Justin Guzman knows that traceability is the key to success — and sometimes even survival — in the aerospace industry regarding finishing parts.

Justin GuzmanHowever, the President of Aircraft X-Ray Laboratories (AXL) in Huntington Park, California, also knows many shops need help with the mountain of paperwork and the daily demand for documentation, especially receiving incoming shipments,

Justin GuzmanHowever, the President of Aircraft X-Ray Laboratories (AXL) in Huntington Park, California, also knows many shops need help with the mountain of paperwork and the daily demand for documentation, especially receiving incoming shipments,

“It’s not important until it becomes super important,” Guzman says. “From a chemical standpoint, when it comes to product lot numbers, expiration dates, Certificate Of Analysis, Technical Data Sheets, Safety Data Sheets, and other critical documentation when a shipment arrives, it can become extremely overwhelming.”

Guzman witnessed his shipping/receiving department making copies of all documentation that required sign-off to acknowledge receiving new supplies such as chemicals. Those papers would go to personnel at AXL, which handles chemicals and maintenance for Aircraft X-Ray, and the AXL reps would sign off that they had received the shipment and inspected it before storing it.

“I know that TrueLogic and Miles had to divorce themselves from some of their day-to-day operations to create this module,” Guzman says. “But it is crazy phenomenal how well it works.”

He also saw his people in the purchasing department get a copy of all the documents, as would the accounting staff and the laboratory team.

Digging Through Papers to Find Information

The TrueKeep module connects Miles’s QR coding network and the finishing shop’s network to better manage when chemistry gets to a shop by helping the shop manage its way through the intake and usage process.“We had files in files and files of documentation,” Guzman says. “But you would ask for one specific product that arrived on a certain date, and it could be a challenge to find the information easily. And, of course, in many instances, the one document you need, with an inspector looking over your shoulder, can’t be found.”

The TrueKeep module connects Miles’s QR coding network and the finishing shop’s network to better manage when chemistry gets to a shop by helping the shop manage its way through the intake and usage process.“We had files in files and files of documentation,” Guzman says. “But you would ask for one specific product that arrived on a certain date, and it could be a challenge to find the information easily. And, of course, in many instances, the one document you need, with an inspector looking over your shoulder, can’t be found.”

It was enough of a headache for AXL that Guzman discussed the issue with TrueLogic Company, a Texas-based software company known for its industry-leading TrueChem software suite and a long-time supplier to Aircraft X-Ray. Key to the discussion was California-based Miles Chemical, a long-time supplier to AXL, which has become a market-leading chemical services company for many industries, including the surface finishing sector, for almost 30 years.

The project's goal was to devise a way for customers to utilize technology to simplify and improve the way the shop received and managed its supply data.

Guzman says the discussion with TrueLogic and Miles began some time ago. He realized it was a large task to bring them together for just a single shop that needed to fix the issue of drowning in paperwork, but they enthusiastically agreed to proceed with the project.

Module Connects Suppliers’ and Finishing Shops’ Networks

Dan ZinmanThe result is a bolt-on software addition to TrueChem called TrueKeep. This module connects Miles’s QR coding network and the finishing shop’s network to better manage when chemistry gets to a shop and helps the shop manage its way through the intake and usage process.

Dan ZinmanThe result is a bolt-on software addition to TrueChem called TrueKeep. This module connects Miles’s QR coding network and the finishing shop’s network to better manage when chemistry gets to a shop and helps the shop manage its way through the intake and usage process.

“I know that TrueLogic and Miles had to divorce themselves from some of their day-to-day operations to create this module,” Guzman says. “But it is crazy phenomenal how well it works. We've integrated it into our inventory system, which adjusts when we add and subtract inventory and tells us when stock is low. We absolutely love what TrueKeep does for us.”

Dan Zinman, Vice President of Sales and Marketing at Miles Chemical, says Aircraft X-Ray Laboratories and Moog Aircraft Group in Torrance, CA, were the first shops to install the TrueKeep system, and it is working well to sync the info from Miles when deliveries are made.

“All that information is crucial and cannot be incorrect,” Zinman says.

“Before, transferring data was time-consuming, involved a lot of paperwork, and left a lot of room for human error, considering there's a constant shuffling of paperwork,” Zinman says. “Anytime we can make our customers more efficient and reduce possible errors, we are all for that.”

Recording Lot Numbers, Expiration Dates, and Chemical Type

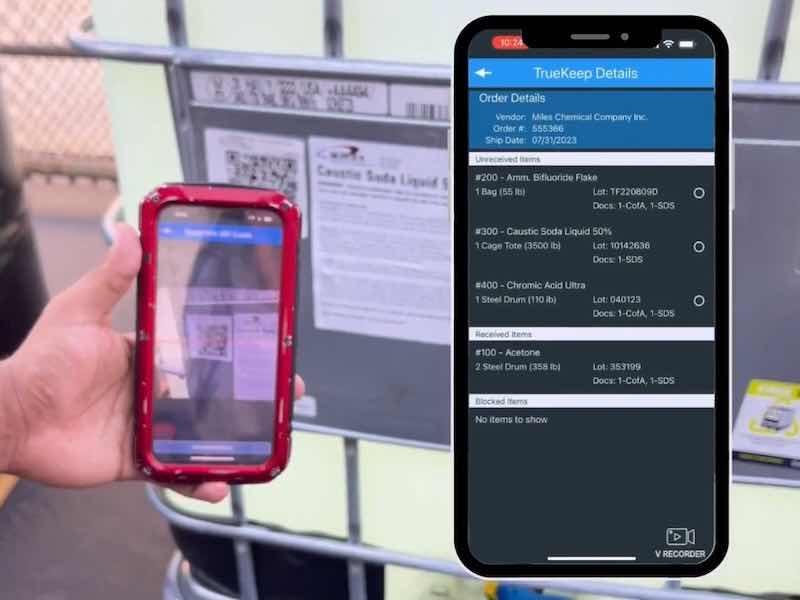

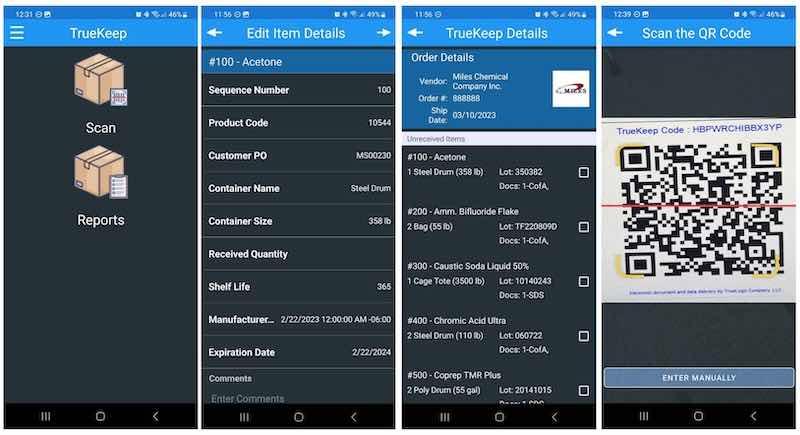

With TrueLogic’s new TrueKeep module, deliveries are simplified by allowing a shop employee to simply scan a QR code on the TrueKeep app, which pulls all the necessary information from the cloud onto their phone.Previously, shop employees would have to manually look for lot numbers, expiration dates, chemical type, and quantity when shipments arrived. They also had to ensure they had the latest data sheets and certifications for each chemical in the shipment.

With TrueLogic’s new TrueKeep module, deliveries are simplified by allowing a shop employee to simply scan a QR code on the TrueKeep app, which pulls all the necessary information from the cloud onto their phone.Previously, shop employees would have to manually look for lot numbers, expiration dates, chemical type, and quantity when shipments arrived. They also had to ensure they had the latest data sheets and certifications for each chemical in the shipment.

“All that information is crucial and cannot be incorrect,” Zinman says.

With TrueLogic’s new TrueKeep module, deliveries are simplified by allowing a shop employee to simply scan a quick-response (QR) code on the TrueKeep app, which pulls all the necessary information from the cloud onto their phone. The user then verifies the accuracy of the shipment by checking off all the received products and accompanying documentation.

The shipping information is downloaded on the spot and sent straight to the shop’s TrueChem database, which eliminates piles of paperwork. Matt Akin, CEO of TrueLogic, says this procedure centralizes all the important information from the delivery, thus ensuring the shipping information is accurate and easily accessible to anyone looking for it.

“We hear it every day that companies are trying to minimize human-machine interfaces because it's humans that get them in trouble,” Akin says.

“We’ve heard numerous stories where suppliers claim to have provided all the required paperwork for a shipment, but, for some reason, the customer can’t find the document(s) it needs,” Akin says. “Hours spent searching for paperwork are lost time, and often, they just don't have it on the receiving end.”

Eliminate Possible Human Error

Matt AkinThe TrueKeep system was designed to eliminate human error while putting all the records in one place. Akin says the new software model is a major step toward that goal.

Matt AkinThe TrueKeep system was designed to eliminate human error while putting all the records in one place. Akin says the new software model is a major step toward that goal.

“We hear it every day that companies are trying to minimize human-machine interfaces because it's humans that get them in trouble,” he says. "Now, shipments of any size can be received and inventoried with a click of a button. This is a very exciting advancement.”

As simple as the software module is to operate, it wasn’t exactly easy to design and make function. TrueLogic began rolling out the first edition of the software in late 2022 and tested it until the end of 2023, when they felt they had passed the beta stage.

“During the testing period, approximately 81 deliveries were tracked from Miles to AXL, or roughly 1.5 deliveries each week,” Akin says. That provided enough data for TrueLogic and Miles to feel confident the system was operating well enough to go live.

Roger Smith, TrueLogic’s Chief Technology Officer, says one of its customers had been asking for a feature like TrueKeep to be included in the TrueChem platform. The customer stated the need was due to mistakes caused by human error.

Adverse Finding Could Affect Quality Audits

“They were quite upset about data accuracy because they found some employees weren't entering lot numbers correctly into their system,” says Smith. He added the manufacturer had a major finding during a quality audit because of the errors.

“In addition to lot numbers being mistyped by the person receiving the deliveries, problems with incorrect expiration dates were also a big issue,” Smith says. “They were very concerned about getting accurate expiration dates transferred to the paperwork from the supplier. I think that is when they complained, ‘Hey, there’s got to be a better way to do this.’”

Originally, TrueLogic proposed putting QR codes on individual items that included the lot number, the manufacturer, the expiration date, and anything else that needed to be captured. But, Smith says, “It turned out to be a voluminous task for the supplier to generate a specialized barcode for every individual package on every pallet that goes out to the customer.

They also realized they couldn’t get all the data onto one specific QR code since some deliveries had as many as 200 different products on a truck for one shop. Smith said they found a solution by generating a QR code that was essentially a data table generated by the supplier at the time of the shipment, which mirrors the manifest shipping information.

Storage in the Cloud at TrueKeep

The Aircraft X-Ray Laboratories team in Huntington Park, California, loves the new TrueKeep module. "It is crazy phenomenal how well it works," says Guzman.“All of the shipping information gets rolled up and sent into the cloud; then a unique code is used to retrieve the info at the receiving end,” Smith says. “We wrap up any information the supplier has in their database about the products being delivered — including TDSs or SDSs— and we roll it up and put it into a storage place in the cloud called TrueKeep.”

The Aircraft X-Ray Laboratories team in Huntington Park, California, loves the new TrueKeep module. "It is crazy phenomenal how well it works," says Guzman.“All of the shipping information gets rolled up and sent into the cloud; then a unique code is used to retrieve the info at the receiving end,” Smith says. “We wrap up any information the supplier has in their database about the products being delivered — including TDSs or SDSs— and we roll it up and put it into a storage place in the cloud called TrueKeep.”

The person at the shop receiving the shipment scans the QR code with a TrueKeep phone app to retrieve all the information and tells the software where to save it.

“Ultimately, the customer can unwrap that info and put it anywhere they want,” Smith says.

Guzman says the software seamlessly and quickly performs tasks that had previously required significant time for his AXL team. All too often, these tasks were redundant because other employee(s) were performing the same activities in their department with duplicate copies of the paperwork.

“Ease of use is always at the forefront,” Akin says. “We constantly remind ourselves that if it isn't easy to use, they won't use it.”

For example, Guzman says that with every chemical bag delivered to his facility, they must acknowledge the product's expiration date, access the proper documentation, and enter the information on lots for traceability purposes. That is where things can go wrong if workers do the work by hand.

“Was it an eight or a five that they wrote down?” Guzman asks. “Before TrueKeep, we wouldn't know there was an issue until two or three months later when we went looking for something for a customer and heard, ‘Hey, this lot number doesn't exist for the paint.’ But electronically, you know it's 100% correct. The traceability, the reduction in human error, and the efficiency—it's just tremendous for us.”

Suppliers Like Complete Automation, Too

Zinman says his team at Miles Chemical also loves TrueKeep.

“You don't have the emails that say, ‘Can you resend my Cert? We had it, but one of my guys lost it,’” he says. Or we would get a call about some expired product, only to find they entered the wrong number in their system. TrueKeep completely automates it, and it is very user-friendly. The fact that you can use your smartphone, so it doesn’t require sophisticated equipment or scanner, makes it even better.”

Akin says TrueLogic is about to surpass 500 TrueChem installations worldwide, and they are working on getting those shops and their suppliers to add TrueKeep to reduce the errors and improve traceability required in so many accreditation programs.

“One of the keys to building this module was to ensure ease of operation, making sure it wouldn’t be a burden to use,” Akin says. “As Roger and the team are adding features/modules to the software, ease of use is always at the forefront. We constantly remind ourselves that if it isn't easy to use, they won't use it.”

Visit https://aircraftxray.com, https://moog.com, https://truelogiccompany.com, https://www.truekeep.com, andhttps://www.mileschemical.com.