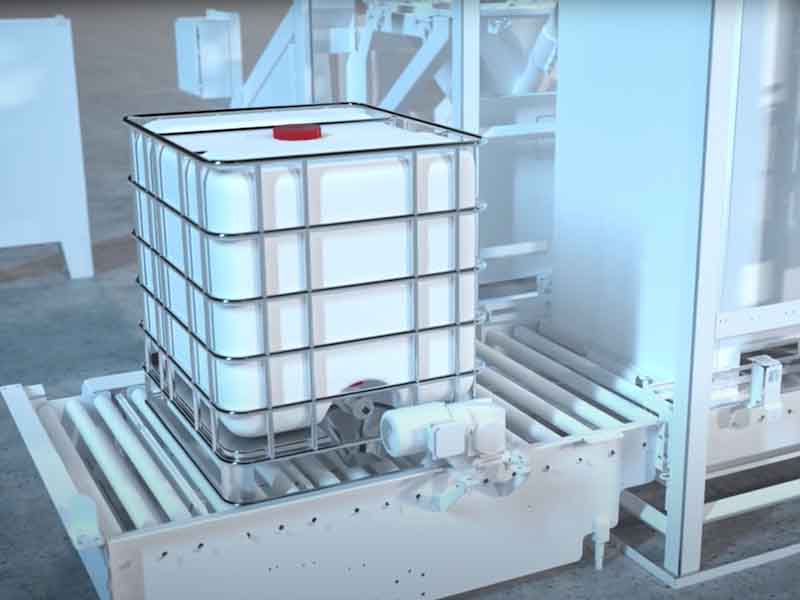

- First, PI use a proprietary dry repackaging system to transfer the chromic acid into a dry intermediate bulk container – or dry IBC tote.

- PI can package these with any weight you need for your application.

- The dry repackaging machine uses a hydraulic lift system to invert cans of chromic acid and empty them into a large loading hopper.

- The empty tote gets moved into the filling station and the filling head is lowered into the dry IBC tote.

- Then, the loading hopper uses a screw conveyor to automatically feed the desired amount of material into the dry IBC tote.

Throughout this part of the process, Plating International uses a ventilation system to ensure no employees are exposed to the hazardous chemicals. And PI uses a HEPA filter so none of the hazardous chemicals make it into the outside air. Now, the filled dry IBC tote can be used to safely manufacture liquid chromic acid.

“We can ship the tote to you like this, or use the next stage of our innovative manufacturing process to do the blending for you,” Sullivan says.

Plating International samples every tote for quality control before they ship it to customers, and their quality control rate is 100 percent. They generally manufacture each blended tote in 5 to 10 minutes.

“With this innovative technology, we can process a truckload of liquid chromic acid in under an hour,” Sullivan says. “We can also ship you dry IBC totes filled only with powdered chemicals, for you to create a finished liquid blend in your own facility.”