In the finishing world, no one likes friction when it comes to the corrosion protection of their parts. For William Howard, Jr. of Houston Plating and Coatings, other types of friction rub him the wrong way, too, especially when it comes to logistics.

William Howard Jr.“We’re the frictionless finisher,” says Howard, primary owner and Chief Executive Officer of HP&C in Texas, which bills itself as a one-stop-shop for customers’ corrosion and wear protection, mostly in the gas and oil industry and specializing in electroless nickel plating finishes.

William Howard Jr.“We’re the frictionless finisher,” says Howard, primary owner and Chief Executive Officer of HP&C in Texas, which bills itself as a one-stop-shop for customers’ corrosion and wear protection, mostly in the gas and oil industry and specializing in electroless nickel plating finishes.

Howard says he considers procedural or logistical steps that inhibit or slow down the completion of the manufacturing process as points of friction. But since taking ownership in 2003 — and with a background in the accounting industry — Howard has redefined HPC’s supply chain-based approach to delivering services. His focus has been to undertake steps designed to remove points of friction, including such things as transportation delays or incomplete and inconsistent PO instructions.

“We have a supply chain approach to delivering services that integrate with our clients’ production schedules and a primary focus on quality and turn-around times,” says Howard, whose company has 150 employees and annually makes the list of top facilities in the plating industry.

Commitment to Quality and Turn-Around

Eric TurnerEric Turner, an HPC owner and Chief Operating Officer says the company’s commitment to quality and turn-around has been the primary driver for new business.

Eric TurnerEric Turner, an HPC owner and Chief Operating Officer says the company’s commitment to quality and turn-around has been the primary driver for new business.

“Devising unique and creative solutions to difficult plating, wear, and other corrosion protection services have also been keys to developing business,” Turner says. “Especially in the power generation, firearms, and industrial gas industries, for instance.”

Howard says the company’s continual expansion of facilities, services, and capabilities demonstrates evidence of its commitment to productivity, quality control, and capacity to ensure some of the fastest turn-around times in the industry. He and Turner — along with Alberto Landois, another owner and vice president of operations — have streamlined administrative processes, detailed specifications review, remote satellite operations, and scheduled pickup and delivery routes to help expedite clients’ corrosion and wear protection requirements.

“By utilizing supply chain-based solutions and a commitment to innovation and quality, we make HP&C the easiest — and frictionless — company with which to do business,” Landois says.

As an example of their innovation and quality, Turner points to a Pennsylvania power generation company that came to HP&C asking them to plate parts for which they were having as high as a 75% failure rate. Using some of HP&C’s proprietary nickel and EN processes and their years of experience, Landois and his team developed new processes and equipment that reduced the failure rates and eventually produced a 100% success rate.

Proprietary Electroless Nickel Process Ni-Side

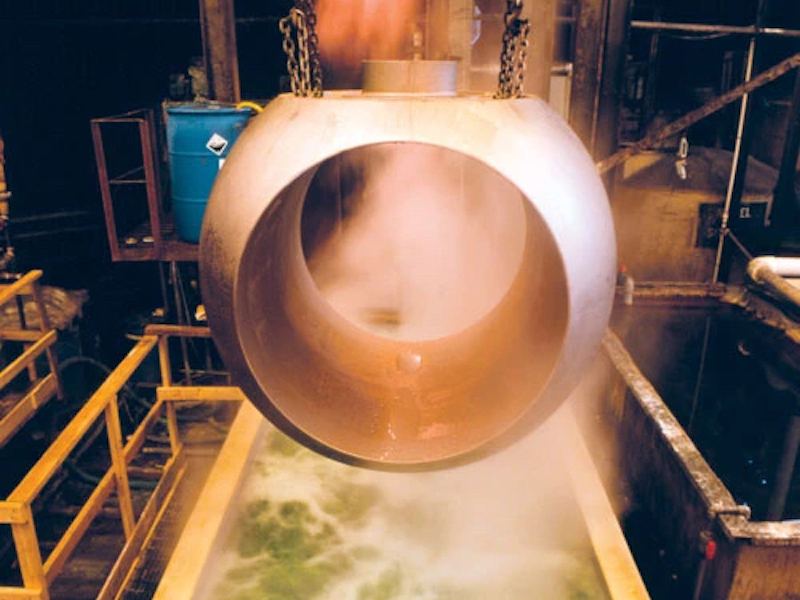

Alberto LandoisAs an example of the firm’s innovative solutions, Turner says “the industrial gas industry needs nickel plating to prevent contamination of gases,” but producing high-pressure nickel plated cylinders used to store and transport gasses has not been scalable, so very few could be provided to the industry. Additionally, geometry of the cylinder was not compatible with the standard plating process, so an entirely new approach was required”

Alberto LandoisAs an example of the firm’s innovative solutions, Turner says “the industrial gas industry needs nickel plating to prevent contamination of gases,” but producing high-pressure nickel plated cylinders used to store and transport gasses has not been scalable, so very few could be provided to the industry. Additionally, geometry of the cylinder was not compatible with the standard plating process, so an entirely new approach was required”

Landois says interaction with carbon steel degrades the gasses stored and transported in high-pressure gas cylinders, but electroless nickel plating provides a barrier between the gasses and the steel, thus eliminating the degradation and consequent gas contamination. And because of the inherent difficulties of plating cylinders with standard plating processes, Landois says the overall production of plated cylinders has been very limited, which also made the cost prohibitively expensive.

HP&C, though, has developed and has pending patents on several new processes and equipment that can supply significant numbers of nickel plated cylinders to the industry at a significantly lower cost. One of those is a proprietary electroless nickel process — which HP&C calls “Ni-Side” achieves 99.99% coverage with a uniformly thin layer of plated nickel.

Howard says HP&C has some of the largest EN tanks in the industry and can dedicate a full production line to the new cylinder plating processes. “We can plate multiple cylinders simultaneously; therefore, a large number of cylinders can be completed in a relatively short period of time,” he says. “And at a substantially lower cost than with current methods.”

‘Game Changer’ for the Industrial Gas Market

HP&C announced a new process to apply electroless nickel plating to high-pressure gas cylinders in volume, called Ni-Side.Ashley Madray, President of Gas Innovations in LaPorte, Texas, one of the largest distributors of industrial gasses in the country, welcomed the new process.

HP&C announced a new process to apply electroless nickel plating to high-pressure gas cylinders in volume, called Ni-Side.Ashley Madray, President of Gas Innovations in LaPorte, Texas, one of the largest distributors of industrial gasses in the country, welcomed the new process.

“Until now, large quantities of cylinders made of carbon steel could not be utilized to store or transport industrial gases because of the time and cost required to ‘plate’ them,” Madray says. “This new process and volume capabilities will allow for many more applications and improved availability.”

Unacceptable contamination of the gasses — which produces significant inefficiencies — may now be improved significantly, according to Madray

“This should be a game-changer for the industrial gas market,” he says.

HP&C was started by Joe Crutchfield in 1988 and originally offered only electroless nickel plating services, but additional services were added over the years to support the goal of becoming a ‘one-stop-shop for corrosion and wear prevention services.

A graduate of Rice University, Howard spent 30 years at Arthur Andersen, becoming a tax partner at the Big Eight accounting firm before leaving in 2000. In 2003, working with Main Street Capital, he assembled a team to acquire and develop a growth plan for Houston Plating Co., subsequently renamed Houston Plating & Coatings.

Reputation for Quality and On-Time Dependability

As CEO, Howard has utilized his previous business experience to institute financial, sales, and production processes that have enhanced the HP&C reputation for quality and on-time dependability, which have produced dramatic growth over the years.

Using his background in business and his expertise in supply chain management, revenue went from $6.5 million in his first year in 2003 to $8.8 million in 2004 and more than $40 million by 2014.

While completing his B.A. degree at the University of Houston/Clear Lake, Turner began working part-time in 2001 at HPC as a forklift operator. After completing the company’s training program, he earned his certification as a Level 3 NACE Certified Coating Inspector, resulting in his promotion to Quality Manager.

In 2014 Turner was promoted to vice president, and in 2016 he was appointed COO with the goal of having HP&C recognized as the premier provider of plating and coating services in the nation.

As head of production, Landois is charged with making sure that client work is done on schedule, on budget, and to the quality standards set by HP&C and expected by the company’s clients. He oversees staffing schedules and training and monitors the operation and efficiency of all production lines. Because meeting production schedules must align with quality control, Landois works closely with HP&C’s QC department to ensure each stage of production conforms to industry specs and HP&C’s standards.

After earning his BA degree in Mexico, Landois emigrated to the U.S., subsequently becoming a U.S. citizen. He joined HP&C in 1989 and began learning the plating and coating business from the ground up. In 1994 he was made 2nd shift supervisor and, in 1999, he was promoted to supervisor over the EN and phosphate departments. Recognizing his management capabilities, when the new ownership team took over in 2004, Landois was promoted to vice president of operations.

EN, SBN/QPQ, Phosphate, and Passivation

The company offers a broad range of plating and coating services, including electroless nickel plating, SBN/QPQ (salt bath nitriding), phosphate, passivation, and a wide variety of spray coatings, including Xylan, Hempel, Molys, and Epoxies.

The company offers a broad range of plating and coating services, including electroless nickel plating, SBN/QPQ (salt bath nitriding), phosphate, passivation, and a wide variety of spray coatings, including Xylan, Hempel, Molys, and Epoxies.

Coventya is the main supplier of their nickel chemicals, and Whitford supplies the xylan paint. Parker Trutec works with HP&C on the SBN/QPQ processes.

HP&C has a facility in South Houston and in Humble, which recently added a 25-ton lift capacity and a dedicated epoxy coating facility. To better serve its growing list of Louisiana customers, HP&C operates a scheduled pickup and delivery service to and from the state at their pickup location in Broussard, Louisiana, on Wednesday mornings. The finished parts can be picked up the following Wednesday at the same location, with no transportation charges incurred.

In addition to the ISO 9001:2015 Certification, HP&C is one of the few plating and coating companies in the Houston-area that employs a Level III NACE Certified Coating Inspector on staff, as well as other NACE certified inspectors at both locations. NACE certified inspectors, for instance, are required for NORSOK epoxy coating applications.

Energy Makes Up 90% of Business

Howard says that, historically, the energy industry has been the primary customer base for HP&C, accounting for over 90% of the business.

“We expect that in the relative near future, industries other than energy, particularly the industrial gas industry, will become a significant part of our customer base,” he says.

The HP&C team says that corrosion protection for the emerging renewables industry — particularly offshore wind farms — opens potentially significant new areas for business development for the company and there is also a potentially huge market for inexpensive nickel-plated parts to replace expensive parts made out of stainless steel in many industries other than energy.

He is confident that HP&C can compete with any sized finishing and coating facility because of its production efficiencies and knowledge.

“We are a relatively small company,” Howard says. “But our reputation for quality, turnaround, and unique solutions to finishing needs have brought companies to HP&C from all over the country and Canada.”