A walk through the sprawling 175,000-square-foot campus that is Durable Industrial Finishing Co. (DIFCO) in Tucker, Georgia, will tell you all that you need to know about how automated the operations are at this 60-year-old finishing operation.

But to David Henderson, president and one of the owners of DIFCO, some things just can’t be automated, and that includes the human that answers the phone when customers call the company.

But to David Henderson, president and one of the owners of DIFCO, some things just can’t be automated, and that includes the human that answers the phone when customers call the company.

“That person will do all they can to help you,” says Henderson, whose father in law was one of the founders of the business in 1960. “We constantly hear that people like working with us.”

The switchboard aside, automation has been the key to the growth of DIFCO over the last six decades. Henderson and his wife Patti along with Terri Boyce, and Chris Henderson, who is vice president of operations, own the business.

The management team also consists of Alan Morton, vice president of production and logistics, and Art Wormet, executive director of sales and marketing.

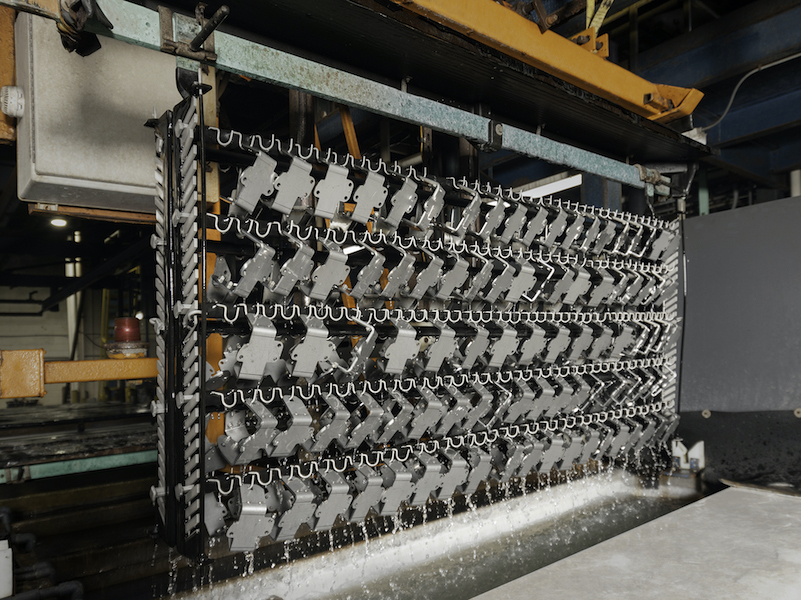

Henderson says DIFCO is constantly building and improving their equipment. Its newest process line is a highly automated zinc flake dip spin system, which compliments the existing processes featuring zinc, zinc-nickel, electroless nickel, manganese phosphate, zinc phosphate, chemical film, and passivation.

Expanding Its Zinc Flake Dip Spin Capabilities

At left, Alan Morton is Vice President of Production & Logistics, along with Chris Henderson, Vice President of Operations and Owner.In fact, DIFCO is planning to expand its zinc flake dip spin capabilities because of its superior corrosion protection properties offered by the coating. The facility operates two expandable shifts with 70 employees 24 hours per day.

At left, Alan Morton is Vice President of Production & Logistics, along with Chris Henderson, Vice President of Operations and Owner.In fact, DIFCO is planning to expand its zinc flake dip spin capabilities because of its superior corrosion protection properties offered by the coating. The facility operates two expandable shifts with 70 employees 24 hours per day.

“We have a very talented team of dedicated managers and fabricators,” Henderson says. “One of the major contributors to our success has been its ability to build, automate, customize, and maintain our own equipment.”

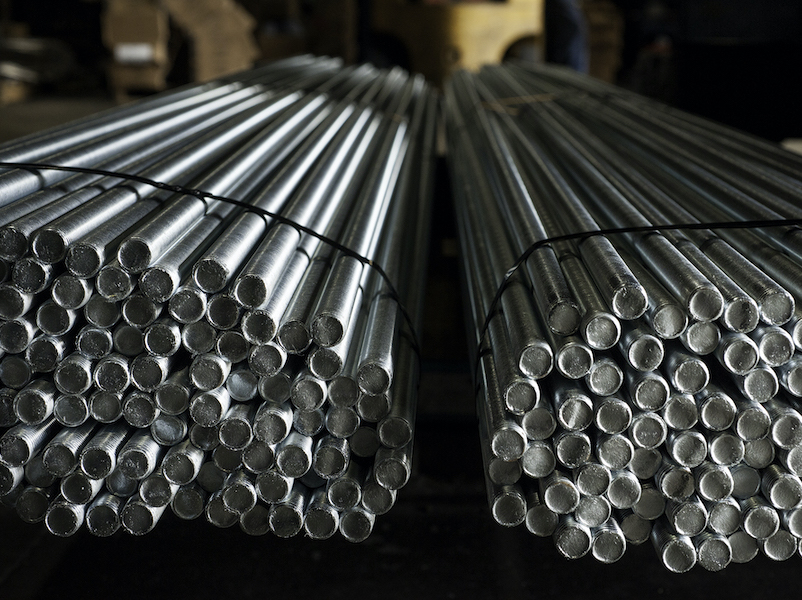

DIFCO provides metal-finishing services to hundreds of manufacturers and distributors. These customers represent a variety of industries including aerospace, agricultural equipment, automotive components, construction products, Department of Defense components, electrical/electronic, fastener, firearm, heavy equipment components, lawn and garden, material handling, outdoor power equipment, telecommunications, transportation products, and wire goods.

DIFCO is supported by many suppliers, all of whom have been carefully and routinely evaluated to gain certification to be on their approved supplier list. Some of our top suppliers for proprietary chemistry include Atotech, DuBois, MacDermid Enthone Industrial Solutions, NOF Metal Coatings, and Pavco, which is distributed and serviced by Plating Specialists, Inc.

“We are firm believers in the redundancy of equipment which minimizes any downtime allowing us to meet or exceed our customers’ delivery requirements,” Henderson says. “We have also forged strong relationships with our chemical suppliers and other vendors who provide us with excellent technical support and on-site assistance as needed.”

Founding in 1960

The company was founded in 1960 as Dixie Industrial Finishing Co. by Richard Russell, Milton Jones, and several other investors. At the time, Russell was selling plating equipment and chemistry in the Southeast, and Jones was working at Simmons Plating Works. They started operations in downtown Atlanta as a metal finishing job shop servicing a diversified customer base. They quickly established their reputation in the early years as a quality plater based on stringent quality requirements from its aerospace and U.S. Department of Defense customers.

The company was founded in 1960 as Dixie Industrial Finishing Co. by Richard Russell, Milton Jones, and several other investors. At the time, Russell was selling plating equipment and chemistry in the Southeast, and Jones was working at Simmons Plating Works. They started operations in downtown Atlanta as a metal finishing job shop servicing a diversified customer base. They quickly established their reputation in the early years as a quality plater based on stringent quality requirements from its aerospace and U.S. Department of Defense customers.

Years later, Russell became the sole owner of the company, and in 1977 he moved its operations to its present-day location in Tucker, about 10 miles from downtown Atlanta. Shortly thereafter, Russell’s son-in-law, David Henderson, joined the company to lead the maintenance department and start DIFCO down the path of building its own equipment, which it continues today.

Henderson became president in the 1990s and ownership has remained within the family. But 2020 marked a major milestone when the company changed its name to Durable Industrial Finishing Co., and kept the DIFCO abbreviation, and even adopted it as a trade name.

Far from their small beginnings in the Southeast, DIFCO’s coatings can now be found on manufactured parts across the United States as well as in other countries. The owners believe the new name reflects not only the durability of their company as a leader in the metal finishing industry, but also their finishing and coatings provide durability to the various industries they serve.

Chris Henderson says a major contributor to DIFCO’s success has been its commitment to measurement and analysis. DIFCO strongly believes in the adage “if you can’t measure it then you can’t manage it.” These qualities, combined with a family-type atmosphere, have contributed towards an extremely low turnover rate amongst employees.

“We are proud to have a high number of employees with more than 20 years of service,” Chris says. “It’s a record that helps drive consistent results.”

Automation and Improved Efficiencies

For years, DIFCO has been automating and improving the efficiencies of its equipment resulting in a significant amount of excess capacity. Recently, the company hired Wormet to help fill that capacity. He brings a wealth of experience as a former vice president and managing director of another large plating operation, as well as president of his own consulting firm.

For years, DIFCO has been automating and improving the efficiencies of its equipment resulting in a significant amount of excess capacity. Recently, the company hired Wormet to help fill that capacity. He brings a wealth of experience as a former vice president and managing director of another large plating operation, as well as president of his own consulting firm.

“We feel that Art’s expertise, coupled with our ability to build and customize equipment, will give us the edge needed to meet the finishing demands of the market,” David Henderson says.

As a faith-based business, Henderson says DIFCO has always tried to run their business by treating others the way we would like to be treated and being a good steward of the resources with which they have been entrusted. The company was honored as a recipient of the Manufacturer of the Year Award in the Small Business category in Georgia, which included a presentation by the governor.

“We like to say that we make our customers’ parts look better, work better and last longer,” Henderson says. “Manufacturers of steel parts know that their parts would not last long without the metal finishing industry. From that standpoint, we take pride in providing a valuable service to U.S. manufacturing and, ultimately, consumers from all walks of life and various geographical regions.”

Visit https://difco.us.com/