To meet growing demand and better serve new markets, Pioneer Metal Finishing is expanding capabilities for its proprietary Optical Black™ finish.

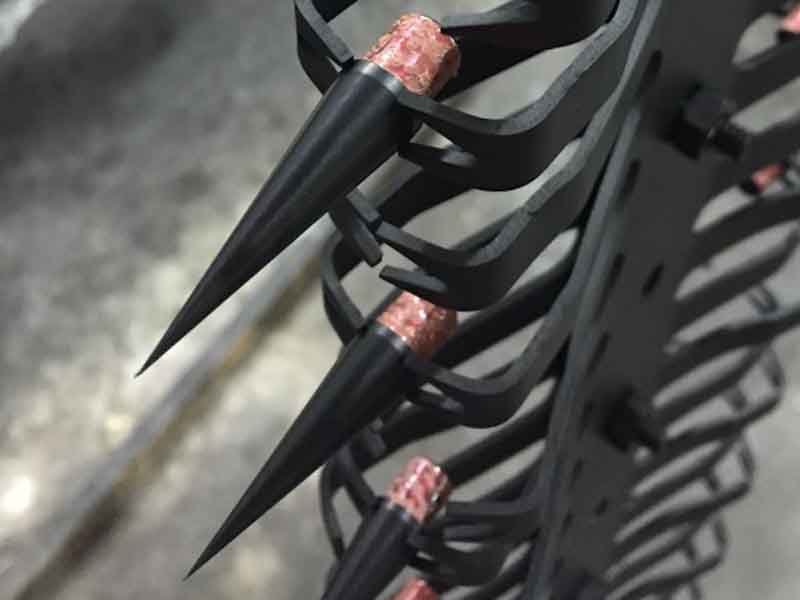

Carlos MillerCarlos Miller, Pioneer’s Vice President of Aerospace and Defense, says Optical Black’s low reflectivity offers many advantages over standard black anodize finishes for rigorous applications including satellite telescopes, military guidance systems, firearms optics, autonomous vehicle navigation and medical scopes.

Carlos MillerCarlos Miller, Pioneer’s Vice President of Aerospace and Defense, says Optical Black’s low reflectivity offers many advantages over standard black anodize finishes for rigorous applications including satellite telescopes, military guidance systems, firearms optics, autonomous vehicle navigation and medical scopes.

Miller says Optical Black minimizes stray light by absorbing across a broad spectrum – from infrared to ultraviolet light – including laser light. Its exceptional chemical stability also reduces outgassing that can result from colorant breaking down under heat or light, which compromises the accuracy of optical or electronic sensors by clouding them.

“We already supply a number of Fortune 500 companies with Optical Black; customer demands are inspiring new, exciting applications,” Miller says. “We’re deepening our understanding of this finish’s many strengths, to better meet today’s requirements while looking to the future.”

To verify Optical Black performance under the most extreme conditions, Pioneer performed statistical laboratory analysis on three key factors: reflectivity, absorptivity, and lightfastness. Miller said Pioneer is working with a major U.S. university and independent testing organization to obtain third-party data validation.

Optical Black meets Mil-A-8625, Type II Class 2, while also being RoHS-, REACH-, ELV-, and WEEE-Compliant. Optical Black will not fade or discolor over time, and it retains its absorptive characteristics throughout the product’s life.

Headquartered in Green Bay, Wisconsin, Pioneer specializes in providing outsourced metal processing services to customers across a range of industries including industrial, medical, aerospace and defense, automotive, consumer goods, semiconductor equipment and more.