Varland Plating has provided electroplating service for nearly 80 years but knew it needed to increase its efficiencies through digitalization.

Toby VarlandLocated in Cincinnati, the company specializes in bulk barrel electroplating, processing thousands of different parts for hundreds of different customers across a wide range of industries, including:

Toby VarlandLocated in Cincinnati, the company specializes in bulk barrel electroplating, processing thousands of different parts for hundreds of different customers across a wide range of industries, including:

- Automotive components range from internal engine parts to fasteners used on fuel covers.

- Military parts that are used in a wide range of applications, including next-generation military vehicles.

- Firearm components and ammunition.

- Fasteners and components for furniture and retail.

- Electrical components range from service delivery hardware to individual breaker components.

From Manual Methods to Automation

Varland performed plating operations manually for years, but electroplating is a complex process. For example, barrel plating requires:

- Controlling barrel rotation speed and direction with Variable Frequency Drives (VFDs).

- Tracking the movement of parts throughout the plating line, including tracking how long parts spend in each step of the process.

- Maintaining precise vat temperatures, fluid levels, and pH/conductivity readings.

- Managing automated chemical feeds.

- Applying and tracking precise electrical current using a rectifier to facilitate electrolysis results in metal ions deposition onto the components.

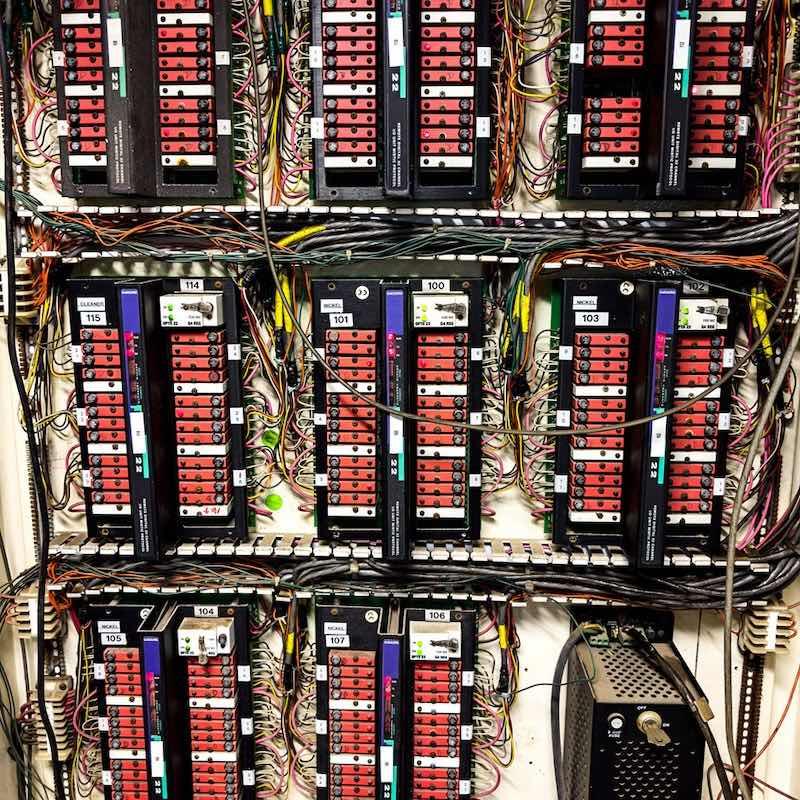

Varland has always strived to push the boundaries in terms of quality and efficiency. In the early 1990s, Varland engineers began automating plating processes where possible. Their decision to use Opto 22’s SNAP-LCM4 controllers, mistic racks with G4 single-point I/O, and FactoryFloor flowchart-based programming software helped Varland establish a reputation in the industry.

“Our early adoption of electroplating automation allowed us to excel in producing high-quality work for challenging jobs,” says Toby Varland, the shop’s Vice President of Technology. “This also enabled us to offer better-than-average turnaround times and consistent product quality.”

From Serial Systems to Ethernet

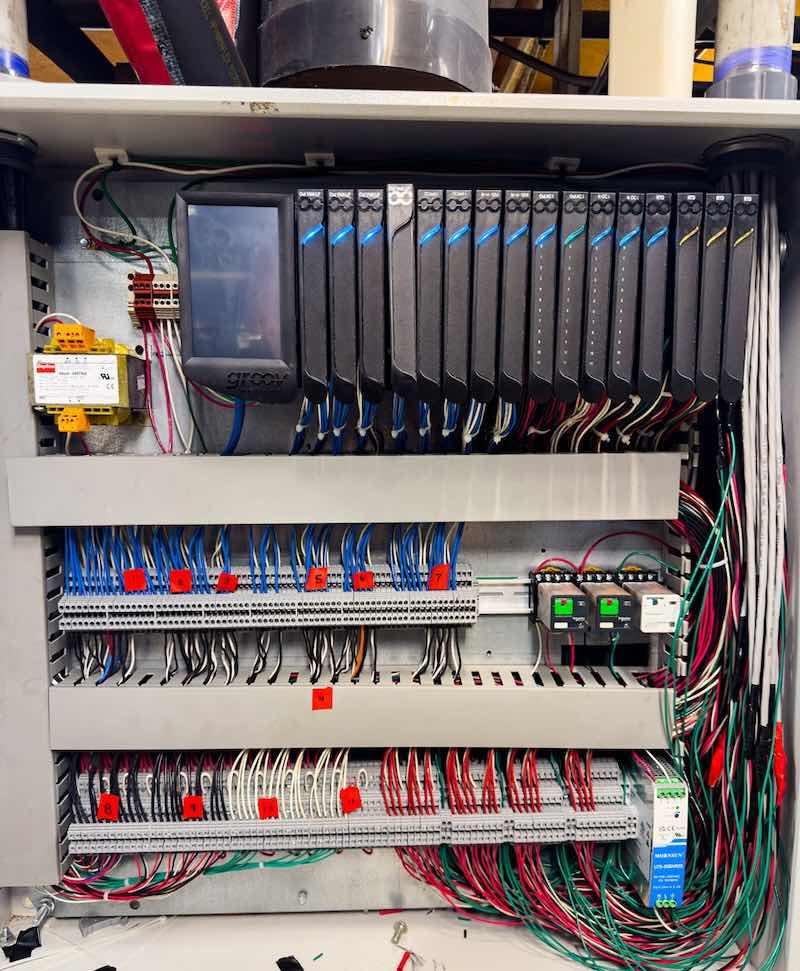

Opto 22’s latest Groov EPIC system supports four serial ports.Automation advanced Varland’s business objectives for decades, but as time passed, the limitations of legacy hardware became evident.

Opto 22’s latest Groov EPIC system supports four serial ports.Automation advanced Varland’s business objectives for decades, but as time passed, the limitations of legacy hardware became evident.

“Every barrel on our automatic plating lines has an RFID [radio frequency identification] tag, and our hoists use serial RFID readers to help us track jobs through production,” Varland says. “Each SNAP-LCM4 controller supports a maximum of four serial ports. At least one of those ports had to be reserved for I/O, so we were limited to a maximum of three RFID readers per controller.”

The limited number of serial ports necessitated daisy-chaining dozens of I/O racks on individual serial communication ports and, in some cases, expanding the architecture to add additional processors. This setup led to increased communication latency, potential data collisions, and complicated troubleshooting, ultimately hindering system performance and reliability.

In contrast, Varland says that a single GRV-CSERI-4 serial module on Opto 22’s latest Groov EPIC system supports four serial ports, and a single EPIC processor can support up to 4 of those modules, equating to 16 individual serial connections on one controller.

“Hooking up RFID readers to serial modules on EPIC allows us to condense to a single processor per plating line,” he says.

While serial communications still have their place in Varland’s process, Varland says he knows that Ethernet—not serial communication—is the future of industrial automation.

“We could theoretically keep running SNAP-LCM4 processors,” he says. “Most of our systems have been running reliably for many years. But these newer [groov] products just have so much more capability in every aspect, from installation to programming to operator experience, that they do a great job of getting out of the way and making it easier for our staff to do their jobs.”

I/O Upgrade: A Piecemeal Approach

Using Opto 22’s open-source friendly REST API, the shop deployed a suite of PHP command-line scripts that retrieve I/O and critical data values and log them into an InfluxDB time series database.A common pain point in upgrading control systems is replacing and rewiring I/O. With several thousand digital and analog I/O points running key systems at the shop, Varland says “rip and replace” is not a viable upgrade path. Shutting down the entire operation is not an option, so he explains that they have “put a lot of thought into the upgrade path.”

Using Opto 22’s open-source friendly REST API, the shop deployed a suite of PHP command-line scripts that retrieve I/O and critical data values and log them into an InfluxDB time series database.A common pain point in upgrading control systems is replacing and rewiring I/O. With several thousand digital and analog I/O points running key systems at the shop, Varland says “rip and replace” is not a viable upgrade path. Shutting down the entire operation is not an option, so he explains that they have “put a lot of thought into the upgrade path.”

Varland engineers decided to upgrade I/O systems one rack at a time.

“Of course, LCM4 processors running FactoryFloor software from the 1990s can’t directly address I/O registers on a brand new Groov EPIC I/O rack,” Varland says. But a clever workaround enabled Varland to avoid a costly downtime situation. Using Opto 22’s “scratch pad” — a temporary memory storage area for data exchange between controllers and I/O processors — Varland can map EPIC’s I/O channels to internal memory registers their legacy SNAP-LCM4 controllers can access.

Open communication between legacy and new equipment enables them to maintain the existing program on legacy hardware while developing a new one in parallel.

“The control logic on the LCM4 doesn’t change,” Varland says. “We can start developing a new solution on the Groov EPIC. For testing, I can flip a switch, do some testing, and then flip back to the old program.”

Identifying Insights

With critical process variables now available in a modern Ethernet communication interface, Varland faced their next challenge: limited visibility and no long-term trend analysis.

A savvy use of free resources helped Varland advance his company’s understanding of its processes with some software development, specifically a homegrown data historian. Using Opto 22’s open-source friendly REST API, the shop deployed a suite of PHP command-line scripts that retrieve I/O and critical data values and log them into an InfluxDB time series database. The data is then visualized and contextualized using Grafana, an open-source monitoring platform.

Digital Transformation is Never Done

Varland decided to use Opto 22’s SNAP-LCM4 controllers, mistic racks with G4 single-point I/O, and FactoryFloor flowchart-based programming software.Varland’s homegrown data historian was a step forward, but scaling homemade data collection scripts is challenging. Maintaining continuity poses a risk as the system grows, especially if the original developer becomes unavailable. They needed a scalable platform with professional support and documentation to ensure long-term reliability in SCADA.

Varland decided to use Opto 22’s SNAP-LCM4 controllers, mistic racks with G4 single-point I/O, and FactoryFloor flowchart-based programming software.Varland’s homegrown data historian was a step forward, but scaling homemade data collection scripts is challenging. Maintaining continuity poses a risk as the system grows, especially if the original developer becomes unavailable. They needed a scalable platform with professional support and documentation to ensure long-term reliability in SCADA.

It’s a good thing Varland understands that digital transformation is an ongoing process because, in 2023, it took another turn.

“Through Groov EPIC, we learned about [Inductive Automation’s] Ignition, and we feel we can leverage the software to accomplish a lot of SCADA goals that we haven’t yet hit,” Varland says. “We started with an Ignition Edge license on one of our Groov EPICs, and I liked it enough that we bought a full Ignition license that we now run on an Apple Mac Studio server.”

He says InfluxDB and Grafana worked well for long-term storage and trend analysis.

“Ignition allows us to remove the pain point of custom data collection and allows us to use Ignition Historian as a passthrough to get data into InfluxDB more reliably and with significantly less work,” Varland says.

Showing Impactful Results

Varland says there have been significant impacts on their Groov EPIC and Ignition upgrades.

“Getting data into a historian platform where we can be flexible about how we access and study that data has given us new insights into our processes,” he says. “We’ve reduced downtime, improved our operator experience, and freed our operators to focus on parts and quality. No one doubts the impact, although it’s hard to measure.”

When customers tour their facility, Varland says they are impressed by the shop’s tight control over their processes.

“When customers see those screens, they realize we aren’t dependent on vendors to update our systems,” he says. “We do it all ourselves and have full control over our automated systems. Other automation companies tell you it’s time for an upgrade, while Opto 22 helps us troubleshoot 30-year-old control systems.”

Next Steps in the Transformation

Varland’s plans include Groov EPIC upgrades for several more automated lines, full migration to Ignition for HMI and SCADA, and exploration of CODESYS for IEC 61131-3 compliant PLC programming languages. Varland’s digital transformation journey has been just that— a journey — and the shop knows that is how it’s supposed to be: digital transformation is never complete. To use a car analogy, it’s not just about driving from point A to point B but about continuously enhancing the vehicle itself.

Varland’s plans include Groov EPIC upgrades for several more automated lines, full migration to Ignition for HMI and SCADA, and exploration of CODESYS for IEC 61131-3 compliant PLC programming languages. Varland’s digital transformation journey has been just that— a journey — and the shop knows that is how it’s supposed to be: digital transformation is never complete. To use a car analogy, it’s not just about driving from point A to point B but about continuously enhancing the vehicle itself.

Varland’s plans include Groov EPIC upgrades for several more automated lines, full migration to Ignition for HMI and SCADA, and exploration of CODESYS for IEC 61131-3 compliant PLC programming languages. However, they know there is still a long way to go.

All these upgrades require much effort from the shop’s engineers and technicians, but Varland says the value of working with a trusted partner in automation.

“It’s hard to quantify the value of the relationship you can have with Opto 22,” he says. “Whether that’s a simple thing like the factory-manned OptoForums or calling on the phone and speaking with a tech support person who is a knowledgeable, high-level employee.”

Opto 22 was started in 1974 by a co-inventor of the solid-state relay (SSR), who discovered a way to make SSRs more reliable.

Opto 22 has consistently built products on open standards rather than proprietary technologies. The company developed the red-white-yellow-black color-coding system for input/output (I/O) modules and the open Optomux protocol and pioneered Ethernet-based I/O.

Famous worldwide for its reliable industrial I/O, the company introduced Groov EPIC (edge programmable industrial controller) in 2018. EPIC has an open-source Linux OS and provides connectivity to PLCs, software, online services, data handling and visualization, and real-time control.

Groov RIO Ethernet-based edge I/O modules — introduced in 2020 — include I/O and IIoT software in a compact industrial package that goes anywhere. All Opto 22 products are manufactured and supported in the U.S.A. Most solid-state SSRs and I/O modules are guaranteed for life.

Visit https://varland.com and www.opto22.com.