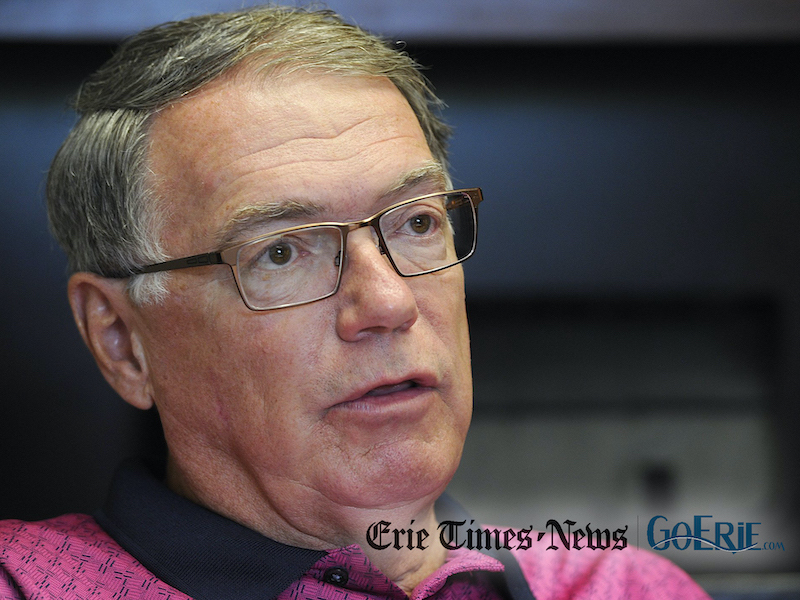

When Dennis Hartwig was looking for a business opportunity to invest in back in 1994, one of his financial advisors told him that getting back into the electroplating business wasn’t a wise move.

“He thought that I was crazy for getting back into this business,” says Hartwig, president and owner of Great Lakes Metal Finishing in Erie, PA.

“He had thought that zinc would eventually be replaced as an inexpensive corrosion resistant material,” says Hartwig, who had spent time in the finishing industry before climbing back in. “Here I am, some 26 years later, and still expanding our capabilities in using zinc and zinc nickel to provide corrosion protection to manufactured parts made throughout the world.”

Hartwig started the company as a result of a partnership with a local wire goods manufacturer that was experiencing quality and delivery issues as a result of their own internal growth. From the first automatic rack line, the GLMF currently has two automatic zinc barrel lines, three automatic zinc rack lines, two automatic passivate lines — one for rack passivate and one for barrel or bulk passivate — and an automatic zinc nickel barrel line.

NEW EQUIPMENT AND LINES

GLMF is currently in the process of installing a new automatic zinc rack line which should be available for “production part approval process” testing by September 2020. The new line will also bring along other changes.

GLMF is currently in the process of installing a new automatic zinc rack line which should be available for “production part approval process” testing by September 2020. The new line will also bring along other changes.

“With this line being completed, we will begin converting one of our older rack zinc lines to an automatic rack zinc nickel line with PPAP testing being planned for late 2020,” says Dave Wachter, GLMF’s general manager and sales manager.

With the growth of the company, GLMF is currently operating under approximately 60,000 square feet and looking to add an additional 20,000 square feet sometime in 2021.

Hartwig says that, being a job shop, their customer base crosses many paths; the largest base of customers covers the following automotive, military, fasteners and wire goods. Their top process are zinc with olive drab, trivalent black, trivalent yellow, hexavalent black and hexavalent yellow, zinc nickel with trivalent black, trivalent clear and hexavalent yellow.

GLMF is currently running two shifts four days per week, with a staff of 35-40. Aside from Hartwig and Wachter, the GLMF team is managed by Scott Flook, the production manager, and David Cadwallader, the technical manager.

STAYING TOP DOG

“Our goal is to provide a quality product, within the required timeline,” says Hartwig. “We want to do it at a price point that meets not only the customers’ requirements, but provides us with a reasonable profit to provide for competitive wages and benefits for our staff ,as well as the necessary funds to allow for the continued growth of GLMF.”

Over 26 years later, Hartwig is very happy he got back into the finishing business.

“What makes us really happy is when are recognized by our peers as a quality metal finishing facility within the metal finishing community,” he says. “We’ll continue to make investments in not only our equipment, but our staff, too, that will allow us to remain a ‘Top Dog’ in our industry.

Visit goglmf.com for more information. Photos reprinted with permission from Times Publishing Company, Erie, PA. Copyright 2020

![Willie Dixon, sorts rods that have just been zinc plated at Great Lakes Metal Finishing Inc. in Erie. [JACK HANRAHAN/ERIE TIMES-NEWS]](/images/images/sp_glmf/p3metal051717_copy.jpg)

![A barrel plater is operated at Great Lakes Metal Finishing Inc. in Erie. [JACK HANRAHAN/ERIE TIMES-NEWS]](/images/images/sp_glmf/p2metal051717_copy.jpg)

![Dana Bell, line operator, prepares auto parts to be plated at Great Lakes Metal Finishing Inc. in Erie. [JACK HANRAHAN/ERIE TIMES-NEWS]](/images/images/sp_glmf/p4metal051717_copy.jpg)

![Scott Flook, left, production manager, George Gore, center, production supervisor, and Dave Cadwallader, plant manager are shown at Great Lakes Metal Finishing Inc. in Erie. [JACK HANRAHAN/ERIE TIMES-NEWS]](/images/images/sp_glmf/p6metal051717_copy.jpg)

![These brackets will be used by automaker Honda for a sunroof assembly. [JACK HANRAHAN/ERIE TIMES-NEWS]](/images/images/sp_glmf/p5metal051717_copy.jpg)