When it comes to wooing prospective customers, most finishing and coating operations don’t usually start by showcasing their fixturing capabilities, but not U.S. Chrome.

Racks and fixtures are created in-house.The company has five locations spread across Connecticut, Illinois, New York, Ohio and Wisconsin, and takes pride in how their unique fixturing approach has been able to win over customers and finish parts when others had trouble.

Racks and fixtures are created in-house.The company has five locations spread across Connecticut, Illinois, New York, Ohio and Wisconsin, and takes pride in how their unique fixturing approach has been able to win over customers and finish parts when others had trouble.

In fact, Bob Reath, Owner and Chairman of the Board, says they recently had a group from the National Aeronautics and Space Administration (NASA) and its Jet Propulsion Laboratory pay them a visit after the NASA engineers had difficulty in having a part plated successfully by several other facilities.

“During a visit, we allowed them to evaluate our fixturing to demonstrate how we go about plating the tougher applications,” Reath says. “They told us we were at a level above the other platers they had worked with and that we were the type of chrome plater they need to be working with going forward. Feedback like this is what pushes us forward.”

Specialists in Hard Chromium and Plating Alternatives

As its name implies, U.S. Chrome specializes in hard chromium plating, which is often referred to as engineering chromium. But they are also experts in chromium plating alternatives, electroless nickel, and electrolytic nickel plating.

They specialize in various industries, including aerospace, agriculture, alternative energy, firearms, heavy industry, FAA repair, food, motorsports, oil and gas, military, and defense.

They employ about 110 employees over their five separate locations, which runs either extended single shifts to two shifts. Several years ago, the company started USC Technologies in Stratford, CT., to innovate hard chrome plating alternatives, including environmentally-friendly chrome alternative coatings. They currently market NiCom (Nikasil) and TriCom, as well as several electroless nickel and other green coatings

They employ about 110 employees over their five separate locations, which runs either extended single shifts to two shifts. Several years ago, the company started USC Technologies in Stratford, CT., to innovate hard chrome plating alternatives, including environmentally-friendly chrome alternative coatings. They currently market NiCom (Nikasil) and TriCom, as well as several electroless nickel and other green coatings

Although its more than 70 years old, U.S. Chrome CEO John Carpenter says, the company has been upgrading the infrastructure in all its facilities, including new building additions, complete electrical upgrades and expansions, ventilation upgrades and expansions, and heating and related pressure equalization equipment upgrades. They have also added new electroless nickel and electrolytic nickel plating capacities and new rectification upgrades and expansions.

Developing High-Temp Wear and Oxidation Resistant Coatings

“We are continuously growing our alternative coatings business with our NiCom and TriCom wear and corrosion-resistant coatings and establishing an alternative decorative chrome coating process,” Carpenter says. “Our R&D is also in the process of developing high-temperature wear and oxidation-resistant electrodeposited coatings. We are always looking for opportunities to provide additional service offerings.”

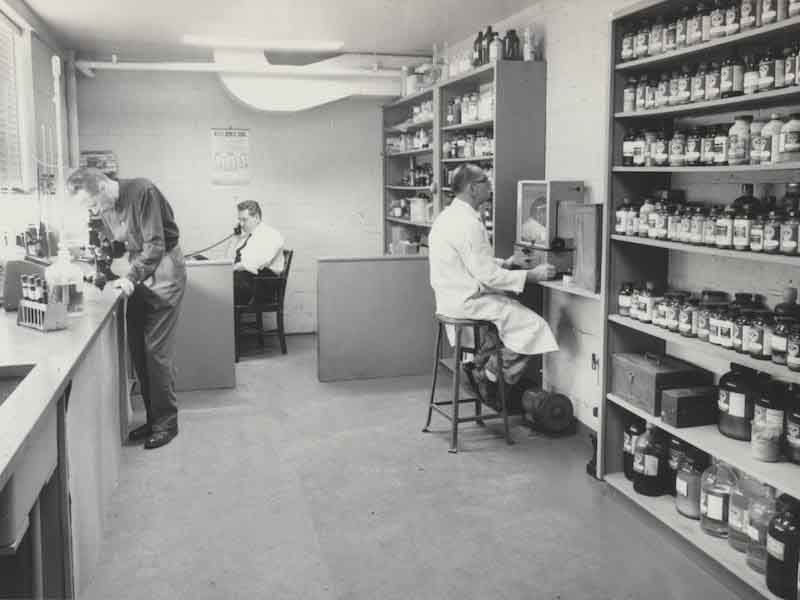

Quality Control in 1959.The history of U.S. Chrome dates back to the 1940s with a predecessor company, Superior Plating, which had additional satellite plants that went by the name Tibon Plating). Superior Plating was started by Reath’s father, Roger, and another partner in 1940. When Roger passed away, Bob split the company 50/50 from the partner to form U.S. Chrome Corporation in 1980.

Quality Control in 1959.The history of U.S. Chrome dates back to the 1940s with a predecessor company, Superior Plating, which had additional satellite plants that went by the name Tibon Plating). Superior Plating was started by Reath’s father, Roger, and another partner in 1940. When Roger passed away, Bob split the company 50/50 from the partner to form U.S. Chrome Corporation in 1980.

U.S. Chrome operates with a small corporate team that works closely with each of their five operating plant managers: Mike Reath in CT; Carlos Adaes in IL; Mike Klotzbach in NY; Greg Santo in OH; Ginger Reath in WI; and Marc Garofalo at USC Technologies.

Mike Reath is Bob’s son, who in addition to being the CT General Manger, is also the company President. Chrissy (Reath) Green is Bob’s daughter who helps in the corporate office with HR. Ginger is his daughter-in-law, who recently became the WI General Manager. She took over those duties after her husband and Bob’s oldest son, Scott, unfortunately and unexpectedly passed away in 2020.

Customer-Oriented Company

Aside from Carpenter, other senior leadership includes Corporate Chief Financial Officer Jeff Boisvert, Al Kertesz and Jon Miller in Corporate Sales, Chris Berlinski, who leads their Corporate Marketing efforts, and Chrissy Green, who helps manage the company HR function.

Bob Reath says being a customer-oriented company helps them strives for complete customer satisfaction, as well as a commitment to quality. Three of their locations have Nadcap accreditation for aerospace components, and one is ISO 9000 accredited.

Bob Reath says being a customer-oriented company helps them strives for complete customer satisfaction, as well as a commitment to quality. Three of their locations have Nadcap accreditation for aerospace components, and one is ISO 9000 accredited.

“We form long-standing partnerships, so our customers feel as though we are an extension of their company,” he says. “We take on the hardest applications and love the challenge of meeting the tough demands that come as part of the many essential business supply chains we serve.”

Coventya, Scrubair, Kraft Power, Process Technologies, Aldonex, Acculabs, Flowking, and PKG Equipment are some of the major suppliers that U.S. Chrome partners with to deliver the quality and service that their customers expect.

Carpenter says the company’s strength is its people, who care very much about delivering customer satisfaction.

‘Care Immensely About Their People’

“We have a strong management team that is united in achieving success, continued growth, and our vision for the future,” he says. “We care immensely about the people who have devoted their lives to working for U.S. Chrome, and we have maintained a very low turnover rate. Although we have turned the company over to a much younger group, we also have many employees that still work for us with up to 60 years of service and counting.”

Bob Reath says the secret to their success is not something all that hidden.

Bob Reath says the secret to their success is not something all that hidden.

“It’s pretty simple,” he says. “We care about our customer’s problems and do everything we can to make their business better. In turn, our customers have truly become our most vocal advocates.”

The satisfaction is when U.S. Chrome hears from one of its customers about how they solved a problem and were able to finish various complex parts.

“Every time a customer expresses their gratitude and appreciation for our services, every time a customer gives positive feedback about interactions with our staff and every time we post winning metrics,” Reath says. “That’s when we know we are having a good day.”

Visit https://www.uschrome.com