Foresight Finishing has been granted Nadcap heat treating accreditation following the successful conclusion of audit 204272. The Tempe, Arizona-based shop specializes in plating connector contacts, RF components and loose piece contacts.

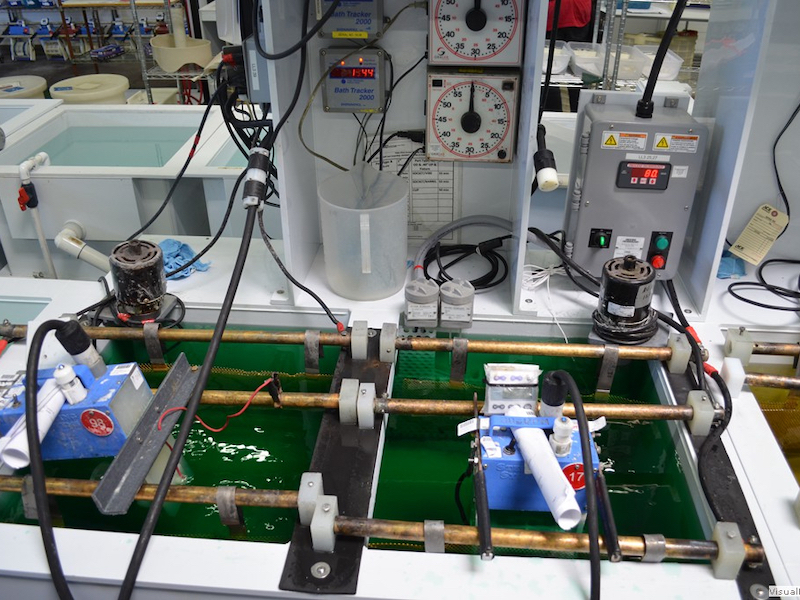

Typical parts have tolerances as tight as +/- .0002. The finished parts pictured in the blue container to the right measure .1481” in length and .012” in diameter, and there are approximately 10,000 of these parts. Parts on the left are a result of Foresights pristine pre-clean and heat treat process.

“Our customers all across the United States have been utilizing our Nadcap accredited plating processes, but major OEMs are now starting to flow down Nadcap heat treat in the electronics industry,” says Casey Weizel, co-founder of the company along with his brother, Joe.

“For the past few years, we’ve had a number of customers request that we add heat-treating to our list of competencies,” he says. “Two years ago, we brought heat treat in-house, and we perfected the process for the ultra-small precision parts that are the cornerstone of our business.”

The contacts and connectors Foresight plates are typically used in the aerospace and defense industries. As such, just like plating for these industries requires Nadcap accreditation, they would also require Nadcap for heat-treating.

Heat Treating Ultra-Precision Small Parts

“We’ve been heat treating for the past couple of years, but only for customers who didn’t require Nadcap accreditation,” Casey says. “That being said, it has always been part of our business plan to achieve Nadcap accreditation for heat treating. Our customers regularly tell us that standard heat treat companies who heat treat larger parts are not set up to handle ultra-precision small parts.”

Casey and Joe enlisted the help of Rod Beverley to spearhead the company’s preparation for Nadcap accreditation for heat treat.

“Six months ago, we began the difficult process of accreditation, and in June of this year we were successfully Nadcap accredited for heat treating,” Beverley says.

Casey says that customers who machine very small parts that require both heat treat and plating, Nadcap accreditation, can simplify the number of companies in their supply chain and send their parts to his shop.

“A major challenge that is witnessed across the electronics industry is plating coverage on the insides of small heat-treated beryllium copper parts,” he says. “One can have the best plating chemistry in the world, but heat treat scale and parts not cleaned properly prior to heat treat is often a major contributor to this issue.”

In-Process Inspection Validates Cleaning

Casey says that Foresight Finishing has in-process inspection that validates the cleaning of heat-treated components so they don’t go to plating with contaminated ID’s. However, this does not correct the problem — it only identifies it, until now.

“The combination of our small parts plating line, pre-clean process and vacuum furnace provides our platers with a bright, pristine, oxide free surface that eliminates harsh cleaning cycles that can undersize and etch parts,” he says. “Our heat-treating process creates a surface that accepts the plating deposit willingly instead of hampering it.”

Joe Weizel says that, before they opened their plating business in Arizona, both he and Casey worked for many years plating in Minnesota, where they grew up.

“We learned much about the process, and we also knew that one of the key differentiators we could offer our customers over other platers was state of the art technology and processes,” Joe says. “Foresight Finishing’s plating processes and equipment are best-in-class.”

Joe says the prep processing they have instituted prior to plating significantly reduces their turnaround times. When they made the decision to add heat-treating to their business, they applied these same principles.

“Our built-in cleaning processes help to ensure that the parts that we heat treat are free of debris and oils,” Joe says. “When we heat treat and plate a part, our prep and clean process can take 30 minutes. In comparison, if we plate a part that hasn’t been properly cleaned by an outside heat treater, the cleaning process can take hours or even days de-scaling the parts.”

Making the Oven Fit the Parts

The brothers say they did research prior to investing in their heat treat oven to ensure the oven would be the best fit for the type of parts they plate. In their analysis, they determined that they could purchase a vacuum heat treating oven, and learned it could reduce cleaning cycle times by as much as 70%.

“We offer some of the most competitive heat treat prices and turnaround available in the market,” Beverley says. “Our heat treat and hardness testing lot charges are $275 for heat treat and $100 for hardness testing. In the market, our customers have told us that they paid $350 for heat treat and $150 for hardness testing. We also hear from our customers that 2-3 weeks turnaround for their parts to be heat treated is the norm. We are running 24-7, and with the best equipment, so we are able to offer 3-5 day turnaround for heat treating and plating.”

Casey says that with their quality metrics, they are achieving 98.9% on-time delivery and 99.6% quality.

“When our customers bring us their parts for heat treat and plating, they will see many advantages over using two different suppliers, one for heat treat and one for plating,” he says. “We can provide reduced variability in the process, we can control cleanliness throughout both processes, and we can reduce their turnaround times. When you add this to extremely competitive pricing, I think we’ve got an outstanding solution for customers new and old.”

Prior to starting the heat treat division in their company, Joe and Casey solicited colleagues for recommendations on a hire. Mary Triney came highly recommended, and they brought her on-board to get the heat treat division up and running.

“Mary has done an outstanding job, and we are proud to say that through her efforts, we have the best heat treat facility for ultra precision parts around.” Beverley says. “When you add an oven to Nadcap accreditation, it doubles or even triples the accreditation process; it is just that difficult. I think our successful accreditation to Nadcap for heat treat is a testament to both Mary and the company owners’ drive for continuous improvement. I know our customers value what we have put in place to make their jobs just a little more simplified.”

Contact Foresight Finishing at 480-921-0000 or visit foresightfinishing.com