An in-house, gas catalytic curing oven with panels supplied by Heraeus Noblelight has allowed Doughty Engineering in Great Britain,to save £400,000 (US$547,000) a year.

Doughty is a manufacturer of rigging, suspension, and lifting equipment for film, television, theatre and concert halls. All of its products are powder coated, both for cosmetic reasons and also to ensure long life in service.

Powder coating used to be sub-contracted at an annual cost of £400,000, and some time ago Doughty decided to bring the finishing operation in-house. Consequently, they contacted Junair, the UK’s leading manufacturer of spray booths and paint finishing systems to design and install a complete powder-coating system at the Ringwood site.

It was decided that the curing section should feature a gas catalytic oven with the panels supplied by Heraeus Noblelight. The gelling of powder coatings has traditionally been carried out by convection ovens that are energy inefficient and require a large amount of floor space. They can also be expensive to run and — because of their long start-up time — they cannot be quickly shut down when there are breaks in production.

In addition, convection ovens can produce noxious gases and are not particularly suited to heating parts with sensitive substrates. Gas catalytic heating, meanwhile, can cure paints typically 50%-70% faster than conventional ovens, and offer a very short return on investment. They are also highly controllable and can be used for smaller batch sizes.

The in-house powder coating plant has proved eminently successful.

“We now have total control over our product finishing quality and have mitigated a substantial sub-contracting cost,” says Stuart Rodgers, general manager at Doughty. “Moreover, the system is easy to maintain and control.”

Gas catalytic infrared ovens save energy and time

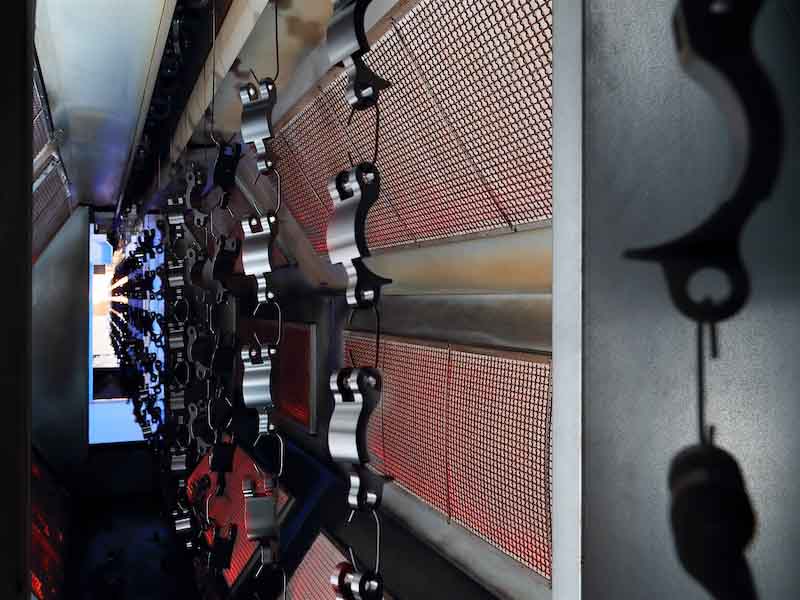

Gas catalytic ovens are available in various sizes and can operate on natural gas or propane. They are flameless, as they rely on initially heating a platinum catalyst ceramic composite heater panel. Once the catalyst has reached a given temperature, the gas switched on and flows evenly into the back of the panel, where it intermingles with the hot platinum catalyst. This initiates a chemical reaction, which produces carbon dioxide, water vapor, and infrared radiation in the long to low medium wave band of the spectrum.

Typical applications for gas catalytic ovens include the gelling of powder coatings, food drying, thermo forming, textiles drying, leather curing and curing coatings on heat-sensitive substrates, such as MDF. However, they can also be installed as booster ovens to upgrade existing production lines in a wide range of industries. Gas catalytic ovens require less space than conventional convection ovens and they can be switched on or off as required so that their booster effect can be selected at will, providing quick pre-heat with short lines.

Heraeus Noblelight offers the whole range of infrared radiation from near infrared (NIR) to mediumwave carbon infrared (CIR), conduct trials with the materials, and provide guidance in selecting the optimal emitter for every process. Visit www.heraeus-noblelight.com

Heraeus, the technology group headquartered in Hanau, Germany, is a leading international family-owned portfolio company. The company’s roots go back to a family pharmacy started in 1660. Today, the Heraeus group includes businesses in the environmental, electronics, health and industrial applications sectors. Customers benefit from innovative technologies and solutions based on broad materials expertise and technological leadership.

Heraeus Noblelight with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France and China is one of the technology- and market-leaders in the production of specialty light sources and systems. The organization develops, manufactures and markets infrared and ultraviolet emitters, systems and solutions for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques.