For ChromeTech of Wisconsin, communication is the key to the success of its operation.

It starts internally and manifests itself out to their customers, who have come to appreciate updates and progress reports on parts and projects.

“They say our customer service is key, and our communication is great,” says Zach Henry, vice president. “Our customers tell us often that they like the high quality of our work, pricing, and quick turnaround. We can do high-volume work and hold time schedules. But we also develop relationships and partnerships with our customers.”

Specializing in Hard Chrome, Sulfamate Nickel, and EN

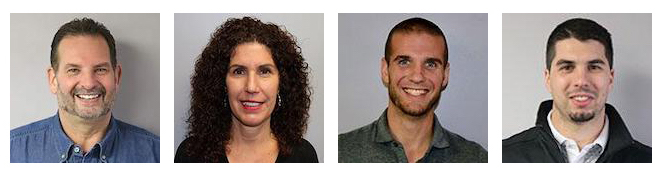

President Alan Henry, Administrative Manager Vickie Henry; Vice President Zach Henry, and Production Manager Ross Henry.ChromeTech is an ISO-certified industrial plating operation in Franklin, WI, that was founded in 1984. They provide functional plating services to a wide variety of industries, specializing in the areas of hard chrome, sulfamate nickel, electroless nickel, and nickel-chrome plating.

President Alan Henry, Administrative Manager Vickie Henry; Vice President Zach Henry, and Production Manager Ross Henry.ChromeTech is an ISO-certified industrial plating operation in Franklin, WI, that was founded in 1984. They provide functional plating services to a wide variety of industries, specializing in the areas of hard chrome, sulfamate nickel, electroless nickel, and nickel-chrome plating.

Many of their customers are in agricultural, appliance, automotive, construction, defense, oil and gas, paper, power generation, and railroad industries.

Five years ago, they put on a 22,000 square foot addition to their building to take them up to 44,000 square feet. And they continue to expand as new customers come online.

“We are currently building a new electroless nickel line,” says owner Alan Henry. “We are also adding a new polisher with an auto load and unload station, and a bigger walk-through oven – our third oven – has been purchased to increase our efficiency.”

Becoming ‘One-Stop Shop’ for Customers

ChromeTech has 28 employees and is running three shifts. Production Manager says Ross Henry says the key to growth for the company moving forward is expanding into different areas to be a “one-stop-shop for our customers.”

ChromeTech has 28 employees and is running three shifts. Production Manager says Ross Henry says the key to growth for the company moving forward is expanding into different areas to be a “one-stop-shop for our customers.”

“Continued growth is important, and so is continuous improvement,” he says. “Becoming more efficient is very important, especially with seven EN lines.”

Owner Alan Henry is a-second generation plating expert who began his career with his father in the 1970s. He moved on to a different plating shop and was asked to run the shop while the owner was in the hospital. Unfortunately, the health reasons never allowed the owner to come back.

“I loved the plating business and was confident I could provide great service within the industry,” Alan says. “I tried to buy the company that I had worked for, but they would not sell.”

37 Years Later and Still Growing

In 1984, he left and opened ChromeTech, which soon proved to be inadequate for the flourishing business. In 1989, a much larger facility was built specifically for the hard chrome and sulfamate nickel plating operations, with new waste treatment, ventilation, and processing systems.

“I’m so glad I started my own company because two years later that other company went out of business,” Alan says. “37 years later, and ChromeTech is still growing.”

An automated, programmable hoist line was added in 1994 to accommodate high-volume requirements. Since then, ChromeTech has added additional mechanical finishing equipment and an electroless-nickel plating line, and Alan has been joined by the third generation, his sons Zach and Ross.

Alan’s wife, Vickie Henry, runs the administrative side of the business. Other team leaders are Andrea Dillon, Quality Manager; Scott Boie, Maintenance Manager; and Scott Lindberg, Business Development Specialist.

Training Through NASF and ASQ

ChromeTech has a dedicated, trained, and educated workforce. They provide in-house classes and training to the team members, as well as professional training and certification through their affiliation with the National Association of Surface Finishing (NASF) and the American Society of Quality (ASQ).

ChromeTech has a dedicated, trained, and educated workforce. They provide in-house classes and training to the team members, as well as professional training and certification through their affiliation with the National Association of Surface Finishing (NASF) and the American Society of Quality (ASQ).

“We work hard at improving the capabilities of our people and processes,” Vickie Henry says. “Part of our ongoing training is through weekly Tool Box training meetings where we cover everything from procedures and equipment to safety.”

Zach Henry says they create detailed work instructions for each machine and workstation. They also created a detailed work ticket for each part that contains clear, written instructions for each step of the process, as well as pictures.

“Our employees have the capabilities to communicate with a phone app that allows them to send messages and pictures to the group for questions,” he says. “As we all work together, everyone benefits.”

Capable Of High-Volume Production In Excess Of 500,000 Pieces

With their automated and manual systems, ChromeTech can process large, one-of-a-kind parts up to 8,000 pounds and is capable of high-volume production in excess of 500,000 pieces weekly.

With their automated and manual systems, ChromeTech can process large, one-of-a-kind parts up to 8,000 pounds and is capable of high-volume production in excess of 500,000 pieces weekly.

The facility’s top suppliers are Plating International, Scientific Control Labs, Speedy Metals, ScrubAir Systems, Jet Rack, and Grant Fabrication and Welding.

Lindberg says ChromeTech only does a little bit of marketing to bring in new customers. They keep their website up-to-date and use some social media.

“Lately, it seems that business is finding us,” he says. “Word of mouth is still the best advertising.”

Alan Henry said one of his proudest moments in the finishing industry was when his sons — Zach and Ross — joined the company to help him grow it. He says the entire ChromeTech workforce is experienced and dedicated to the workmanship they deliver.

“We have over 200 years of combined knowledge here,” Alan says. “We can solve problems that others may not be able to solve. We retain business by giving customers what they want – quality, communication, and quick turnaround. We can move a lot of work out and are able to adapt to customer needs daily.”

Visit https://chrometech.net