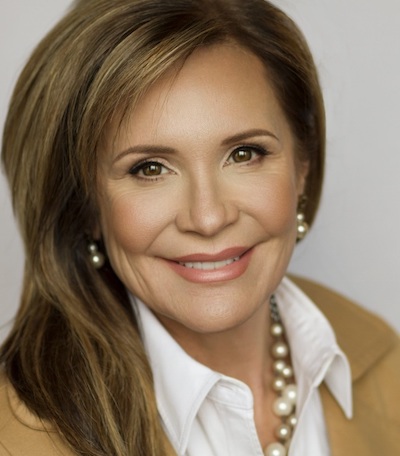

Years ago, Tamea Franco was a typical entrepreneur in Roanoke, Virginia, she spent a lot of time in her basement with numerous buckets of chemicals and sheets of aluminum performing anodizing experiments.

It was the early 1980s, and Franco — now president of Global Metal Finishing — had taken a watchmaking course, and then a metalworking class that included a look at anodizing aluminum. From there she was hooked; in 1987 she started East West DyeCom, which sold aluminum dyes to universities and colleges that had metal art programs.

“My background in horology enabled me to create a market for something that had never existed, which was a product line of colored aluminum sheets, tubes, wire shapes, and components,” Franco says. “I traveled the country, teaching workshops on how to color, form, and join it while peddling my product line to metal artists.”

“My background in horology enabled me to create a market for something that had never existed, which was a product line of colored aluminum sheets, tubes, wire shapes, and components,” Franco says. “I traveled the country, teaching workshops on how to color, form, and join it while peddling my product line to metal artists.”

While GMF today specializes in aluminum and hardcoat anodizing, colorwork for both hexavalent and trivalent chemical conversion coatings, and stainless steel passivation, it’s roots date back to Franco’s original company at East West DyeCom, which quickly became the only nationally recognized distributor and supplier of colored aluminum, but also soon the company morphed into becoming more than a distributor of dyes.

On The Road To Becoming An Anodizer

In 1994, she was commissioned to anodize a large casting for a company that manufactures night vision products. She still remembers the fear she felt when the engineer came to the 2,500-square-foot building she was renting, to ask for help.

“I told him I could not do it,” Franco says. “I explained to him that I knew the concentration of the acid in the anodizing tank, and I knew the 720 rule, and I knew how to measure the output of the amperage of the Lincoln welder I was using for a rectifier, but I could not measure the thickness of the buildup, because I did not have the equipment.”

The engineer then re-framed his question. “Can you insulate the surface?”

The engineer then re-framed his question. “Can you insulate the surface?”

“I said, ‘Yes I can do that,’ and it was at that moment that I jumped on the road to becoming a commercial anodizing company,” says Franco.

For the next 16 years, she continued producing and selling what she calls the “product line,” while fulfilling the service side of the business by providing industrial anodizing to regional OEM’s and machine shops. But serving two vastly different markets was exhausting to her and her team.

“It took deep introspection on my behalf to look myself in the mirror and have a ‘come to Jesus’ meeting to determine the future I wanted to be realized for the company and my employees,” she says. “Immediately, I knew what I needed to do, and it was validated the next day.”

Global Metal Finishing is Born

She went into the shop one day in 2009 and saw the service side of the business shipping work all over the world; they had become an integral partner in the global supply chain.

“It was that ‘aha moment,’” says Franco, who switched gears in the direction of the company and changed the name to Global Metal Finishing, thus fully committing the company’s efforts to the service side of the business.

“It was that ‘aha moment,’” says Franco, who switched gears in the direction of the company and changed the name to Global Metal Finishing, thus fully committing the company’s efforts to the service side of the business.

“It wasn’t easy giving up the revenue from the product line,” she says. “But in hindsight, it was a very wise decision. The next year I purchased three buildings and relocated the full operation.”

But being a job shop means serving all industries that walk through the door, which is what Franco and her team had to do. But while GMF is focusing on companies that are diversified, Franco also realized that those companies want more than just price. The antiquated way of doing business was to beat up a vendor for the rock bottom price, but a sophisticated purchasing system focuses on the supplier’s expertise, quality, technology, and delivery.

And that is what Franco wanted her company to aim for: quality and delivery.

“It is this ‘whole package’ approach that we deliver, and it sets us apart,” she says. “We have found that when we focus on these things, it is easy to agree upon a price. This type of engagement is smooth and satisfying for all parties involved and breeds recognition and respect, it also makes everyone happy.”

The Right People in the Right Seat

Whether GMF is processing defense work or a medical device, she sells everyone in the company that touches the job knows that the people they serve appreciate what they bring to their table, and it naturally makes her team bend over backward for the customer.

Whether GMF is processing defense work or a medical device, she sells everyone in the company that touches the job knows that the people they serve appreciate what they bring to their table, and it naturally makes her team bend over backward for the customer.

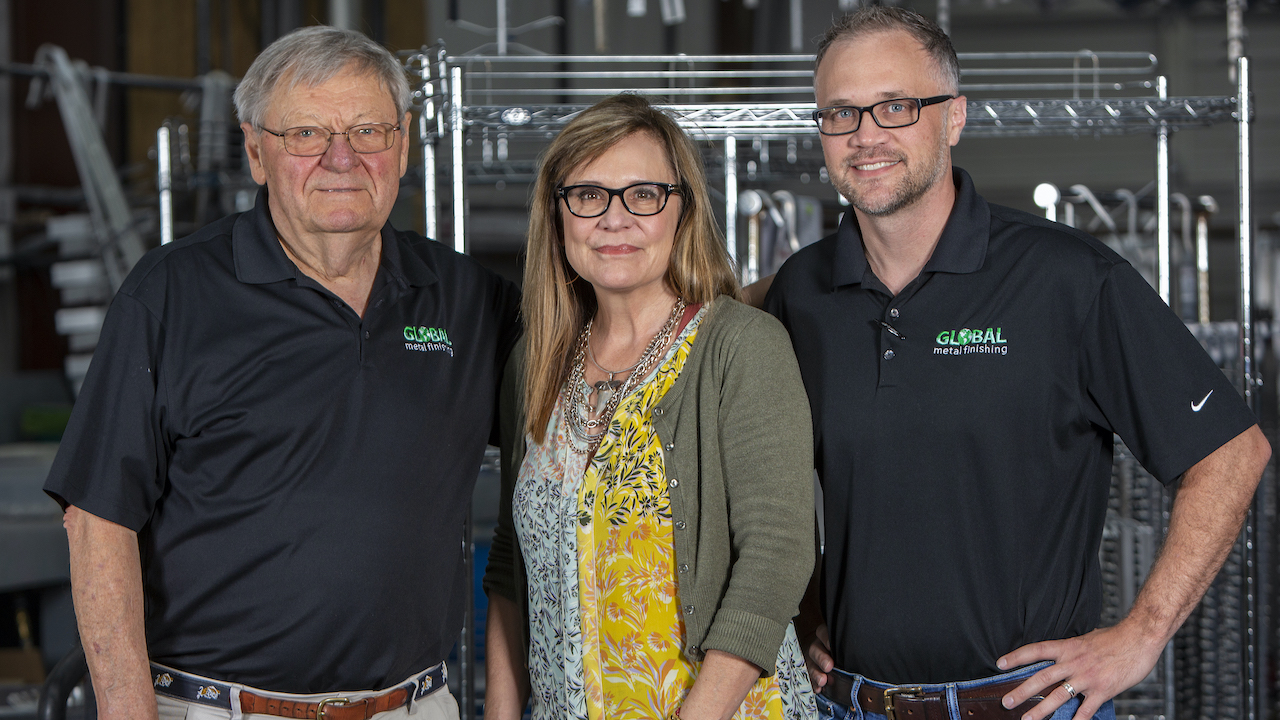

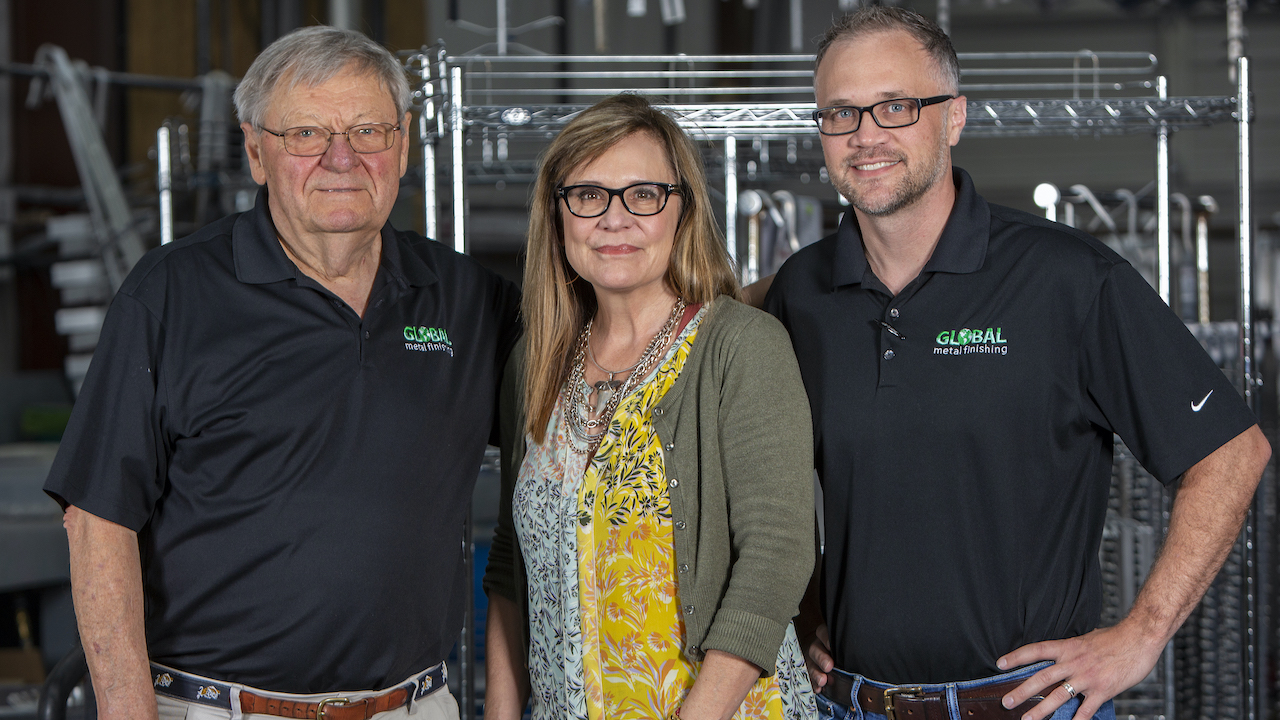

Three years ago, Franco brought on Al Vasiliauskas, a retired Naval engineer and business executive, to be GMF’s chief operating officer. Franco is a big believer in the book Good to Great by Jim Collins, who speaks about not only getting the right people on the bus (the company) but also about getting them in the right seat (position).

“That is exactly what Al did for Global Metal Finishing,” Franco says. “He guided us towards becoming a more data-driven company, allowing us to solve problems less emotionally and more logically. His process optimization approach eliminated chaos and mediocracy. It took him less than 12 months to get the management team on the bus and in the right seat.”

While Franco focuses on increasing the company’s market share in their region along the East Coast, the management team is focusing on the GMF’s strengths and setting goals, while also receiving input from all the people on the shop floor.

Franco says the culture of a company is so critical to GMF’s success.

“We have successfully created a conscious, inclusive workplace that is healthy,” she says. “It’s amazing and rewarding to see how everyone is involved in developing communication systems to take care of the customer needs, while also managing the complexity and speed of which we are required to work.

Growing and Enriching Employees

“Two years ago, we outgrew the space for masking and racking and moved that operation into another building,” she says. “We’ve continued to make capital investments this year, even though there are so many unknowns in manufacturing.”

GMF’s top suppliers are Brenntag Mid-South with Jim Collins and Will Fisher as their wastewater treatment suppliers. They also utilize E2 Shop System, with guidance from Karine Henschen and Dan Labulis to support their ERP system.

Franco says the most exciting supplier they have brought on this year is Jason Ray and his team at Paperless Parts, which will be integrated with their ERP software to create a seamless, secure, nesting for all the data required in their quoting process.

“The speed at which we can now respond to the marketplace is phenomenal,” she says.

Franco — who got married this year to Norman Harris just before the pandemic hit — admits that owning a finishing and coating operation may not have been her career plan from the outset, but she is enjoying tremendously the work that she and her GMF team do each day for manufacturing operations.

“What makes me the happiest is when our employees take care of our customers by showing up professionally with the drive to succeed and a desire to ask why,” she says. “They know that they not only represent Global Metal Finishing, but they also represent the finishing and coating industry. It thrills me to see how smart these young people are and how eager they are to learn.”

Visit globalmetalfinishing.com