Stephanie Witt is the Customer Service Manager at Advanced Plating Technologies in Milwaukee, Wisconsin, and the recipient of a National Association for Surface Finishers Award of Merit at SUR/FIN this year.

Witt has been with APT since 2020, has become engrained in the facility's operations, and is the customer advocate within the company, working with appropriate departments to ensure customer needs are met.

Stephanie WittHow did you get your start in the finishing and coating industry?

Stephanie WittHow did you get your start in the finishing and coating industry?

My current job at Advanced Plating Technologies introduced me to the finishing industry; otherwise, I have been in the manufacturing world for a long time, but in different industries.

What does your job entail?

As the Customer Service Manager, I oversee the customer service department and the interaction with existing and new customers via phone or email. It can range from just sending a PO to talking about lead times to issues a customer is having with their parts performing and would like us to help figure out what needs to be improved to make it work. It can also be sending open order reports and talking through upcoming forecasts to make sure our scheduling is on track for the customer's needs. Also, helping customers understand the basics of how plating works and the lead times associated with the plating they have chosen.

Can you walk us through a typical day for you?

There really has never been a typical day for us here at Advanced Plating. There is always a customer that needs their parts within a short amount of time, and we do everything we can to help them in a tight situation, to tracking down parts. Or we need to have a conference call to figure out details of a part they are trying to get launched, or they have an uptick in their forecast, and we need to put a plan in place to handle the increase.

What do you like best about working in the finishing and coating industry?

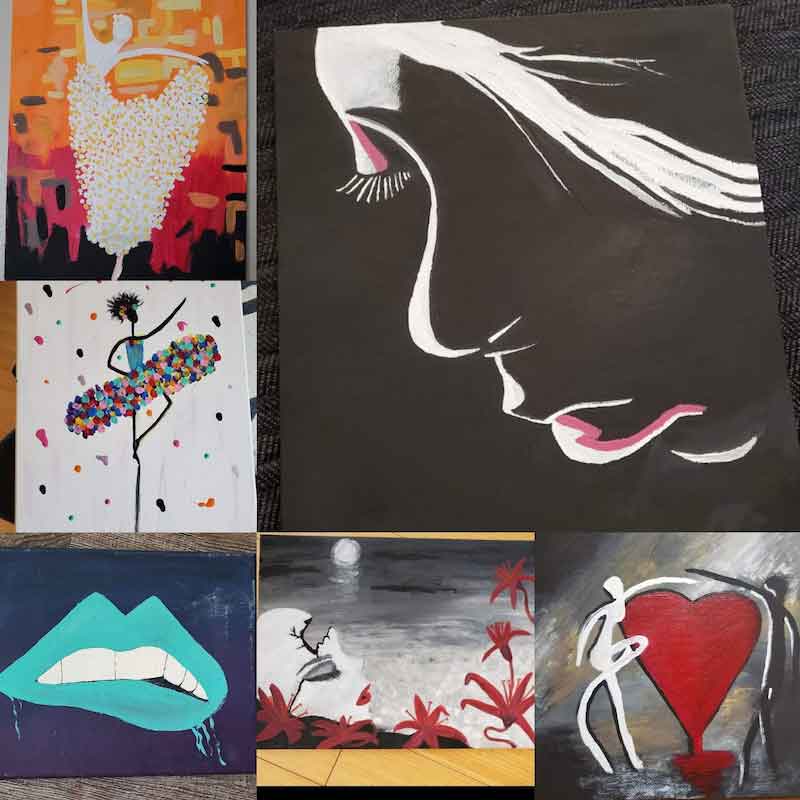

Witt likes to relax by painting.The best part about working in the plating industry is that I am learning new things every day and will for years to come. Plating is a very complex craft that is taught by on-the-job training. Getting to understand why you would use various metals to plate in a certain situation due to the end-use is remarkable to be able to be a part of. Also, being a part of NASF Wisconsin has given me the opportunity to be exposed to other plating manufacturers and vendors in this industry, and it is truly a great community to be a part of. Everyone works together in this industry to help inform each other about new laws that are happening that can affect each business, and there is a sense of comradery that is great to be a part of.

Witt likes to relax by painting.The best part about working in the plating industry is that I am learning new things every day and will for years to come. Plating is a very complex craft that is taught by on-the-job training. Getting to understand why you would use various metals to plate in a certain situation due to the end-use is remarkable to be able to be a part of. Also, being a part of NASF Wisconsin has given me the opportunity to be exposed to other plating manufacturers and vendors in this industry, and it is truly a great community to be a part of. Everyone works together in this industry to help inform each other about new laws that are happening that can affect each business, and there is a sense of comradery that is great to be a part of.

What preconceived notions about the finishing and coating industry have changed since you started working in it?

The famous line that you just dip the parts to plate them, and it's done. Even from day one, seeing the different plating lines set up and the different chemistry that is used during the plating process, such as pre-cleaners, vapor degreasers, and acid pickles that prep parts before plating the metals. Even the different quality-related testing methods need to happen for parts to pass the inspection process. It is way more complex to plate parts to a high-quality standard that there is a lot that goes into it.

Can you describe a particular project you have been involved in that made you most proud?

Throughout my career, I have helped implement several different improvement projects, from a new production system to a complaint tracking process. I would say since I have been here at APT developing the customer service department to be proactive with customers and giving them step-by-step updates and open order reports to keep open communication. The positive feedback we have received from existing customers is more than enough to prove that we have improved our process and the way we communicate with our customers for the better and only look to keep on improving as we move forward.

Why would you recommend to a friend a career in the finishing and coating industry?

Within the plating industry, you are always learning, and no one day is the same as the previous one. It keeps you on your toes and is a very engaging field to work in.

What is the toughest part of your job?

The toughest part is when the unexpected happens and the chemistry in a take plate out, and you have parts lined up out the door to be plated in that tank, or when you plate a part that shouldn't be a difficulty for it just won't plate right. And you must break each step down, investigate the part and find the problem and fix it. This can also be the fun challenging part of the job, where you just need to get things done and solve problems as they come.

The toughest part is when the unexpected happens and the chemistry in a take plate out, and you have parts lined up out the door to be plated in that tank, or when you plate a part that shouldn't be a difficulty for it just won't plate right. And you must break each step down, investigate the part and find the problem and fix it. This can also be the fun challenging part of the job, where you just need to get things done and solve problems as they come.

How do you describe what you do in your job to family and friends and the importance of it?

When I say that I work at a plating shop, they give me a little confused look, and I just simply tell them that we put metal onto parts using electrical current. We plate parts ranging from shells/projectiles to pieces that go into computers on motherboards to aerospace components. And I lead the customer service department within my company.

Are you involved in any industry associations or trade groups?

I am a board member of the NASF Wisconsin Chapter as its secretary.

What type of college, school, or training have you had?

I graduated from the University of Wisconsin in Platteville with a bachelor's degree in communications and an emphasis in public relations. I attended a Dale Carnegie Course for Effective Communication and Human Relations to further develop my communication skills when dealing with customer service.

What motivates you to work hard at your job?

I have always been motivated by coming up with ideas or implementations, and once they are in place, employees use the material, documents, procedure, etc., and it is a useful tool for the company. Knowing I have made things easier or helped a team member in a way to do their job better or more efficiently is enough for me.

Tell us about your outside hobbies and interests.

I was involved in sand or court volleyball, but since I have had kids, their sports and extracurricular activities have kind of taken over, as most parents would say. We all are now active and like to work out, be outside doing something, go boating or to the beach. My relaxing hobby is painting.

What three things do you think of the most each workday?

- I am always looking at my calendar for what is in store for that day and what has been added to the schedule.

- Checking emails constantly, the way customers communicate these days is mostly through email

- How many things can I get done at the same time? Truly, you must be good at multi-tasking and working on an order at the same time, taking a call from a completely different customer and helping them answer any questions they may have, and then getting back to my first order.