The future is looking ‘bright’ for the team at Technical Plating in Brooklyn Park, Minnesota. In the past two years, they have added an additional bright tin line, a second electroless nickel line, a bright nickel line, another passivation line and another reel-to-reel line, bringing their total to 17 lines.

“At the moment, we are focusing on growth,” says Tyler Thomas, vice president and general manager. “We are bringing on new processes as the market is asking.”

The Thomas family owns the company and is transitioning into its third generation of management with Tyler taking the helm. Technical Plating was founded in 1975 to meet the high demand of tin and nickel plating needs of the growing electronics industry in the Minneapolis area and has grown into one of the largest tin platers in the country.

“We have focused on the telecommunication and battery industry for the past several decades,” says Bryan Thomas, the company president, who has been with Technical Plating since 1983.

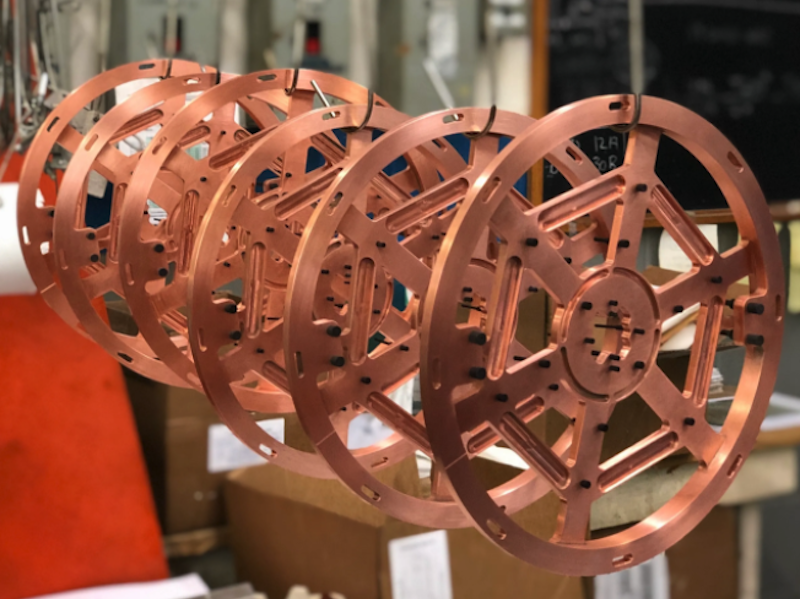

More than 10 Finishes on 17 Plating Lines

The company was started by Jim Thomas in a small shop in Brooklyn Park just outside Minneapolis. Over the years, Technical Plating grew into a 30,000 square foot facility that houses 17 plating lines and more than 10 finishes.

Bryan has been the key factor in the aggressive growth of Technical Plating over the past 30 years. His daily routine centers on R&D and customer service. Tyler has been with Technical Plating since 2013, where he started out racking parts and now oversees daily operations such as finances, certifications and overall business growth.

Tyler sits on the board of the Minnesota Association of Metal Finishing Chapter of the NASF and other small business boards, and holds a bachelor’s degree in finance, accounting and management.

Technical Plating has roughly 20 employees and one shift, but their business has been steady and growing.

“We focus on communication with our customers, and developing relationships with them to attract and retain business,” Tyler says. “The attention to detail, flexibility, and un-matched customer service has been a large factor in our growth.”

Talented Management Team

Kevin Anderson is the operations manager, and has been with Technical Plating since 1988. He started as a plater, and is in charge of scheduling, customer service, and day-to-day operations in the plant. Kevin has extensive tin and electroless nickel plating experience. In his free time Kevin enjoys golfing and fishing.

Verna Keiser is the office manager, and has been with Technical Plating since 2012. She looks after the front office, order processing, accounts payable and receivable, purchasing, customer service and human resources.

Metal Chem, Hawkins and Seacole are some of Technical Plating’s top suppliers

“They go above and beyond with their service and technical knowledge,” Tyler says.

Technical Plating has several environmentally conscious initiatives in place that address all aspects of their business. From their offices to the main floor of the plant, the initiatives help mold their philosophy of operating a high-quality, environmentally-friendly plating company.

Reducing Water and Sewage Usage

Several years ago, the shop collaborated on a water and sewer reduction project with the University of Minnesota’s Minnesota Technical Assistance Program (MnTAP), which is funded by a grant from the Minnesota Office of Environmental Assistance to the University of Minnesota’s School of Public Health.

According to the study, water use at Technical Plating increased from 40,500 to 54,000 gallons per day (gpd). The local sewer authority proposed a one-time sewer access charge (SAC) of $56,000 for the increased water use to help defray future capital costs to accommodate and treat these higher flows.

Technical Plating requested MnTAPs help reduce water use, thus hoping to lower or eliminate the SAC. The agency helped the company explore how to reuse treated effluent for some plating rinses and devised and evaluated an internal rinse system for barrel plating.

To reuse its effluent, the shop installed a sand filter and two holding tanks. One tank was used to recirculate water through the sand filter for one to two hours, and the second tank held the filtered effluent until it was needed on the line. Effluent was reused on one line with no measurable decrease in the quality of parts produced. At the time, the system cost $5,200 to install and cost $800 a year to operate. It saved $3,800 a year in fresh water purchase and sewer fees by eliminating 5,500 gpd [1,375,000 gallons per year (gpy)] of water use. The system also reduced one-time SAC fees by $23,100.

Technical Plating also installed three flow meters on one line’s rinses at a cost of $450. After management gave instructions to limit flows, water use decreased by 5,000 gpd (1,250,000 gpy), saving $4,100 in sewer and water costs and $21,000 in one- time SAC fees.

When the study was completed and all recommendations implemented with the help of MnTAP, the shop reduced water demand by 2,625,000 gpy, saving $7,100 a year plus $44,100 in one-time SAC fees.

Working More Efficiently

Working smarter and being more efficient is one way Tyler Thomas says that Technical Playing will continue to grow.

“I believe we will have a continued focus on growth, continuous improvement, and quality in the coming years,” he says.

Visit https://techplating.com/