Bill McNabb and David Book both clearly remember the day when a premium threading company was about to put their plating shop to the ultimate test.

After weeks of building a new copper plating line at Electroless Nickel Plating of Louisiana — as well as sinking a ton of hard-earned money into the investment, too — owner McNabb and president Book watched as the customer’s representative took the parts off the line for destructive testing after the qualification test.

“Building the process line depended on passing this test,” McNabb says. “After the test was over, the company rep took his sample parts, and his parting words to us were ‘No one ever passes on the first try.’”

ENPLA did indeed pass on the first try, which didn’t truly surprise their team, nor would it some of their top customers in the oil and gas industry. They also coat in the medical, water purification, automotive, and decorative industries.

High-Phosphorus Electroless Nickel Plating

“We are a true job shop,” McNabb says. “We will plate most parts for most industries, and we have some of the largest nickel tanks in the country. We have plated various parts from all over the U.S. and Canada.”

“We are a true job shop,” McNabb says. “We will plate most parts for most industries, and we have some of the largest nickel tanks in the country. We have plated various parts from all over the U.S. and Canada.”

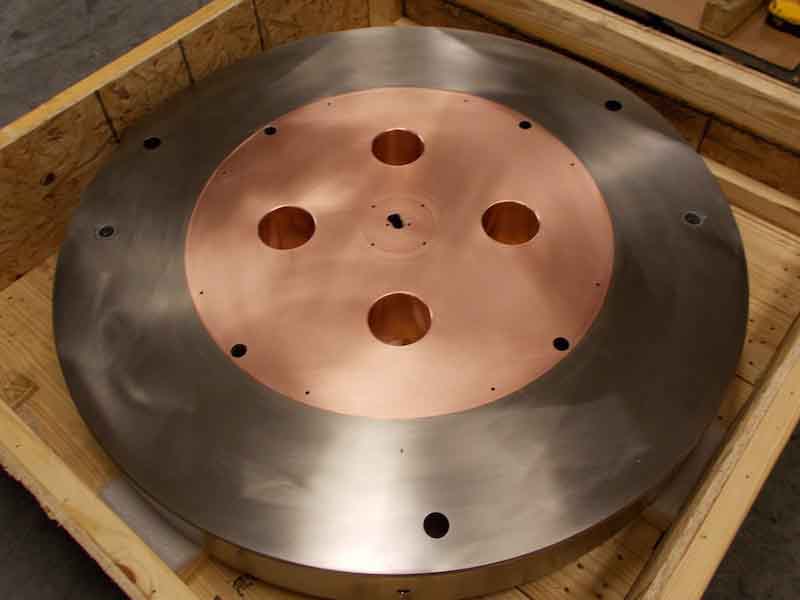

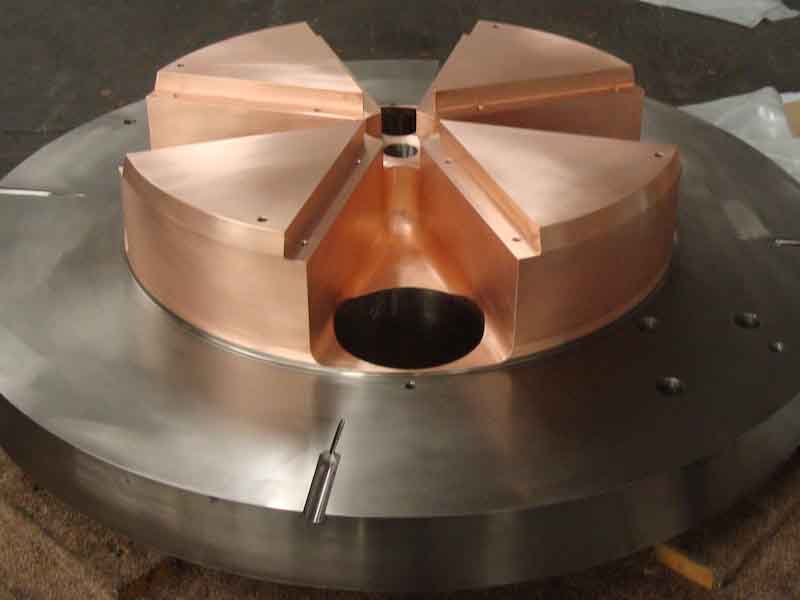

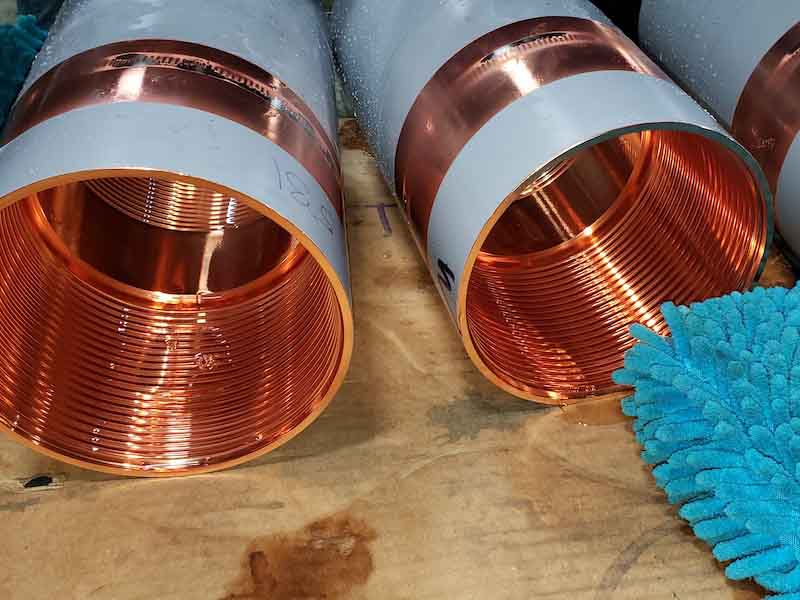

Their primary process has been high-phosphorus electroless nickel plating, but they have also provided acid copper plating for around 20 years. Several years ago, ENPLA installed a dedicated acid copper line just for the premium threading market.

Electroless Nickel Plating of Louisiana was started 46 years ago in Hammond by servicing a single local valve shop, TK Valve. McNabb says nickel plating was relatively new to the valve industry, and as a former employee of TK Valve, he saw an opportunity to offer nickel plating for them.

Book says ENPLA’s tank capacities range from as small as 600 gallons to as large as 4,500 gallons. They have crane capacities up to 20 tons, as well as barrel plating for very small, high-quantity components.

“If the tanks are not enough, we will accommodate as necessary,” Book says.

Low-Mid Phos Nickel Plating for Aluminum

A. J. Calderone, the ENPLA sales manager, says they recently added the acid copper plating line to dedicate it to the premium threading market for down-hole oil wells.

“We also just installed a low-mid phos nickel plating line specifically for aluminum,” Calderone says. “We are still working on adding the specific pretreatment steps to also plate steel, stainless alloys, and copper alloys.”

McNabb says they are actively looking for the next service to provide and have a long-standing agreement with each of our vendors.

“If they can bring us enough new business, we will install their chemistry to plate the work they bring us,” he says. “We are always open to a new process or a new supplier if it comes with an opportunity to grow.”

Since the pandemic outbreak, Operations Manager Charlie Stevens says that ENPLA has had to downsize. They currently have 14 employees across two facilities.

“This goes up and down with the market,” Stevens says. “We typically have about 20 employees across both facilities.”

Customer Service and Quality Systems

Book and Stevens say they attribute the number one source of their success as their customer service and quality systems they have in place. They say they meet and exceed most plating standards and have a culture of quality assurance.

Book and Stevens say they attribute the number one source of their success as their customer service and quality systems they have in place. They say they meet and exceed most plating standards and have a culture of quality assurance.

“Location is also important for the size of parts that we plate,” Book says. “Shipping can quickly become more expensive than the cost of plating. We can provide a very fast turnaround for many of our customers. We perform a lot of same-day and next-day plating.”

Stevens says ENPLA has great relationships with their suppliers, with their biggest partner being Coventya, but they also use chemistry from Atotech, MacDermid Enthone, Metal Chem, and Sifco.

“We provide great service, quality, and we aim to beat due dates,” Calderone says. “As far as attracting new business, we are actively trying to do this now. We are working on upgrading our website and beginning to do a bit more advertising. In the past, most customers found us.”

Tough Year Gets Tougher

A.J. CalderoneThis past year has also been an even harder struggle for Calderone, who previously suffered from Hodgkin’s Lymphoma in 2013 and underwent chemo and radiation as part of his treatment. When he began feeling worse in 2020, a biopsy in August originally determined a tumor was benign.

A.J. CalderoneThis past year has also been an even harder struggle for Calderone, who previously suffered from Hodgkin’s Lymphoma in 2013 and underwent chemo and radiation as part of his treatment. When he began feeling worse in 2020, a biopsy in August originally determined a tumor was benign.

It was only during the surgery that we determined that it was malignant,” Calderone says. “After determining this, the surgeon went ahead and removed my parotid and submandibular salivary glands along with 25 lymph nodes.”

Calderone is recovering now and back to helping get ENPLA also back up to full strength.

Changing Industry Needs

“The industry is certainly changing,” he says. “What got us here is not going to keep us here. Many of our biggest customers over the years no longer exist.”

They have had to look to other industries besides oil and gas, as well as doubling down on oil and gas.

“We are actively looking for other processes and customers,” Calderone says.

McNabb says one of the best things about ENPLA is that they are open to any new challenges.

“We have always had a willingness to invest in something new to support a customer requirement,” he says. “We have also had an open-door policy with our customers. We have worked with customer R&D departments to find the best way to produce quality parts.”

This may involve a different way of processing parts or perhaps a product design change to help ensure the best possible product.

“We are eager to work with our customers to help satisfy their requirements,” McNabb says.

Visit http://www.enla.com