Astro Electroplating in Bay Shore, New York on Long Island has always had a knack for being a step or two ahead of the trends when it comes to its finishing lines.

Back in 2005, Astro identified a growing trend in the industry for a satin nickel-plated finish and added a tank to the existing fully-automated plating line that same year.

Back in 2005, Astro identified a growing trend in the industry for a satin nickel-plated finish and added a tank to the existing fully-automated plating line that same year.

In 2016, company president Neil Weinstein says they added a second satin nickel plating tank to meet the ever-growing demands from their customers for various satin nickel finishes. And in 2020, Astro expanded its testing capabilities by installing a copper accelerated salt spray (CASS) chamber for corrosion testing, as well as a pull tester for adhesion.

“We increased our thermal cycle capacity as well,” Weinstein says.

Expansion Into Trivalent Chrome

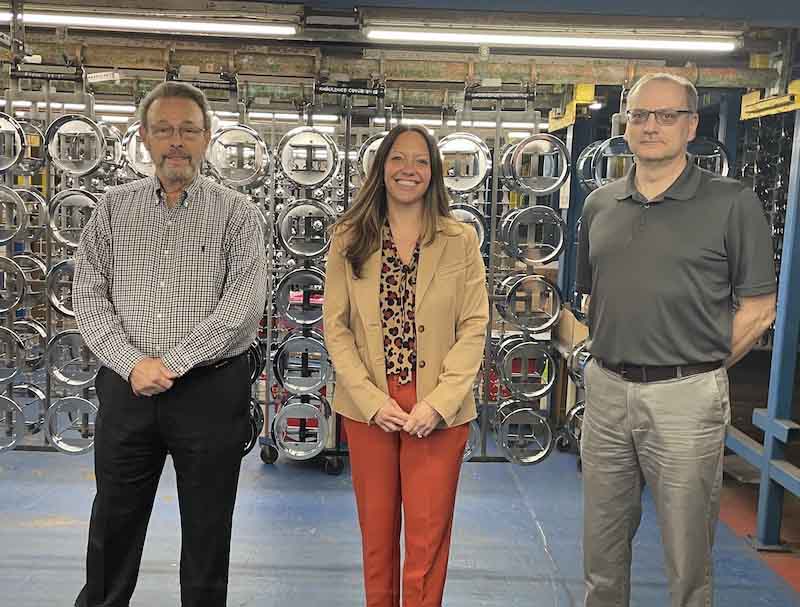

Moving forward, Weinstein and John Jodoin, Astro’s General Manager, say they now see a need to expand into trivalent chrome, and they have been preparing to install this process in their existing line.

“We have also discussed other technologies like paint on chrome and vacuum metallization,” Jodoin says. “That would allow us to increase our support to current customers and service new ones.”

But perhaps Astro Electroplating’s most important addition recently has been bringing on Chrissy Pullara as Chief Operating Officer and Vice President of Quality and Business Development.

Pullara was most recently at MacDermid Enthone Industrial Solutions, where she was Decorative Business Development and Product Manager for the Americas for the chemical supplier.

Wrapped around a two-year stint as a high school chemistry teacher, Pullara spent more than 20 years in the finishing industry with MEIS, which included helping to roll out some of the most advanced chemistries in the industry, as well as working inside some of the top plating facilities in North America.

Extremely Difficult Decision

“Leaving MacDermid Enthone was an extremely difficult decision for me to make,” she says. “I started my career at MacDermid at 22 years old; I was a baby, right out of college. It quickly became my home, my family. I have so many great experiences from my 20-year tenure there and genuinely love the people I worked with.”

“Leaving MacDermid Enthone was an extremely difficult decision for me to make,” she says. “I started my career at MacDermid at 22 years old; I was a baby, right out of college. It quickly became my home, my family. I have so many great experiences from my 20-year tenure there and genuinely love the people I worked with.”

While the management team at Astro had long since identified her as a critical factor in shaping the future of the company and bringing them to the next level, Pullara says the opportunity to join Astro Electroplating came about rather unexpectedly for her. She lives close to the shop, and with the change in travel due to COVID, she was visiting them more frequently since she wasn’t flying all over the country. During a few of her visits, members of the Astro team mentioned that she should come work for them.

“I honestly didn’t take them seriously,” Pullara says. “However, one day, they told me they weren’t kidding, and we got to talking, and well, I guess you could say the rest is history.”

She says the leap to Astro was a big one for her and was an opportunity that she felt she couldn’t pass up.

“While it was bittersweet for me to leave MacDermid Enthone, I’m fortunate enough to still be able to work with so many of my old colleagues,” Pullara says. “They can’t get rid of me that easily.”

Need For Plating-On-Plastics

Astro Electroplating began in 1968, when childhood friends Weinstein and Leonard Seid saw a growing need for plating-on-plastics and purchased DJL Electroplating located in Farmingdale, NY. They changed the name to Astro Electroplating and used Weinstein’s expertise in chemical engineering coupled with Seid’s sales experience to grow the company to be a trusted and recognized leader in the plating-on-plastics industry.

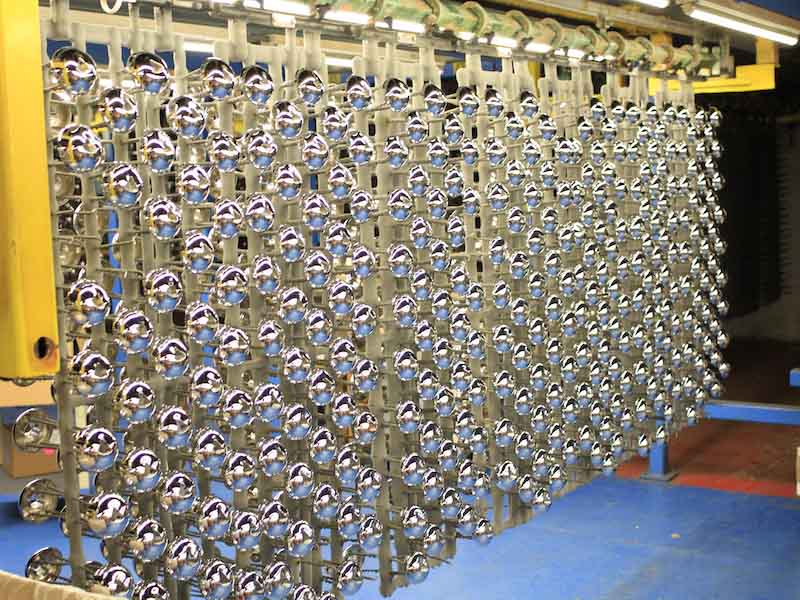

“Satin and bright chrome are our bread and butter,” Weinstein says. “We plate these finishes on a wide variety of plastic materials and grades, including ABS, PC/ABS, and 2-shot molds.”

The shop finds itself plating in various industries, including automotive, communications, computer equipment, construction hardware, cosmetic packaging, electrical components, furniture, household appliance, medical, motorcycle/bicycle, pharmaceutical, and recreational vehicles.

Astro Electroplating has 36 employees running one shift a day. Interestingly, 65% of Astro’s employees are women.

“We are extremely proud of this statistic,” Pullara says. “And we hope that it encourages more young women and girls to pursue educations and careers in STEM.”

New Owners Support Goals

In 2019, Astro was purchased by Zynik Corporation, an investment group that specializes in identifying under-performing opportunities in areas such as banking, health/wellness, service industries, technology, resources, and manufacturing.

In 2019, Astro was purchased by Zynik Corporation, an investment group that specializes in identifying under-performing opportunities in areas such as banking, health/wellness, service industries, technology, resources, and manufacturing.

Weinstein says the new owners have helped to support some of their most recent personnel and industry goals and initiatives.

“We have a talented new management team and are working closely with our sister company, Armada Toolworks, to expand our footprint in the automotive industry,” he says. “The opportunity for growth is really inspiring.”

Armada is a full-service, high-quality manufacturer and supplier to the automotive industry and provides engineered automotive assemblies and components to customers worldwide. Zynik also owns Aarkel Tool and Die, Cottam Diecasting, and Platinum Tool Group, among others.

Gaining Additional Automotive Approvals

With Zynik’s support, Astro Electroplating has been working diligently to gain additional automotive approvals and expects to finalize those in the second quarter of 2021.

“These approvals will mark another significant point in Astro’s history and will elevate not only our capabilities but our reputation,” Pullara says. “It is extremely exciting to be a part of.”

Astro Electroplating has made the journey over the past 40+ years with the help of many talented and responsive suppliers.

MacDermid Enthone and Gilbert & Jones have been long-time chemical suppliers to Astro, and they have also worked with Tilton Rack and Basket for many years as their rack supplier. CDI is a plating equipment supplier that they rely on heavily, Weinstein says.

They will continue to pride themselves on the quality and flexibility that they provide to their customers, and Weinstein believes these attributes have allowed them to build strong, long-lasting relationships with their customers.

“We also try to be as cost-competitive as we possibly can,” Weinstein says. “Operating lean and extremely focused has allowed for these benefits to become a reality for our customers.”