Most 50th-anniversary gifts involve something made of gold, be it a watch, jewelry, or some gilded object to celebrate a half-century of effort.

Bales Metal Surface Solutions’ owners, Stacey Bales and Sara Mortensen, chose a practical gift for themselves as they prepare for their anniversary in a few years.

In March, the Downers Grove, Illinois, company christened a pair of new nickel lines at its 29,000-square-foot facility, doubling its capacity to reduce customer lead time by half and grow the business even more.

“We’re hoping our 50th year in business is going to be a bang-out one,” says Bales, whose late father started the company with his brother in 1978, giving them four years to meet some pretty big sales goals they have set for the shop.

Expanded Plating Capacity from 5 to 10 Tanks

Owners Sara Mortensen and Stacey Bales, and Mike Hill, operations manager at Bales Metal Surface Solutions, celebrate the opening of their new lines.Installing the new nickel lines expanded Bales’ plating capacity from five to 10 tanks and introduced a counterflow rinse and hoist system to accommodate heavier parts.

Owners Sara Mortensen and Stacey Bales, and Mike Hill, operations manager at Bales Metal Surface Solutions, celebrate the opening of their new lines.Installing the new nickel lines expanded Bales’ plating capacity from five to 10 tanks and introduced a counterflow rinse and hoist system to accommodate heavier parts.

The new lines replaced aging ones that were put in by founders Steve and Mike Bales almost two decades ago.

The new lines come with some hefty expectations from the company's leaders, who also provide hard chrome and diamond chrome plating, finishes, and other services for preparing and processing metal components for surface finishing.

“We are working to build the company up, and we have some big revenue and employee headcount growth goals over the next five years,” Bales says, adding that they plan to increase their current 28 employees to almost 50.

“We are hoping to double almost the headcount in the next five years,” she says. “We have some pretty grand expectations.”

Bales Metal Surface Solutions has begun an apprenticeship program at the company. One aspect of hiring more people is to show them that working there can be a career. Both Bales and Mortensen have seen firsthand how many younger workers start their careers at the company and might eventually head off to another job where they hope to seek larger roles.

Developing Talent and Convincing Them to Stay

A before and after of the reutilized space where the new lines were installed.They hope to change that by developing talent that comes through the door and, more importantly, convince them to stay and build a career at Bales.

A before and after of the reutilized space where the new lines were installed.They hope to change that by developing talent that comes through the door and, more importantly, convince them to stay and build a career at Bales.

“The first step right is, once you get them in the door, you have to show them how they can grow here and why it's worthwhile for them to build a career,” Bales says. “Step two shows them that even though we don't have 17 supervisor positions opened up, there is still a way for you to grow within your position here and how you can elevate on your own.”

Employee referrals are the biggest way that Bales and Mortensen have seen their workforce grow, and they have worked hard to develop a culture where employees will recommend to family and friends when a position opens.

“Our team members deserve the resources to excel at Bales and beyond, which is why we prioritize ongoing education,” Mortensen says. “They can participate in formal and on-the-job training, mentoring and coaching, job rotations, and industry conferences at no cost. We empower employees with the knowledge and skills to work autonomously and encourage their input.”

Because Bales Metal Surface Solutions is a family-owned business, both owners have diligently treated employees right, respected their work-life balance, and recognized team members for their hard work.

“Bales has set the standard for culture among Chicago area manufacturers,” said Kathy Gilmore, president of the VIA.

As proof, the company won a 2024 award for excellence in manufacturing in the “Culture, Small Division” category at the annual Spark Awards presented by the Valley Industrial Association, which honors the best Chicago-area manufacturers. It was a competitive category, as companies completed a detailed benchmarking self-assessment that measured their aptitude in six categories. Those with the highest benchmarking results become finalists, and a panel of industry experts interviews the finalists to determine winners in each category.

Setting the Standard for Culture Among Chicago Manufacturers

Bales Metal Surface Solutions has become well-known for partnering with mold makers in the industrial tooling industry.It was the second consecutive year that the VIA recognized Bales as a finalist in the Culture category, and Spark also recognized Bales as a finalist in the Workforce Development category.

Bales Metal Surface Solutions has become well-known for partnering with mold makers in the industrial tooling industry.It was the second consecutive year that the VIA recognized Bales as a finalist in the Culture category, and Spark also recognized Bales as a finalist in the Workforce Development category.

“Bales has set the standard for culture among Chicago area manufacturers,” said Kathy Gilmore, president of the VIA. “This award is a testament to their commitment to best practices and continuous improvement.”

The judges say Bales Metal Surface Solutions fosters an “employee-centric environment” and cited the seamless transition of a chrome plating technician into an accounts payable role following further education.

“Their commitment to employee well-being is evident through a comprehensive health program, including biometric screenings and wellness fairs,” the VIA judges wrote when making Bales the winner. “Additionally, initiatives like the Bales’ farmers market address food insecurity, while inclusive events like open houses with family participation foster a strong sense of community.”

Bales and Mortensen say the award confirmed their goal of attracting and keeping the right workers at the company.

“We've focused a lot on employee culture and treating them like family,” Bales says. “I know what I expect and what I enjoy as far as benefits and perks. “We want to be humanistic, so we pass along much of that and try to build it into our policies and benefits package. We're grateful that our employees see that, and we've built a great culture. As a result of that, they're helping us recruit the best of the best.”

The Bales team celebrated the new lines with a ribbon cutting ceremony for its staff.

The Bales team celebrated the new lines with a ribbon cutting ceremony for its staff.

Growing Sales with New and Existing Lines

A fully developed workforce will be critical for Bales Metal Surface Solutions as it tries to grow sales with its new and existing lines. The company has become well-known for partnering with mold makers in the industrial tooling industry. This history goes back to when Steve and Mike Bales started Bales Mold Service in a 1,000-square-foot space in Brookfield, IL, where they initially offered diamond polishing services.

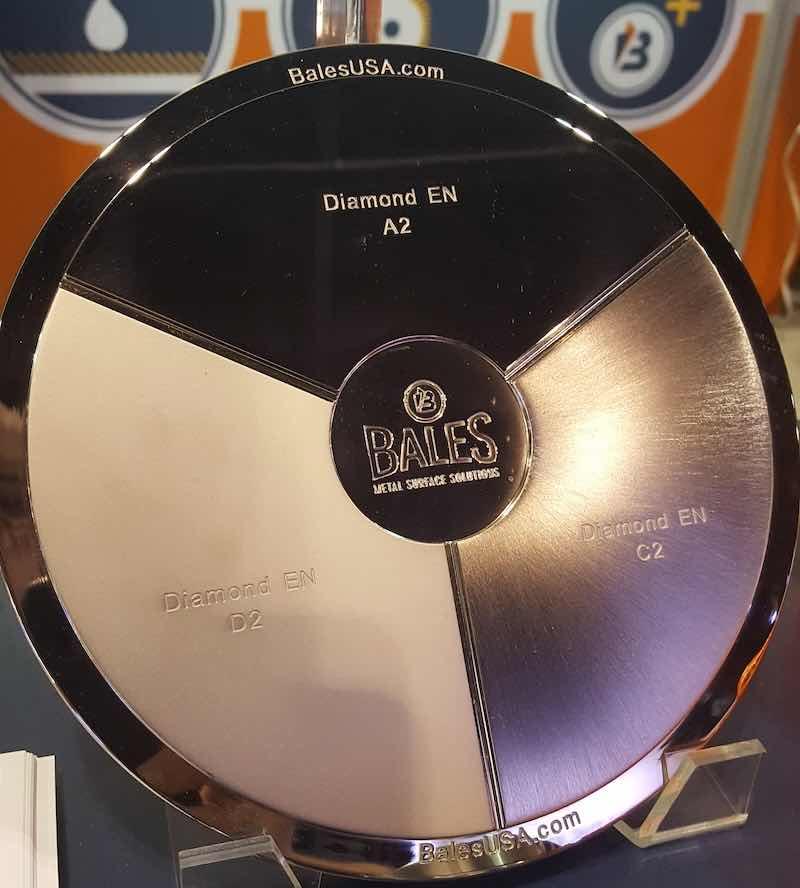

The company has developed several proprietary coatings that are specifically designed for mold makers.In 1985, Bales built and moved to a 15,000-square-foot facility in Downers Grove, where the relocation allowed them to add electroless nickel and chrome plating services. A few years later, the company saw the need for new coatings to improve mold release and lubricity and introduced a nickel Teflon coating called Nicklon, which it trademarked.

The company has developed several proprietary coatings that are specifically designed for mold makers.In 1985, Bales built and moved to a 15,000-square-foot facility in Downers Grove, where the relocation allowed them to add electroless nickel and chrome plating services. A few years later, the company saw the need for new coatings to improve mold release and lubricity and introduced a nickel Teflon coating called Nicklon, which it trademarked.

In 2001, they developed a new proprietary chemistry, Diamond Chrome, for coating applications requiring extreme hardness. They continued developing their own chemistry and 2003 began marketing NiBore, which combined electroless nickel and boron nitride particles for superior lubricity and hardness.

“Some of our customers mold glass-filled materials, so having super abrasive resistant things is their top priority,” Stacey Bales says. “Others operate in wet environments, so their corrosive properties are important. We try to listen to our customers and understand their challenges, and then we help guide them to a coating or a service that we think will best suit their needs.”

Bales Metal Surface Solutions developed an online Coating Comparison Tool built into their website to assist their customers in making those decisions. They turned what was once a large poster they would give mold makers to hang in their shops into an online tool to help customers decide what coating they need based on hardness, coefficient of friction, temperature, corrosion-resistance level, abrasion resistance, and release rating.

“We try to solve our customer’s pain points and help them prove out ROI on some of the different things they can do to protect the life of their molds,” Stacey says.

Mortensen created the system, wanting to keep it as up-to-date as possible as mold makers' needs changed.

“We wanted the coating information to be more interactive,” Mortensen says. “With the Coating Comparison Tool, users can evaluate the best finishing solution for their pain point by selecting up to three coatings and viewing their properties side-by-side.”

Cycle Savings Calculator Helps Moldmakers Pick the Right Coating

Owners Sara Mortensen and Stacey Bales, and Mike Hill, operations manager at Bales, dedicate their new lines.Mortensen also helped drive another Bales website feature, the Cycle Savings Calculator. Developed in partnership with Red Caffeine, a growth consultancy, it is a tool plastic injection firms and other manufacturers can use to determine how many more parts they can produce by improving their cycle time.

Owners Sara Mortensen and Stacey Bales, and Mike Hill, operations manager at Bales, dedicate their new lines.Mortensen also helped drive another Bales website feature, the Cycle Savings Calculator. Developed in partnership with Red Caffeine, a growth consultancy, it is a tool plastic injection firms and other manufacturers can use to determine how many more parts they can produce by improving their cycle time.

“Manufacturers know that the right metal surface treatment can boost productivity, but we want to help them put a number to it,” Mortensen says. “Understanding the impact of surface finishing on productivity allows manufacturers to make strategic finishing decisions that grow their efficiency, cost savings, and competitiveness.” Slower cycle time often signals poor part quality, and productivity rises when metal tooling has optimal protection against abrasion, wear, and corrosion. Bales’ Cycle Savings Calculator helps manufacturers obtain the ideal surface treatment, improving part functionality and cycle time.

“The more that their plastic is sticking to the mold, the fewer parts they're able to produce,” Bales says. “Adding different coatings and reducing friction can help them produce more parts. We've even seen case studies where we had a customer going in, and after so many shots, the plastic would start sticking to the mold. They had operators physically going into the mold to clean it, which resulted in many workers comp injuries because they were going in and trying to clean hot molds.”

Bales says their company can work with the customer to apply a more durable coating, which results in less cleaning.

“We try to solve our customer’s pain points and help them prove out ROI on some of the different things they can do to protect the life of their molds,” she says. “The advantage for us to trademark those coatings is that our customers eventually will start calling those out on specs and can only send those parts to us.”

“Our customers value quick turnaround, and so do we,” Mortensen says. “The new nickel lines have doubled our nickel plating capacity, which means lower lead times.”

Bales credits her shop’s full-time in-house chemist, Jamie Santiago, with developing proprietary chemistries that make a big difference with many of the mold makers they call customers.

“He's amazing, and we say he's our mad scientist,” Bales says. “When we present challenges to him, he's pretty creative at finding solutions. The Diamond E.N. , in particular, was developed because we started having customers who were starting to shy away from the chrome a little bit more. However, they still needed that hardness and the abrasion properties that the Diamond E.N.™ now has.”

Making Extra Space ‘Come to Life’ for Increased Production

“We are hoping to double almost the headcount in the next five years,” Stacey Bales says.Bales and Mortensen are counting on the new nickel lines—and the added capacity they bring—to help propel the company over the next several years and well into the future. That is why they painstakingly took their time—over three years, to be exact—to plan for the expansion and the addition of the new lines.

“We are hoping to double almost the headcount in the next five years,” Stacey Bales says.Bales and Mortensen are counting on the new nickel lines—and the added capacity they bring—to help propel the company over the next several years and well into the future. That is why they painstakingly took their time—over three years, to be exact—to plan for the expansion and the addition of the new lines.

“Our customers value quick turnaround, and so do we,” Mortensen says. “The new nickel lines have doubled our nickel plating capacity, which means lower lead times. Plus, now that we have more space, we can continue developing new coatings and services to address manufacturers’ finishing challenges.”

Before their father’s sudden passing in 2009, he expanded the business by adding to their building, but it has remained relatively unused as a production area since then. Bales and Mortensen then watched the economy and customer demands to find a good time to renovate and expand the capabilities.

“We've been trying to figure out exactly how we wanted to make that space come to life,” Bales says. “And this was always part of the plan, but between the recession, COVID, and other wonderful surprises, it just took us a little longer to get the new equipment we had expected.”

Of course, since no two shops are alike, the Bales Metal Surface Solutions site had to be custom-engineered to fit the space and meet the shop's specifications. In doing so, the Bales team worked with three respected suppliers in the finishing industry:

- Plating Specialists for help with the design and system installation

- John Schneider & Associates from Wisconsin also helped design the system.

- Corrotec, which manufactured and installed the Lines.

Better Rinsing and Automated Controls on Plating Baths

Bales says it was a deliberate process to work with the suppliers to design the system correctly and build it on budget. Their team spent a lot of time looking at many new advancements and technologies, including better rinsing, better controls on the plating baths, and automated controls on the plating baths.

Bales says it was a deliberate process to work with the suppliers to design the system correctly and build it on budget. Their team spent a lot of time looking at many new advancements and technologies, including better rinsing, better controls on the plating baths, and automated controls on the plating baths.

“We couldn't just go to a catalog and pick out something because we didn't need a one-size-fits-all system,” she says. “We needed a company that would listen to our challenges and discuss ways to make things more flexible. We needed the ability to run the lines how we need to run them today, depending on what work is in-house. It's great to see it all come to life.”

Mike Hill, operations manager at Bales Metal Surface Solutions, says the new lines will increase productivity and better serve the company’s customers.

“In addition to faster turnaround times on nickel plating, customers can expect even better plating quality and consistency, such as color and shininess,” Hill says. “The new equipment rinses parts more effectively and provides easier tank access for daily quality checks.”

One of the project's biggest challenges is that Bales Metal Surface Solutions is a zero-discharge facility, so it was crucial to pay close attention to any additional burdens placed on its waste treatment system.

“We were concerned about mitigating those counterflow rinses and the additional rinse water, especially how we were going to maintain our zero discharge status,” Bales says. “We could work all those out through the design, and everything came out exactly as we wanted.”

Working with Experienced Suppliers to Future-Proof Lines

Briane GreeneWorking with Plating Specialists, JSA, and Corrotec reassured the Bales team, as each company has extensive experience working with shops on these projects.

Briane GreeneWorking with Plating Specialists, JSA, and Corrotec reassured the Bales team, as each company has extensive experience working with shops on these projects.

Bales says Michael Lindemann, a business development manager at JSA, was especially helpful in the project. Lindemann has been working with the shop for many years. She also singled out PSI President Brian Greene as being there for them when important decisions had to be made.

“We had some great people to work with, like Mike Lindemann, who has been a long-time supplier for us,” Bales says. “No matter what the challenge, if you call him, he's going to help you, and he's going to reach out to his network and find solutions. When we started talking about these new plating lines, the first name that popped up for him was Brian Green at Plating Specialists, and we brought him out. It was a great conversation, good synergy, and those guys are patient beyond words.”

“It opens up more windows for us to get creative and add more services.”

Greene says that the project was the true definition of a partnership.

“The team took the time to clearly understand customer requirements today and the requirements of tomorrow,” he said. “Bales has made a significant investment into their future. We are proud to be a part of their journey.”

Ben StrattonBen Stratton, Corporate Affairs Manager at Corrotec, says their involvement with Bales began many years ago after the shop had installed large, overhead power-assisted hoists but no tanks. They had a vision of a large EN production area for aluminum and steel.

Ben StrattonBen Stratton, Corporate Affairs Manager at Corrotec, says their involvement with Bales began many years ago after the shop had installed large, overhead power-assisted hoists but no tanks. They had a vision of a large EN production area for aluminum and steel.

“When we met with them at their facility, it was easy to see they knew the end result they wanted,” Stratton says. “All they needed was someone to listen and connect their existing hoists and plant to that end result.”

In partnership with Plating Specialists, Corrotec developed two systems side-by-side in the space. Stratton says it was clear from the start that the Bales-Corrotec-PSI project team was going to be a good one.

“During the design phase, we modified our plans to fit their operational, safety, compliance, and space needs; it is truly a custom-fit system,” he says. “Due in large part to the strong cooperation among the project team, the installation went extremely well, even when confronted with a few challenges.”

He added that the team Bales team had a great vision of what they wanted, which made it enjoyable to work with the company.

“We enjoy working with customers who know what they want,” Stratton says. “It allows us to make a custom-solution that fits that vision perfectly.

Both Bales and Mortensen's biggest concerns were ensuring that the new lines and the improvements to the shop could meet today’s needs and the company's future growth.

“We wanted to make sure that this line was going to be able to sustain us into the future as well,” Bales says. “So we over-added plating tanks on this line, knowing that we're probably not going to use all of them straight out of the gate, but it'll give us a lot of flexibility to be able to. We added duplicate plating tanks for the work that's coming in today, and then, in the future, we will be able to add new nickel products and services at the end of the line. It opens up more windows for us to get creative and add more services.”

Visit https://www.balesusa.com.