Most shops would like to be armed with some basic information as to what operational conditions in producing castings are related to defects that may cause plating-related problems.

Frank AltmayerOne company told me they plate mostly onto aluminum die castings, and a small part of their work is made of cast iron. They said they knew little about the relationship between casting quality and plating quality.

Frank AltmayerOne company told me they plate mostly onto aluminum die castings, and a small part of their work is made of cast iron. They said they knew little about the relationship between casting quality and plating quality.

With some assistance from the “Metals Handbook” (American Society for Metals or ASM International), here is a primer for you.

Casting

Pouring molten metal into any type of mold will produce a casting of some type. Most metals begin their existence this way. If an object is permitted to retain its as-cast shape and is altered only by machining or other surface finishing operations, the object is called a casting. In addition to mold/sand casting, other techniques include die casting, centrifugal casting, and vacuum casting. Casting requirements for producing quality castings include proper chemical composition, grain size, density, cleanliness, and mechanical properties that must be met. To accomplish mold-casting, there are a multitude of design and processing steps that must be administered in a reproducible manner. As an example, cast iron parts are typically produced using mold/sand casting methods. These castings contain high carbon (2% to 4%) and silicon (1% to 3%), the balance being iron. High-carbon irons and steels tend to form tough-to-remove smuts during cleaning. Aggressive cleaning and pickling can dissolve away the iron, baring carbon stringers that can produce nodules or blisters.

A brake caliper electroplated in a weak acidic electrolyte followed by passivation in a blue trivalent passivate and sealant.All castings may evidence a high level of porosity at or near the surface. Casting porosity levels can be reduced at the source by proper control over the process.

Alloys containing silicon need to be pickled in sulfuric-hydrofluoric or sulfuricbifluoride acid mixtures.

Even the best casting will contain some pores near the surface. Excessive polishing may cut through the skin on a casting and travel down to the porous layer. Plating over these pores or fissures usually results in blistering and/or peeling, as surface pores can trap chemicals in the cleaning and acid pickling operations and can be held in place through the rinsing operations by a phenomenon called “capillary action.” After plating, chemical compounds trapped in these pores can slowly leak out through cracks in the plated deposit, causing staining, or the trapped chemicals can push on the plated metal layers, creating a blister.

Because of the high level of carbon content, cast iron alloys have a low hydrogen overvoltage potential in some plating solutions (cyanide zinc, for example). This hydrogen overvoltage potential is so low that only hydrogen is produced when voltage is applied to the part. Pickling cast iron should be conducted only in inhibited acid to avoid cracking and minimize smut formation. Keep pickling time to a minimum. Alloys containing silicon need to be pickled in sulfuric-hydrofluoric or sulfuricbifluoride acid mixtures.

Die Casting

Die casting is the primary method of producing complex shapes from aluminum, zinc, and sometimes copper and other metals. Aluminum and zinc die castings are commonly electroplated for appearance and corrosion protection purposes.

Die casting is the primary method of producing complex shapes from aluminum, zinc, and sometimes copper and other metals. Aluminum and zinc die castings are commonly electroplated for appearance and corrosion protection purposes.

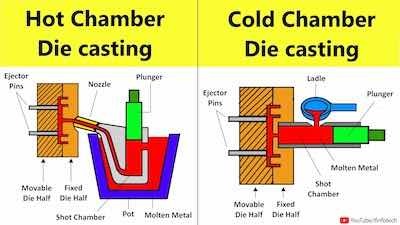

Figure 3 shows, in schematic form, a horizontal, cold chamber die-casting process, which is commonly used for producing aluminum castings. Zinc die castings are produced using a hot chamber casting machine (molten zinc is drawn into the chamber directly from the pot of molten metal), but the basic process is the same.

Step 1:

The molten aluminum is poured into the shot chamber. Just the right amount of metal must be poured to avoid casting flaws.

Step 2:

The plunger rod closes off the pouring hole and then compresses the metal into the die. The die is designed to deliver molten metal smoothly throughout the cavity and eliminate air from the cavity as the molten metal enters. If this is not done well, porosity, cold shuts (metal that has not completely melted to itself), and flow lines will be produced in the final product. At this point, the molten metal is allowed to solidify inside the cavity.

Step 3

After the solidification dwell time, the ejector half of the die opens, and the plunger pushes on the solidified casting, releasing the part and attached “biscuit” of un-cast metal from the shot chamber from the die cavity. After the application of the mold release compound, the die halves close, and the process can begin to produce the next part.

Casting Flaws

A brake caliper electroplated in a weak acidic electrolyte followed by passivation in a blue trivalent passivate and sealant.Any casting flaws that affect the surface of the casting require that the polishing buffing operation remove enough metal to eliminate the flaw (if possible). A normal casting has a relatively dense metal skin but is porous underneath this skin. Aggressive polishing (called “cutting”) to remove surface flaws often cuts through the dense metal layer and reveals surface pores. These pores are often not visible due to metal smears produced by the polishing/buffing operation. However, the cleaning and acid dipping in the plating line removes enough metal to open up these defects. Chemicals that are drawn into surface pores and fissures produce residues that are bridged by the plating. Temperature changes cause shear forces at these defective sites, producing adhesion failures that may be blisters or peeling of the plated deposit. Some plating operations utilize a heavy deposit of acid copper followed by buffing in an attempt to remove surface flaws. Any surface flaws that are large enough to see with the unaided eye are too large to “cure” this way.

A brake caliper electroplated in a weak acidic electrolyte followed by passivation in a blue trivalent passivate and sealant.Any casting flaws that affect the surface of the casting require that the polishing buffing operation remove enough metal to eliminate the flaw (if possible). A normal casting has a relatively dense metal skin but is porous underneath this skin. Aggressive polishing (called “cutting”) to remove surface flaws often cuts through the dense metal layer and reveals surface pores. These pores are often not visible due to metal smears produced by the polishing/buffing operation. However, the cleaning and acid dipping in the plating line removes enough metal to open up these defects. Chemicals that are drawn into surface pores and fissures produce residues that are bridged by the plating. Temperature changes cause shear forces at these defective sites, producing adhesion failures that may be blisters or peeling of the plated deposit. Some plating operations utilize a heavy deposit of acid copper followed by buffing in an attempt to remove surface flaws. Any surface flaws that are large enough to see with the unaided eye are too large to “cure” this way.

Common die-casting flaws include cold shuts (subsurface fissures), surface porosity, metal flow lines, and heat checks (ridges in the casting produced by minor cracks around sharp corners). These flaws are related to the following casting conditions.

Gating System Design

The gating system is a primary factor in the production of acceptable die castings. It includes runners, gate inlets, gates, vents, and overflows, which are designed to deliver a smooth, uniform flow of molten metal to the die cavity and allow for the air inside to escape efficiently. The optimum fill rate of the die cavity depends on the thickness of the casting, type of metal cast, metal temperature, die temperature, and the

geometry of the casting. Flow lines may be produced by the poor condition of the die cavity, employing too much time between casting cycles, or because gates are improperly located.

Die Temperature

A brake caliper coated directly using a ZnNi electrolyte passivated with transparent trivalent passivate.The correct die temperature for a specific casting is determined by the die section thicknesses and by the type of finish required. The dynamic temperature that the die reaches is a product of the temperature of the casting metal, the size of the shot, the time between cycles, die cavity geometry, and level of die cooling.

A brake caliper coated directly using a ZnNi electrolyte passivated with transparent trivalent passivate.The correct die temperature for a specific casting is determined by the die section thicknesses and by the type of finish required. The dynamic temperature that the die reaches is a product of the temperature of the casting metal, the size of the shot, the time between cycles, die cavity geometry, and level of die cooling.

Die temperature is controlled by the incorporation of heating and cooling devices. Temperature should be maintained within ±5°C. When the die temperature is too low, the overflows fail to fill, and the castings may have excessive internal porosity, cold shuts, and flow marks.

When the die temperature is too high, heat checking (small surface fissures in the surface of the die) may occur. Heat checks produce ridges in the casting, which require aggressive polishing to remove, resulting in surface pores. Higher than necessary temperatures also shorten the number of shots that can be produced from a given die and can cause poor product ejection (hang-ups).

A raised fin pattern (heat checks) on the casting near the gate indicates the die surface is failing due to thermal fatigue. The life of the die can be prolonged by polishing at the first sign of failure. Thermal fatigue can be delayed by suitable preheating of the die.

Shrinkage caused by hot spots may occur when sufficient cooling cannot be provided, or cores cannot be built into the die, particularly in heavy sections.

Excessive Die Wear

Excessive die wear can be the result of casting high silicon content alloys, high die temperature, high temperature of the molten metal, and the presence of sharp edges or corners in the die design. Worn dies produce castings with poor surface conditions, requiring more polishing.

Mold Release Compounds

Mold release agents prevent a casting from “sticking” to the die. They also assist metal to flow into narrow die cavities. Mold release agents must be chosen for the given operation, as no one product works well for all die-casting operations.

When the molten metal interacts with the release agent, most of it is thermally destroyed (carbonized), producing a solid residue that acts to lubricate the process. Typically, five to six shots of metal can be produced before the release agent must be reapplied, but if the release agent has a carbonizing temperature that is too low, it is essentially used up after each shot and may produce gases that yield porosity.

Mold-release compounds incorporating silicones are notorious for causing adhesion problems in electroplating. These should never be used for casting parts destined to be plated.

Frank Altmayer is a Master Surface Finisher and an AESF Fellow who is the technical education director of the AESF Foundation and NASF. He owned Scientific Control Laboratories from 1986 to 2007 and has over 50 years of experience in metal finishing. He was the recipient of the AESF Past Presidents Award, NAMF Award of Special Recognition, AESF Leadership Award, AESF Fellowship Award, Chicago Branch AESF Geldzahler Service Award, and NASF Award of Special Recognition.