Atotech and Schweitzer Engineering Laboratories announced that they will partner at SEL’s manufacturing facility under construction in Idaho.

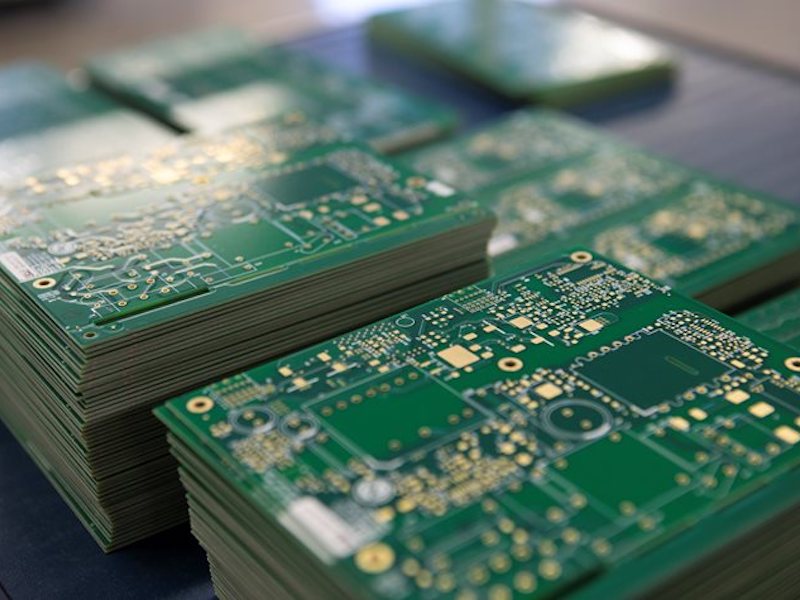

Schweitzer Engineering Laboratories is planning to build a 140,000-square-foot facility on the land it recently purchased southwest of Moscow, Idaho, on Highway 95. SEL will utilize Atotech’s innovative Uniplate equipment technology in their new 162,000 square-foot facility that will serve as home for SEL’s printed circuit board manufacturing operation. The Uniplate family of equipment is the industry standard for horizontal inline printed circuit board processes, from desmear and metallization to flash copper plating. The lines are scheduled to be commissioned in 2022.

Schweitzer Engineering Laboratories is planning to build a 140,000-square-foot facility on the land it recently purchased southwest of Moscow, Idaho, on Highway 95. SEL will utilize Atotech’s innovative Uniplate equipment technology in their new 162,000 square-foot facility that will serve as home for SEL’s printed circuit board manufacturing operation. The Uniplate family of equipment is the industry standard for horizontal inline printed circuit board processes, from desmear and metallization to flash copper plating. The lines are scheduled to be commissioned in 2022.

“As we start manufacturing our own printed circuit boards, we are committed to building the most modern, environmentally friendly, and safe PCB manufacturing facility in the United States,” says John Hendrickson, Senior Engineering Manager at SEL, who will oversee SEL’s new operation. “Atotech is a leader in their field and the right partner for us. Their horizontal plating technology offers an easy approach to automation with a focus on reducing chemical usage. This will help us meet our water recycling goals.”

Atotech’s significant investment into environmentally sound solutions benefits customers’ products and their production processes. These solutions reduce water, chemistry, energy, and waste generation, while reducing costs and meeting customer expectations for future PCB manufacturing.

Harald Ahnert“We are very excited to work with SEL to realize their needs in Idaho,” says Harald Ahnert, President of the Electronics segment at Atotech. “The equipment selected by SEL combines years of Atotech engineering leadership for horizontal production equipment. The Uniplate family brings a highly automated and environmentally sound approach to PCB manufacturing.”

Harald Ahnert“We are very excited to work with SEL to realize their needs in Idaho,” says Harald Ahnert, President of the Electronics segment at Atotech. “The equipment selected by SEL combines years of Atotech engineering leadership for horizontal production equipment. The Uniplate family brings a highly automated and environmentally sound approach to PCB manufacturing.”

SEL previously announced that local in-house production of the PCB’s used in their digital products will provide the company with more freedom to experiment and innovate. It will also increase supply-chain security and yield superior product quality.

Atotech (NYSE: ATC) is a leading specialty chemicals technology company and a market leader in advanced electroplating solutions. Atotech delivers chemistry, equipment, software, and services for innovative technology applications through an integrated systems-and-solutions approach. Atotech solutions are used in a wide variety of end-markets, including smartphones and other consumer electronics, communications infrastructure, and computing, as well as in numerous industrial and consumer applications such as automotive, heavy machinery, and household appliances.

SEL invents, designs and builds digital products and systems that protect power grids around the world. This technology prevents blackouts and enables customers to improve power system reliability, safety and cost. SEL, a 100 percent employee-owned company that is headquartered in Pullman, Washington, has manufactured products in the United States since 1984 and now serves customers in 168 countries. SEL provides unmatched technical support, customer service and a 10-year worldwide warranty.