The wife and husband team of Yoli and Chris Mara always dreamed of owning a recording studio, and having the ability to create masters was just icing on the cake.

Yoli MaraBut owning Welcome to 1979 studios in Nashville, Tennessee, also came with a byproduct: becoming electroplaters, too.

Yoli MaraBut owning Welcome to 1979 studios in Nashville, Tennessee, also came with a byproduct: becoming electroplaters, too.

Watch the video above

The 13,000 square-foot Welcome to 1979 facility has become an integral part of the recording industry in the Music City, where artists such as The Who's Pete Townshend, ZZ Top's Billy Gibbons, Jason Isbell, Blackberry Smoke, Chris Stapleton, John Prine, Alison Krauss, Keb Mo, Jamey Johnson, and many others have laid down tracks.

In-House Vinyl Mastering Capabilities

Founded in 2008, the facility later added in-house vinyl mastering capabilities that can prepare metal stampers for the artists to have their music made into records at various pressing plants, and that's where the electroplating process comes into play.

Chris Mara mans the control board at Welcome to 1979 Studios."We knew nothing about electroplating," says Yoli, who has a degree in early childhood special education and worked for several years in that field before starting the Welcome to 1979 business with Chris, who is a highly-regarded freelance recording engineer.

Chris Mara mans the control board at Welcome to 1979 Studios."We knew nothing about electroplating," says Yoli, who has a degree in early childhood special education and worked for several years in that field before starting the Welcome to 1979 business with Chris, who is a highly-regarded freelance recording engineer.

Creating vinyl records requires making a lacquer of the recording, which is when a lathe uses a cutter to etch a continuous groove into a lacquer disc to implant the sound recording.

From there, the lacquer disc gets sent to the electroplating operation in the rear of the Welcome to 1979 facilities to create a metal stamper that will eventually be sent to companies that press the record into vinyl.

At the time, there were only a few companies in the U.S. that plated the lacquers to create the metal stampers, which Chris says can be problematic once the grooves are etched into the lacquers.

Vinyl Record Sales Go Through the Roof

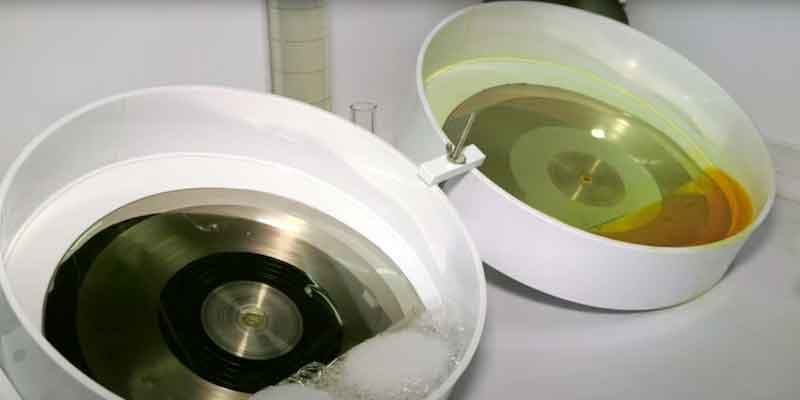

Plating machines at Welcome to 1979 Studios."The lacquer wants to start healing itself of the grooves almost immediately," he says. "That's when it becomes very important to start the plating process as soon as possible to maintain the sounds and frequencies that have been cut into the lacquer."

Plating machines at Welcome to 1979 Studios."The lacquer wants to start healing itself of the grooves almost immediately," he says. "That's when it becomes very important to start the plating process as soon as possible to maintain the sounds and frequencies that have been cut into the lacquer."

That's when Yoli and Chris came to the realization that adding electroplating to their shop would not only speed up the production of their studio's recording — and maintain the great sound — but also would fill a need among other vinyl record producers.

"We realized that if we were sending all these lacquers to basically one facility, then most everyone else was also sending them to the same facility," Yoli says. "We did see that as a problem."

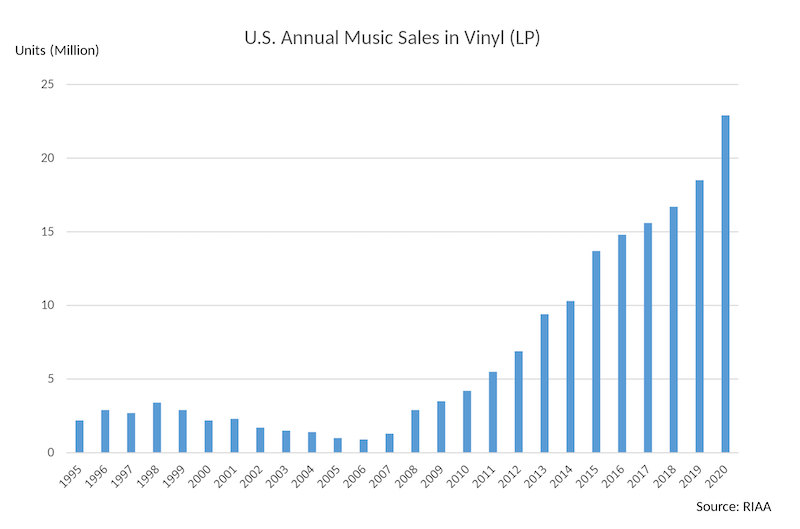

Vinyl records had become almost obsolete several years ago with the invention of compact discs in the 1980s, followed by the move to all digital music, but a resurgence over the last decade has sent production of LPs skyrocketing.

In 1993, sales of vinyl records were barely 300,000 annually in the U.S. before starting to do a slow climb to just over 1.5 million by 2000. The numbers fell again to just less than one million vinyl records sold in the U.S. in 2006, but then dramatically climbed starting in 2009 when 2.5 million were sold and has grown every year since.

And the surge continues: more than 41.7 million vinyl units were sold in 2021, almost doubling the 21.5 million sold in 2020. While more than a decade ago, vinyl accounted for less than 2% of all physical sales of music in the U.S. in 2011, it is now outselling CDs for the first time since 1991.

Finding the Right Kind of Plating Equipment

Creating a vinyl master on to a lacquer to be plated.With all of that vinyl growth came the issues that Yoli and Chris were concerned with: getting the lacquers and metal stamp ready quickly before the grooves started to heal themselves.

Creating a vinyl master on to a lacquer to be plated.With all of that vinyl growth came the issues that Yoli and Chris were concerned with: getting the lacquers and metal stamp ready quickly before the grooves started to heal themselves.

"It really became a quality issue," Yoli says. "The grooves are going to want to start to fill in, and that causes some issues with the sound, especially on the high end. It was apparent that we needed to electroplate them to metal as quickly as possible."

That also meant that Welcome to 1979 would need to find the right kind of electroplating line that was specific to the needs of finishing record stamps. Their business plan called for offering the lacquer cutting and plating process together to other studios, which meant they needed the right equipment to scale up the operation.

Yoli and Chris spent well over a year studying other plating facilities that were making lacquers and metal stamping to get a feel for what they would need to equip their shop. They initially were looking at purchasing used equipment, but they quickly saw it wouldn't meet the needs they were seeking to offer the quality of the finished product they wanted to offer.

"It was all just so old," Yoli says. "It really would have been a money pit for us."

That's when they discovered Digital Matrix in Farmingdale, New York, which still made plating lines for not only vinyl records but also CD and DVD formats. The company's VLFP 2-4-6 Cell Vinyl Lacquer High-Speed Plating System is designed for production-scale plating of multiple nickel stampers in individual modules sharing a single solution sump — or tank — to maximize efficiency and save space in a shop.

The plating shop at Welcome to 1979 Studios in Nashville.

The plating shop at Welcome to 1979 Studios in Nashville.

Proper Plating Reduces Pre-Echo, Fidelity Loss

Each module on the Digital Matrix system contains its own rotating cathode head and digitally-controlled rectifier, as well as an independent pump and filtration for each cell.

Each module on the Digital Matrix system contains its own rotating cathode head and digitally-controlled rectifier, as well as an independent pump and filtration for each cell.

In addition, Digital Matrix also provides a vinyl lacquer silvering station for applying a thin silver layer to the lacquer disk prior to nickel plating, a key process point that provides a thin metal substrate base upon which to grow the nickel layer that will form the final stampers.

"We think the most important step is the lacquer cleaning and the silvering," Chris says. "We silver every day, and we don't let lacquers sit at all. Doing it right away reduces pre-echo and fidelity loss."

After the lacquer is cleaned following the silvering, it gets moved down the line to pre-plating, where the nickel plating process is begun using a lower bath temperature and lower amperage of about 20 amps. The 20 minutes in the bath introduces the lacquer to the plating process, and Chris says it reduces additional pre-echo and noise.

The lacquer is moved to the full plating process to create what is called a "father" of the disk. It runs 50°F hotter than the pre-plate process and is run at about 185 amps.

"We use programmable rectifiers to get the exact same thickness on each of the 10 stations we run," Chris says. "In the end, it is very important for the A-side stamper and the B-side stamper to be the same weight for evenness. That makes the heat transfer the same at the pressing plant, which results in much better sound quality."

Plating the Father and Mother For Stamping

After the 111 microns of nickel as deposited on the lacquer, the "farther" is separated from the lacquer disk with ridges — which are not the same as grooves — where it then gets cleaned and put through the plating process again to create a "mother," which does have the grooves.

After the 111 microns of nickel as deposited on the lacquer, the "farther" is separated from the lacquer disk with ridges — which are not the same as grooves — where it then gets cleaned and put through the plating process again to create a "mother," which does have the grooves.

After the mother and stamper are separated following the final plating process, the stamper becomes the finished product which is then used by the pressing facilities to make the vinyl records.

Chris says the stamper is sent to an area of the Welcome to 1979 plant, where it is centered, sanded, trimmed, and formed before going to the pressing facility.

"We can customize the stamper once it's verified," he says. "We are looking for any imperfection before we center and punch a hole in it. The backside is sanded and gets trimmed based on the pressing plant specifications."

There is also a step where the Welcome to 1979 staff listens to the mother's metal grooves in a quality control room to monitor noise flow.

"If there is a pop or click, we listen to make sure it was not caused by the mother, and we can capture and send it to the artist to approve," Chris says. "If there are any issues in the sound, we can get it solved pretty quickly."

Demand Remains 'Huge' for Vinyl Pressings

U.S. vinyl record sales 1995-2020.By doing other studio lacquers and stampers, too, Yoli says Welcome to 1979's plating line is humming these days, and they have about eight employees in that department. In fact, a majority of the work in the plating department is for work from other studios and artists.

U.S. vinyl record sales 1995-2020.By doing other studio lacquers and stampers, too, Yoli says Welcome to 1979's plating line is humming these days, and they have about eight employees in that department. In fact, a majority of the work in the plating department is for work from other studios and artists.

"Things continue to go absolutely crazy with vinyl sales," she says. "Pressing plants whose turnaround time was 8 to 10 weeks is now up to 6 months. And some facilities aren't even taking on projects until 2023. The demand is huge."

While the Maras still consider themselves more recording enthusiasts than electroplaters, they have come to appreciate the intricacies of how a plating shop works and the expertise that is needed to do it correctly.

"We are still amazed at how something so tiny might go wrong and mess everything up," Yoli says. "In the beginning, it was almost like an Easter egg hunt to figure out what it was. You just have to be careful and mindful of the processes and monitor every step along the way."