The stripping of electrodeposited and flame-sprayed coatings is a necessary part of surface finishing.

Frank AltmayerStripping may be required to allow for the re-plating of a part rejected due to defective finishing or as part of rework processes such as those commonly conducted by airline/aerospace facilities.

Frank AltmayerStripping may be required to allow for the re-plating of a part rejected due to defective finishing or as part of rework processes such as those commonly conducted by airline/aerospace facilities.

This paper discusses stripping methods and operational considerations in their use.

Stripping Metallic Coatings in Aerospace Applications

The stripping of electrodeposited and flame-sprayed coatings — along with organic coatings such as paints and lacquers — is a necessary part of surface finishing. Stripping may be required to allow for the re-plating of a part rejected due to defective finishing or as part of rework processes such as those commonly conducted by airline/aerospace facilities.

Airline/aerospace facilities conduct stripping of a number of metallic/semi-metallic coatings. Some of those more commonly encountered are:

- Cadmium / cadmium alloy

- Copper

- Nickel / electroless nickel

- Chromium

- HVOF spray

- Pack diffusion (high temperature) coatings

- PVD deposited coatings

Stripping these coatings facilitates the inspection of the parts, allows for refinishing with a newer, more effective coating, or allows the application of a replacement coating.

Stripping Theory

The basic chemical reaction conducted when stripping a metal is that of oxidation, i.e., the metal is converted from the zero valent states to a higher valent (ionic) state. Essentially, this is the reverse of the deposition process.

To allow such a chemical reaction to proceed, we have basically two choices:

- React the metallic coating(s) with a solution that is powerful enough to oxidize the metal (dissolve it).

- React the metallic coating(s) with a combination of electrical power and a chemical solution that will keep the metallic coating in either the dissolved state or will allow the dissolved metal to crystallize out and be removed from the process as a salt or sludge.

Chemical-Immersion Stripping

Over the 150+ years that the electroplating industry has been active, a number of stripping solutions have been developed. Some of these are popularly employed “generic” formulations that can be obtained from almost any textbook and from articles published in surface finishing journals. Of course, there are also commercial stripping products that may be safer, more effective, and more economical and may allow for the generation of recyclable forms of the stripped metals.

In the airline/aerospace industry, equipment manufacturers have approved lists of generic and proprietary stripping solutions.

Chemical immersion stripping is preferred over other methods because the process can strip complicated shapes (stripping occurs wherever the solution touches the surface). Chemical immersion stripping also does not require rectifiers, bus bars, racking/rack design, and the paying of an electricity bill. However, chemical strippers tend to slow down in stripping rate as the solution is used and builds up in metal content. Immersion strippers typically cost more to use than electrolytic.

In the airline/aerospace industry, equipment manufacturers have approved lists of generic and proprietary stripping solutions, and only these can be employed under the specified conditions after referring to the latest revision of the manufacturer’s specification(s). Care should be taken not to exceed the maximum immersion times prescribed by the specifications, as etching, pitting, or roughening of the basis metal may result from exceeding such immersion times.

Electrochemical Stripping

Electrochemical stripping is employed when immersion solutions are ineffective, unavailable, or too difficult to use (too slow, too uneconomical, or too aggressive on the basis of metal). The part is connected to the positive terminal of the rectifier (anode bus bar on the tank). The counter electrodes are typically steel or stainless steel. As in electroplating, careful control over the voltage (and therefore the current density) on the part is critical to success. Too high a voltage during electro-stripping can cause localized pitting of the basis metal (usually at the high current density areas).

Electrochemical stripping typically removes metal faster at the high current density surfaces and may leave traces of the coating to be stripped in recesses and other low current density areas. Electrolytic strippers are less expensive and provide more steady rates of stripping than immersion types. Electrolytic strippers are more prone to pitting problems than immersion types. Airline/aerospace specifications typically prescribe the current density range or maximum voltage to be applied during electrochemical stripping.

Stripping by Mechanical Means

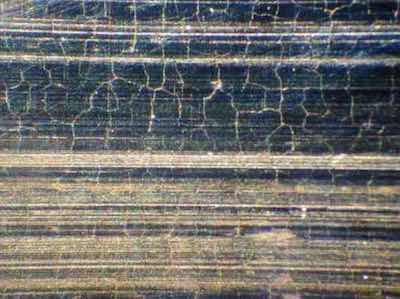

"Chicken cracks" caused by excessive grinding pressure and/or insufficient lubrication.It is important that we point out that mechanical means can be and often are also utilized to remove organic and inorganic coatings, especially when the part shape makes the application of abrasive methods practical. Mechanical finishing may also be employed in addition to chemical stripping to produce a more uniform surface finish on the stripped part and/or to remove smut and other residues that may be left behind by chemical methods.

"Chicken cracks" caused by excessive grinding pressure and/or insufficient lubrication.It is important that we point out that mechanical means can be and often are also utilized to remove organic and inorganic coatings, especially when the part shape makes the application of abrasive methods practical. Mechanical finishing may also be employed in addition to chemical stripping to produce a more uniform surface finish on the stripped part and/or to remove smut and other residues that may be left behind by chemical methods.

Blasting, machining, grinding, and vibratory finishing are the most commonly employed mechanical methods of stripping or treating parts after chemical or electrochemical stripping. Machining and grinding are commonly employed methods of stripping or finishing parts with simple geometries, such as shafts and cylinders, while blasting is employed on more complicated part shapes.

In the airline/aerospace industry, equipment manufacturers provide specifications that describe the approved methods of mechanical stripping/finishing. These must be carefully followed since machining and grinding in an uncontrolled manner can cause surface defects before and after re-plating. As an example, Boeing has reported that grinding the stripped surface of a part by using too much pressure and not enough lubrication can cause “chicken cracks” to appear in the hard chromium deposit (Fig. 1).

Immersion and electrochemical stripping solutions typically contain highly aggressive ingredients (cyanide, strong caustics, or strong acids) that pose a serious health risk. Numerous strippers are commercial products that may be relatively benign based on the MSDS, but these products are designed to be blended with cyanide or other dangerous ingredients to yield the final stripping solution.

The operator must consult both the MSDS and the Technical Data Sheet for any commercial stripping product to gain sufficient information to safely handle the stripping solution.

Some ingredients in stripping solutions may become especially hazardous if accidentally mixed with an incompatible material (e.g., ammonium nitrate plus diesel fuel becomes a bomb.).

The operator must consult both the MSDS and the Technical Data Sheet for any commercial stripping product to gain sufficient information to safely handle the stripping solution. Because a commercial supplier can provide technical assistance, it is recommended that commercially available products be used instead of generic solutions whenever possible.

Hydrogen Embrittlement Issues

Parts requiring stripping may be sensitive to hydrogen embrittlement. These include high-strength steels (Rockwell Rc35+), high-strength stainless steels (especially 15-5, 17-4PH), and even some beryllium-copper alloys. Therefore, some stripping solutions and stripping methods must not be used on parts made with hydrogen-sensitive alloys.

With a few exceptions, steel parts that are heat treated above 180,000 psi (threaded steel heat treated above 160,000 psi) tensile strength and stainless steel parts heat treated to >200,000 psi UTS should be stress-relief baked before chemical stripping operations are conducted.

According to Boeing BAC 5771 (Stripping Inorganic Finishes):1

- Precipitation-hardened corrosion-resistant steel parts shall be stress relieved at 700 ± 25°F for 3 hours.

- Coil springs shall not be stress relieved.

- Stress relieves 50°F below the minimum tempering or aging temperature established for the specific alloy and strength level except as required below. Stress relieving time shall be that established for tempering or aging per BAC5617 or BAC 5619.

- Parts that are tempered above 850°F are allowed to be stress relieved at 800 ± 25°F to reduce part relaxation and dimensional change. Stress relieving of parts that have been shot peened shall be performed at 375 ± 25°F for 3 hours minimum. Stress relieving of parts that are cadmium, tin, zinc, or lead plated shall be performed at 375 ± 25°F for 3 hours minimum. Stress relieving of nitrided parts shall be performed at 375 ± 25°F for 3 hours minimum.

Also, according to BAC 5771, the following baking procedures should be employed after stripping and before re-plating (Table 1):

Table 1 - Recommended post-strip stress-relief baking procedures per BAC 5771.

| Type of part | Heat treatment | Temp. (°F) | Min. hr bake |

| Threaded steel parts (except carburized) | Over 160 ksi | 375 ± 25 | 3 |

| 440 A B and C steel parts | Heat treated | 275 ± 25 | 5-8 |

| Other steel parts | Carburized | 275 ± 25 | 5-8 |

| Other steel parts | >180 ksi or nitride | 375 ± 25 | 3 |

Stress relief baking after stripping and before plating should start as soon as possible, but in no case longer than 24 hours after stripping is completed.

Certain solutions should not be used on hydrogen-sensitive substrates. Some of the non-commercial stripping solutions that should not be used are based upon:

- Hydrochloric acid

- Sulfuric acid

- Acetic acid + hydrogen peroxide

- Chromic acid + sulfuric acid

- Nitric acid

Preparing a Stripping Solution

Unless otherwise directed by the Technical Datasheet, the following steps should be taken to produce the stripping solution:

- Fill the tank approximately 1/3 full with water.

- Add solid chemicals (if any) in small portions to a water-filled day mixing tank or a (suitable) plastic 55-gallon drum equipped with a mixer. Mix until all solids are dissolved, and then pump over to the stripping tank. Some solids may dissolve more effectively if warm water is employed.

- Add liquids slowly to the stripping tank with mixing and allow the solution to cool to normal temperature if the liquid causes the temperature to rise. Add acids (if any) first, then add any additional liquids.

- Fill the tank to 2/3 operating level with water and mix thoroughly. Bring the solution to operating temperature. Have the solution analyzed to verify the correct concentration of critical ingredients (the concentrations will, of course, be higher than desired). Do not fill the tank all the way at this point. The lab may dictate removing the solution to reach the right concentration level if you do.

- Make appropriate adjustments to the solution as dictated by the laboratory analysis, keeping in mind that the concentrations are higher than the final solution due to the lower water content.

- Once the analysis shows that the addition of the last amount of water will yield the right concentration and ratios of ingredients, add the last amount of required water.

Operational Issues

Prior to stripping, be sure that the part(s) have been stress relieved (if required) and that the surface condition (roughness, color, cleanliness) of the part is as uniform as possible. All lubricants should have been removed from the surface prior to stripping by use of a vapor degreaser or aqueous-based cleaning system. Do not count on the stripping solution to clean the part. The presence of traces of oils, grease, or blasting grit may result in localized etching or pitting of the substrate.

Depending on the stripping solution employed, operational conditions such as temperature, maximum immersion time, pH, current density, voltage, the maximum concentration of stripped metal, and agitation level may be important variables to control. Stripping processes that operate at elevated temperatures need to be controlled to within ± 5°F. Tanks containing stripping solutions that operate at elevated temperatures need to be equipped with a method of agitating the solution to prevent temperature stratification, which can cause varying stripping rates. Boeing specifies a maximum temperature gradient of 10 degrees between the hottest and coldest part of a stripping solution.

Always fully immerse the part. Stripping solutions are more aggressive at the air-water interface. Partially immersed parts will tend to suffer severe etching at this juncture.

It is a good operational practice to remove and visually inspect a part after it has been immersed in a stripping solution for about 10-20% of the anticipated stripping time. After a quick spray rinse, look for uniform surface coloration and verify the absence of pitting.

Keep track of the immersion time in the stripper. Aluminum parts are particularly prone to chemical attack of the basis metal when stripping chem film or anodic coatings.

Check the part frequently (every five minutes for anodic coatings) and remove it when the base metal is visible. Loose or partially removed coating may be removed by following mechanical means or a simple scrubbing with an abrasive pad.

Always fully immerse the part. Stripping solutions are more aggressive at the air-water interface. Partially immersed parts will tend to suffer severe etching at this juncture.

In many cases, the stripping process will leave smut on the substrate. This may be removed by using an approved de-smutting solution or by physical means, such as blasting or hand scrubbing.

Stop using the stripping solution (and consider replacing it) when:

- Anon-removable smut is formed, or metal is deposited on the surface of the part.

- The solution temperature or composition is outside the control limits (especially the maximum dissolved metal content).

- The stripping solution surface has oily residue floating on the surface.

- Parts are pitted or excessively etched.

- The solution takes too long to strip or has produced a significant amount of sludge.

Basis Metal Attack

Parts that are assembled from different metals may need masking to prevent the chemical attack of the less corrosion-resistant basis metal.

Certain stripping solutions are used despite the fact that the solution will attack the base metal after the coating is stripped off. These solutions must be carefully monitored on a far more frequent basis than solutions known not to attack the basis metal. An example is a solution of nitric-fluoride which may be employed to remove flame-sprayed coatings on aluminum substrates. This solution has a high etching rate on all aluminum alloys.

Some metal alloys (especially high carbon steels and PH stainless steels) will tend to have impurities and alloying elements segregated at the grain boundaries. This makes such alloys more prone to grain boundary attack, resulting in pitting and/or preferential attack at the grain boundaries. Stripping solutions should not cause an intergranular attack in excess of .0002” or end grain pitting greater than .001” (BAC 5771). Immersion stripping solutions are less prone to grain boundary attack than electrolytic solutions.

Many generic and commercial stripping solution formulations (both acidic and alkaline) contain at least one nitro-organic compound. Common examples are nitrobenzene sulfonic acid, nitrochlorobenzene and nitrobenzaldehyde. These compounds undergo chemical reduction as the metallic coating is oxidized. Many metallic coatings act as depolarizers for the reduction reaction of these compounds, and the dissolution of such metals is therefore enhanced. Fortunately, iron is not a depolarizer for these compounds and is, therefore, relatively free from attack.

However, in alkaline stripping solutions, iron can be attacked — resulting in pitting and localized etching — if the free alkalinity and complexing agent in the solution are not under good control.

Plating Stripped Parts

Since chemical stripping is an oxidation process, the surface of a stripped part is typically in a passive state. Before plating, the parts must be thoroughly cleaned (if stored prior to plating) and reactivated with a suitable acid or electro-acid. Hydrogen-sensitive parts will require hydrogen relief baking after plating, even if baked prior to plating.

Reference

- Boeing Specification BAC 5771 Stripping Inorganic Finishes, Revision J.

Frank Altmayer is a Master Surface Finisher and an AESF Fellow who is the technical education director of the AESF Foundation and NASF. He owned Scientific Control Laboratories from 1986 to 2007 and has over 50 years of experience in metal finishing. He was the recipient of the AESF Past Presidents Award, NAMF Award of Special Recognition, AESF Leadership Award, AESF Fellowship Award, Chicago Branch AESF Geldzahler Service Award, and NASF Award of Special Recognition.