Take a few short steps at Hohman Plating, and you will find the remnants of a 106-year-old finishing operation that is transforming into one of the world's newest and most modern facilities.

Brad KremerThe Dayton, Ohio, electroplater, founded in 1918, is ready to christen a 26,000-square-foot addition to its existing 100,000-square-foot plant. When numerous new lines are established in the new addition in June and processes are moved over, the $12 million project will allow Hohman to refurbish the current building and add even more operations.

Brad KremerThe Dayton, Ohio, electroplater, founded in 1918, is ready to christen a 26,000-square-foot addition to its existing 100,000-square-foot plant. When numerous new lines are established in the new addition in June and processes are moved over, the $12 million project will allow Hohman to refurbish the current building and add even more operations.

“What excites me most about all of this,” says Brad Kremer, General Manager of Hohman Plating since 2015, “Is that by providing more space and better tools, we are allowing our employees to serve our customers even better and shine even brighter.”

15 Lines, 50+ Processes, 1,000+ Specifications

Hohman is ready to christen a 26,000-square-foot addition to its existing 100,000-square-foot plant. And shine Hohman Plating does, with its current 15 finishing lines, more than 50 total processes, and over 1,000 specifications they meet in the aerospace, defense, nuclear, automotive, medical, and construction industries.

Hohman is ready to christen a 26,000-square-foot addition to its existing 100,000-square-foot plant. And shine Hohman Plating does, with its current 15 finishing lines, more than 50 total processes, and over 1,000 specifications they meet in the aerospace, defense, nuclear, automotive, medical, and construction industries.

The company is one of the top-tiered finishing operations in North America, working with some of the world's largest and most distinguished OEMs and manufacturers. It offers a plethora of processes, including anodizing, black oxide, cadmium, chem film, copper, decorative chrome, dry film lubricants, electroless nickel, hard chrome, nickel, passivation, phosphate, precious metals, primer, PVD coatings, tin, and zinc finishes.

Its more than 170 employees work three shifts around the clock to service customers and provide unique processes that few other shops can touch.

The goal of Hohman Plating's recent spate of expansions has been to provide more opportunities to double its current annual sales of $36 million.

“As our sales and ambitions grew, the need for expansion became much more evident,” Kremer says. “We knew in 2015 that we were going to expand, and that's when we started acquiring properties on the next city block.”

If that seems like a daunting task for the management team, they have done it before: when Kremer came to Hohman in 2015, he set out a path to expand operations and become more efficient, and they were able to double sales in eight years from $18 million annually.

“We worked with our owners and implemented a little bit of Lean practices here and there,” Kremer says. And now we see the need for expansion so we can continue to service our current customers and new customers who want to work with us.”

New Owners Bring New Opportunities

With the new lines, Hohman wants to expand their zinc-nickel processes, aerospace primer applications, and physical vapor deposition work.Until 2022, Hohman Plating was owned by William Miller and Todd Boyer, two of the industry’s most respected finishing experts. In 2022, they sold the company to Novaria Group in Texas, a manufacturer of specialty hardware, components, and coatings for the aerospace and defense industries.

With the new lines, Hohman wants to expand their zinc-nickel processes, aerospace primer applications, and physical vapor deposition work.Until 2022, Hohman Plating was owned by William Miller and Todd Boyer, two of the industry’s most respected finishing experts. In 2022, they sold the company to Novaria Group in Texas, a manufacturer of specialty hardware, components, and coatings for the aerospace and defense industries.

The acquisition marked the fifth transaction in the past 12 months as Novaria sought to continue growing its robust family of aerospace and defense capabilities, which includes Advanced Coating in Rancho Cucamonga, California — specializing in Parylene conformal coating of high-risk substrates and delicate components — and Weatherford Aerospace in Texas, which performs chemical processing, surface treatments and specialized forming of materials for the aerospace industry.

“Bill had been at Hohman for over 50 years, and Todd had been here for over 37 years, and they both decided the time was right to consider a strategic sale to another company, which could support Hohman’s growth for the next 100 years,” Kremer says. “During the due diligence process, we made Novaria aware of this expansion project, and they were very supportive of the growth plan and capital requirements necessary to achieve it.”

Getting the space to expand was an extremely lengthy project because Hohman is located near downtown Dayton and was landlocked by houses and other manufacturing operations on almost every side. With the support of Dayton City officials, who wanted to see Hohman grow and stay in the city, they spent the better part of the past decade buying homes and property when they came available until they had all the pieces they needed to put formal plans together for the expansion.

Working to Double Sales Again

This expansion project was one of the first things Kremer tackled when he arrived at Hohman Plating in 2015. He focused on increasing sales—which he did, doubling them from $ 18 million in the first eight years—while keeping an eye on how they could provide more throughout.

“As our sales and ambitions grew, the need for expansion became much more evident,” Kremer says. “We knew in 2015 that we were going to expand, and that's when we started acquiring properties on the next city block.”

“We believe our existing process will be more efficient and effective with the additional space. Small changes and additions to the process and additional space will allow us to tailor our work and abilities more closely to meet our customers’ needs.”

The acquisition process was slow. In the first four years through 2019, the company purchased nine parcels of property surrounding its location. It turned much of it into surface parking for its growing employee base until it could get enough land to start the construction.

New Modern Wastewater Treatment Facility to Handle Load

Building a modern wastewater treatment plant — with 12-foot wide tanks — that can handle all current and future operations is one of the most significant portions of the new construction.Building a modern wastewater treatment facility that can handle all current and future operations is one of the most significant portions of the new construction.

Building a modern wastewater treatment plant — with 12-foot wide tanks — that can handle all current and future operations is one of the most significant portions of the new construction.Building a modern wastewater treatment facility that can handle all current and future operations is one of the most significant portions of the new construction.

“We are utilizing 12-foot-wide tanks that almost didn’t fit through the doors,” says Jim Adolf, Technical Manager at Hohman Plating. “It is the centerpiece of the expansion.”

He says they will initially move four process lines to the new facility, which will almost immediately improve the quality of their operation.

“While it is a little cramped there today, there's certainly room for expansion,” Adolf says. “We believe our existing process will be more efficient and effective with the additional space. Small changes and additions to the process and additional space will allow us to tailor our work and abilities more closely to meet our customers’ needs.”

Adolf says Hohman will be more capable with the additional space for “add-ons” that some customers might request, a flexibility they may not have had in a more confined space.

“We need to be positioned to take all the growth we're looking at. I think having a new modern waste treatment system is an important part of what we're doing to ensure we're ready for whatever else we want to do,” Adolf says. .”

Designing New Process Systems

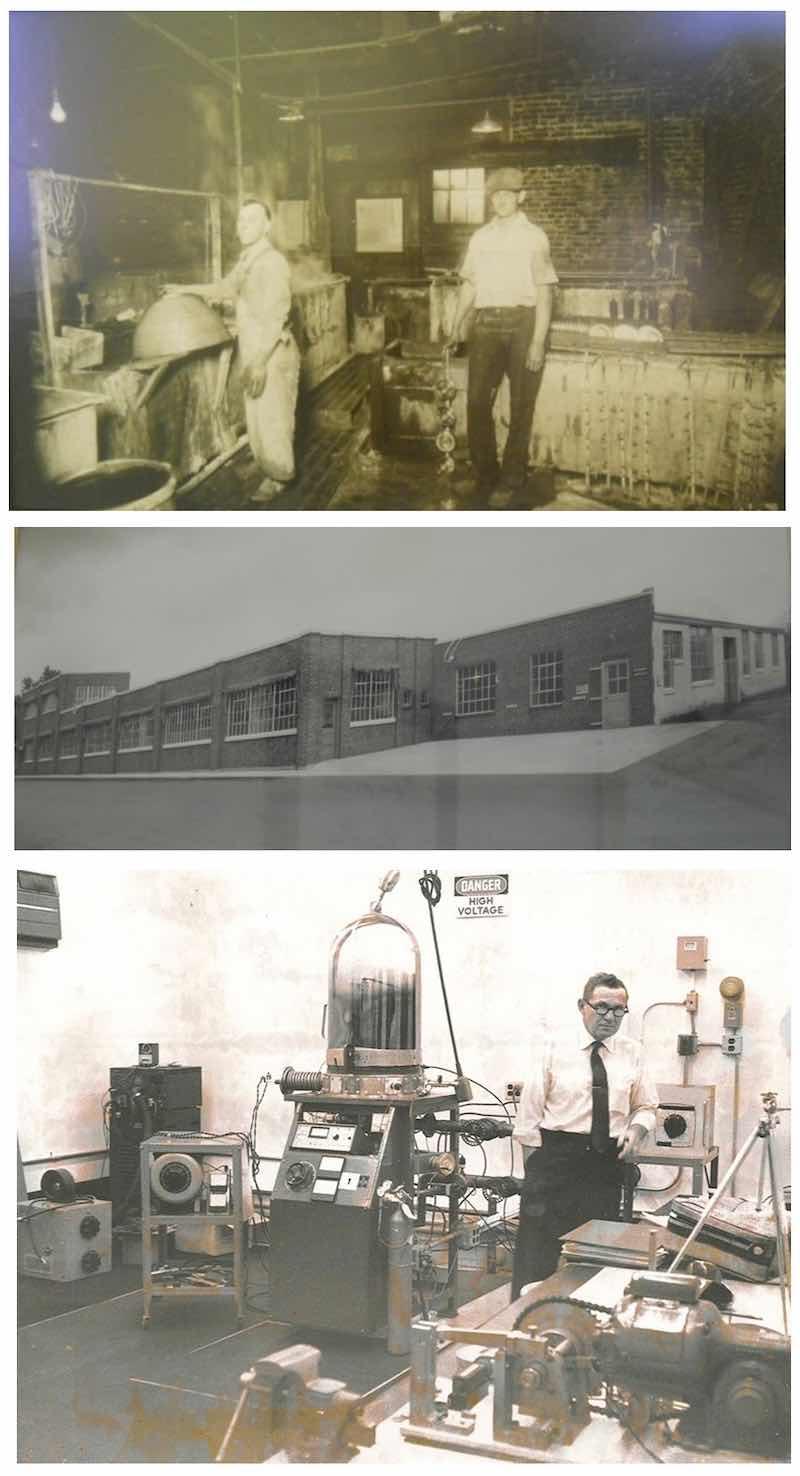

Hohman Plating’s history goes back to 2018 when William Hohman launched the company in Springfield, Ohio and moved it to Dayton in 1930 (top photo). Hohman moved into the old Kohler Aircraft Building in 1955 (middle photo) where it resides today. Former owner Bernard Stupp started one of the first vacuum coating departments in the U.S. in 1975 (bottom photo).Since Hohman has a team of on-staff engineers, Adolf says, “it was fun” designing the new process and wastewater treatment systems. Still, they relied on outside experts to confirm their plans met expectations.

Hohman Plating’s history goes back to 2018 when William Hohman launched the company in Springfield, Ohio and moved it to Dayton in 1930 (top photo). Hohman moved into the old Kohler Aircraft Building in 1955 (middle photo) where it resides today. Former owner Bernard Stupp started one of the first vacuum coating departments in the U.S. in 1975 (bottom photo).Since Hohman has a team of on-staff engineers, Adolf says, “it was fun” designing the new process and wastewater treatment systems. Still, they relied on outside experts to confirm their plans met expectations.

“It’s great that we can use our engineering knowledge, but we're working with some excellent partners to make sure that we get the best industry knowledge here and that we're not alone on the island,” Adolf says. “It's been a collaborative process with us here at Hohman and our partners, and of course, Bill and Todd have provided their input, which has been very helpful in ensuring that we’re benefitting from their experience.”

The new systems will also have additional automation and controls, including their barrel copper line and a workhorse for Hohman and its customers. Adolf says the key was to put the right technology in place to make the lines more efficient without buying too many expensive controls that don’t add to the production value.

“Certainly, the technology has advanced since the last time we built lines such as barrel copper,” he says. “The other lines won’t have a lot of automation except in the controls. We want to ensure that our operators have the right tools to do their jobs efficiently and effectively. It is difficult enough to do all our complicated plating, and to take the control operations off their plate is great. It just works better for them - we can't overstate how important it is for them to just be able to concentrate on doing a good job.”

When designing the new lines, Kremer says Hohman brought together nearly every department to give input and develop the plans, including the controls engineer, maintenance engineers, facility team, line operators, process engineers, and quality team.

“They were all involved in making the decisions about how to set up our new addition so that it met our customers’ needs first and foremost,” he says. “These people know our processes best, so it was important to have the entire team weigh in on improving the plans.”

Serving Existing Customers and Bringing in New Partners

General Manager Brad Kremer's goal is to double Hohman Plating's sales to over $70 million in several years with the addition of the new space.Kremer has been working closely with Kevin Harnish, Hohman’s Sales Manager, to book more work from existing and new customers across North America. They want to expand their zinc-nickel processes, aerospace primer applications, and physical vapor deposition work.

General Manager Brad Kremer's goal is to double Hohman Plating's sales to over $70 million in several years with the addition of the new space.Kremer has been working closely with Kevin Harnish, Hohman’s Sales Manager, to book more work from existing and new customers across North America. They want to expand their zinc-nickel processes, aerospace primer applications, and physical vapor deposition work.

“Our vacuum department has been very busy, and we may need additional space there,” Kremer says. “We've been asked to look at different cleaning processes, so we may need to add additional capacity for cleaning and preparing products for our customers. We were also recently approached about doing some electropolish work, which we are looking at, too.”

Growing the business and adding more space will require more employees in certain areas.

Hohman expects to add about 25% to 30% more employees, or roughly 50 more employees, to handle the growth in the coming years. The company has a strong four-person team in its Human Resources department that constantly recruits new team members, attends job fairs, and attracts a workforce to help it grow.

“Once you have that talented group of managers, you ensure you continue to bring on qualified and capable people at all levels inside the company. We are very fortunate to have a great workforce here at Hohman.”

“We don't use outside agencies to find staff; we use our internal team,” Kremer says. “And because we have been growing, adding resources to the HR team will ensure we can recruit ourselves.”

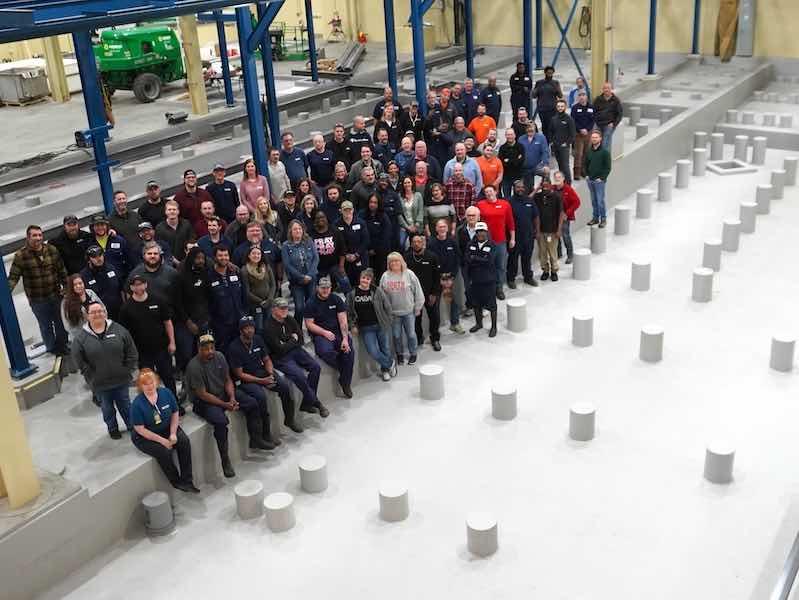

Hohman workers got to tour their new addition in March.Like most manufacturers, Hohman has often struggled to hire new employees in today’s economy and to find the right talent for its often sophisticated processes.

Hohman workers got to tour their new addition in March.Like most manufacturers, Hohman has often struggled to hire new employees in today’s economy and to find the right talent for its often sophisticated processes.

“I think the most important thing — once you get new team members here — is to make them feel welcome and ensure they have a career path and a training program,” Kremer says. “Most importantly, you remember that we are here to serve. Therefore, you hire talented people, give them authority and the resources to do their job, and continue to hire talented people. Once you have that talented group of managers, you ensure you continue to bring on qualified and capable people at all levels inside the company. We are very fortunate to have a great workforce here at Hohman.”

Visit www.HohmanPlating.com