Scott Kettler enjoys the strategy of taking Pioneer Metal Finishing from being a what business – “What finish do you need?” — to a why business.

Scott Kettler“Why are you looking for a surface engineered finish?” says Kettler, president and COO of Pioneer Metal Finishing, one of the largest metal finishing companies in North America from a general processor standpoint, operating 11 locations in the U.S. and one in Mexico.

Scott Kettler“Why are you looking for a surface engineered finish?” says Kettler, president and COO of Pioneer Metal Finishing, one of the largest metal finishing companies in North America from a general processor standpoint, operating 11 locations in the U.S. and one in Mexico.

Kettler loves transformation and is overseeing it at Pioneer, where he started as COO in early 2018 after working in the high-tech fields of electronics manufacturing and digital printing. The president title was added in 2021.

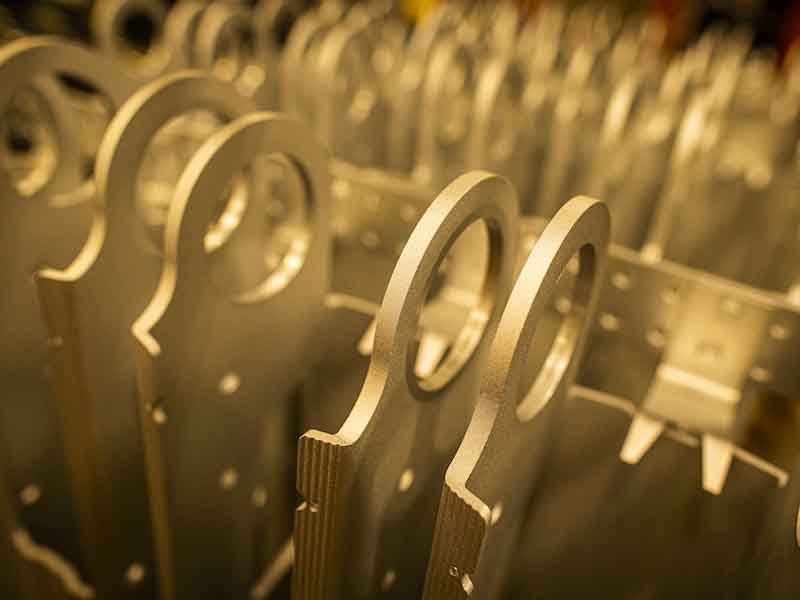

The Green Bay, Wisconsin-based Pioneer has more than 1,000 team members working in over 800,000 square feet of manufacturing space in their various locations. Kettler says their focus is serving four primary markets: automotive, industrial equipment, medical, and aerospace/defense.

“Across those markets, the metals are similar, but our services are unique,” Kettler says. “We have the expertise and capabilities to provide thought leadership in surface engineering and outstanding value to our customers, instead of simply being an order-taker competing on price.”

Extensive Geographical Reach

The company’s growing geographical reach enables Pioneer to make a big impact. Last year, they served customers in all 50 states and 11 countries, including Australia. In all total, the company finishes over 560 million parts annually.

The company’s growing geographical reach enables Pioneer to make a big impact. Last year, they served customers in all 50 states and 11 countries, including Australia. In all total, the company finishes over 560 million parts annually.

Pioneer marked its 75th anniversary in 2020, and the company celebrated by continuing its growth trajectory with three strategic acquisitions:

- Pilkington Metal Finishing in Salt Lake City, Utah

- Indianhead Plating in Chippewa Falls, Wisconsin.

- Electrochem Solutions in Union City, California

The acquisitions were added to existing facilities in Green Bay; two locations in Warren and one in Monroe in Michigan; Portland, Oregon; South Bend, Indiana; Minneapolis, Minnesota; and in Queretaro, Mexico.

Kettler says all three companies acquired in 2020 were healthy with strong potential.

“Acquisitions bring us a lot of talent and experience,” he says, adding that Pioneer’s commercial team, proprietary technology, and quality management system help the new organizations improve their customer-facing performance metrics while also expanding their capabilities.

Customers of the acquired firms benefit from the ability to tap into Pioneer’s enterprise-wide solution, Kettler says, including enhanced engineering services and reduced supply chain risk.

Factors That Drive Expansion

Kettler praises the role of Aterian Investment Partners, the private equity firm that purchased Pioneer in 2018.

Kettler praises the role of Aterian Investment Partners, the private equity firm that purchased Pioneer in 2018.

“They love our business and are strong, supportive partners willing to invest and support our evolution,” he says. “Aterian’s leadership helps ensure we’re making sound investments to keep expanding.”

Kettler says three factors drive Pioneer’s acquisition strategy:

- Filling a geographic gap in facility coverage.

- Increasing presence in certain markets, such as medical or aerospace/defense.

- Buying new technical capabilities.

Electrochem Solutions, for example, checked all three boxes for Pioneer.

“It had a desirable Silicon Valley location serving semiconductor manufacturing with surface finishes for deposition chamber equipment,” Kettler says.

After acquiring Pilkington’s extensive Nadcap experience, Pioneer says it used that skill set to support other facilities’ certification efforts; Minneapolis is complete, and Portland is in process.

Kettler sees Pioneer’s growth continuing both organically and through further acquisitions, with the fragmented metal finishing industry offering many potential targets, especially serving medical and aerospace/defense customers.

“We see an opportunity to continue stitching together a broader solution across North America with other facilities,” he says.

Offering Enterprise Solution

Kettler says size and scalability are what differentiates Pioneer from others in the finishing industry. They can offer an unmatched enterprise-level solution, he says, with a regional strategy that’s evolved to span an increasing number of locations across North America.

Kettler says size and scalability are what differentiates Pioneer from others in the finishing industry. They can offer an unmatched enterprise-level solution, he says, with a regional strategy that’s evolved to span an increasing number of locations across North America.

“We’re focused on thought leadership in four core areas: functional aesthetics, functional surfaces, surface enhancements, and tribological management,” Kettler says. “To meet and anticipate customer needs, we’re continually developing new, scalable solutions leveraging the latest technology.”

Pioneer’s value proposition is “mission-critical surface engineering,” Kettler says, and the company prides itself on supporting programs and projects where failure is truly not an option.

“We’re not the lowest-cost provider,” he says. “But our track record of performance and delivering on our promises are key reasons our customers come back to us.”

Its large scale and comprehensive capabilities enable Pioneer to have conversations with larger customers that can utilize their full breadth of services and capabilities. Kettler says OEMs particularly are looking to consolidate their supply chains rather than working with multiple finishers.

“We can offer redundant facilities with common IT, ERP, and QMS platforms seamlessly help customers with risk mitigation and supply chain continuity if a crisis occurs, either natural or man-made,” he says.

Pioneer’s centralized engineering services engage early with customers in optimizing finish applications, problem-solving, new product development, and onboarding.

According to Kettler, becoming a strategic partner also takes a deeper understanding of their customers’ problems.

“We must look through a customer’s eyes at their challenges and how we can best solve them,” he says.

Thanking the Team

Kettler credits Pioneer’s people for the company’s success.

Kettler credits Pioneer’s people for the company’s success.

“They truly care about their jobs, their peers, and their customers,” he says, adding they are always challenging themselves to improve in areas like quality, delivery, and responsiveness.

Kettler was proud of Pioneer’s COVID response as an essential business. When two facilities were shut down temporarily due to the automotive downturn, employees at other locations rallied by raising productivity levels and working extra hours to help.

When some customers pivoted production during COVID, Pioneer adapted quickly, for example, processing ventilator components at several locations. Team members showed resolve to keep working amid other potential disruptions like wildfires, earthquakes, and civic protests.

Pioneer’s growth plans include finding and retaining the right talent in a tight labor market, and Kettler believes telling Pioneer’s story is vital.

“When we talk about our history, legacy, and future strategy, it’s easier to keep employees interested and enthusiastic,” he says, noting that a number of employees have 25-30 years of tenure and teaming those veterans with younger personnel strikes a nice balance.

“We’re all excited to help continue building on Pioneer’s legacy, now 76 years strong,” Kettler says. “It’s a continual challenge to get better as an organization, which is why I get out of bed every morning.”

Visit https://www.pioneermetal.com

All photos provided by Pioneer Metal Finishing. Copyright Pioneer Metal Finishing. Not to be used without permission of Pioneer Metal Finishing.