Aside from its sterling clean electroplating operation and its depth of knowledge in some of the most difficult finishing processes, Sheffield Platers in San Diego is a contradiction in many ways.

The third-generation company traces its roots back to 1946 when the current owner’s grandfather specialized in repair and replating in the hospitality industry. He named it after the notorious Sheffield, England, plating process of silver and copper that was world renown for some of the best sterling silver items made in the Old World.

Brothers Mark and Dale Watkins and their team have made Sheffield Platers one of the top plating operations in the U.S.Today, they have left behind the spoons, forks, and fine silverware to finish hi-tech parts for various industries, including military and commercial electronics, hermetic connectors, semiconductor, as well as many areas of commercial, military and aerospace manufacturing.

Brothers Mark and Dale Watkins and their team have made Sheffield Platers one of the top plating operations in the U.S.Today, they have left behind the spoons, forks, and fine silverware to finish hi-tech parts for various industries, including military and commercial electronics, hermetic connectors, semiconductor, as well as many areas of commercial, military and aerospace manufacturing.

“We have a technical staff that is second to none,” says Dale Watkins, company president. “In this industry, if your customers can see that you understand every aspect of your processes and how it affects their products, they will continue to seek out your expertise.”

SPI Connectors, Cadmium, PTFE, and Hermetic Functional Coatings

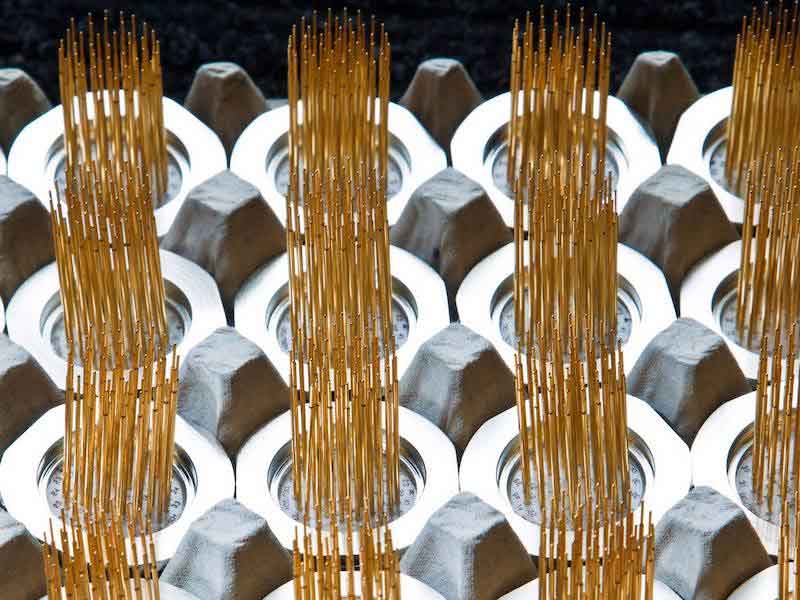

The other contradiction is that — with the extensive expertise in electroless nickel, gold, black nickel for Serial Peripheral Interface (SPI) connectors, cadmium, PTFE, and hermetic functional coatings — Sheffield Platers operates out of an 21,000-square-feet facility that maintains ISO 9001:2008 certification and Nadcap accreditation to serve the aerospace market.

It’s not one of the larger finishing operations in the extremely competitive Southern California market, but it is an extremely efficient shop with 62 employees who all have a fastidious adherence to quality, cleanliness and environmental responsibility that continues to draw in customers.

“We are now at a stage where word of mouth in some of our niche’ processing capabilities can lead customers to inquire about our abilities,” says Mark Watkins, Sheffield’s Vice President and Dale’s brother. “Once we have a technical discussion with them, they usually send the business to us.”

Original Focus was Hospitality Industry

Sheffield Platers has extensive expertise in electroless nickel, gold, black nickel for SPI connectors, cadmium, PTFE, and hermetic functional coatings Sheffield Platers was founded in 1946 by Roy Watkins, whose business focus was the hospitality industry. Dale and Mark’s father, Dale Sr., soon joined Roy to help Sheffield become one of the preeminent silversmiths in California. Dale Sr. became the sole proprietor of Sheffield in 1976.

Sheffield Platers has extensive expertise in electroless nickel, gold, black nickel for SPI connectors, cadmium, PTFE, and hermetic functional coatings Sheffield Platers was founded in 1946 by Roy Watkins, whose business focus was the hospitality industry. Dale and Mark’s father, Dale Sr., soon joined Roy to help Sheffield become one of the preeminent silversmiths in California. Dale Sr. became the sole proprietor of Sheffield in 1976.

When their father passed suddenly in 1991, Dale and Mark left their full-time jobs outside of the finishing industry to become the owners of Sheffield Platers. Three years later, the brothers purchased a new facility in Sorrento Mesa north of San Diego.

However, they quickly saw a change in the direction of the electroplating industry from an environmental standpoint. That made the Watkins brothers’ first goal to ensure long-term sustainability of the company by installing a closed loop environmental system.

All of the waste materials generated by the facility is hauled away and never make its way into the Publicly Owned Treatment Works. This approach to treating waste in a responsible manner led to the awarding of the Model Shop Award by the California Department of Toxic Substances Control, an award which has only been presented to three electroplating shops in the state.

DTSC Metal Finishing Model Shop Program

The DTSC’s Metal Finishing Model Shop Program is a unique voluntary pollution prevention program designed to help a metal finishing business run a cleaner and safer shop. The program assists metal finishing businesses in identifying possible sources of pollution in their plants, and to develop ways to reduce the hazardous waste. The goals are to help finishers:

The DTSC’s Metal Finishing Model Shop Program is a unique voluntary pollution prevention program designed to help a metal finishing business run a cleaner and safer shop. The program assists metal finishing businesses in identifying possible sources of pollution in their plants, and to develop ways to reduce the hazardous waste. The goals are to help finishers:

- Eliminate or reduce waste generation

- Conserve energy and water

- Reduce operating costs

- Increase compliance with environmental regulations

- Improve employee health and safety

- Be environmentally responsible

- Receive recognition for their pollution prevention efforts

The award is expensive to maintain, Dale says, but well worth it.

“As president and environmental officer, I spend 30% of my valuable time managing environmental and safety issues,” Dale says. “Why? Because the nature of metal finishing businesses require a substantial commitment from the ownership to comply with the myriad of overlapping regulations.”

Vincent Noonan, Sheffield Platers’ Vice President Strategic Operations, says the company’s facilities are so much in compliance that the San Diego Fire Department uses the shop as an example to show other plating companies how to properly operate their own facilities.

“Our model shop award was given after the first initial interview,” Noonan says.

Proprietary SPI Connector Black Process

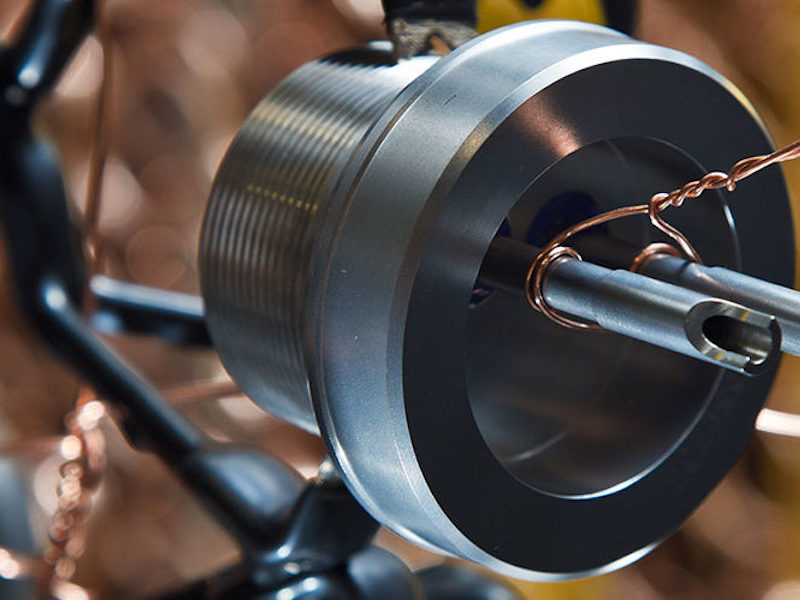

On top of its cleanliness and compliance capabilities, Sheffield Platers has also become experts in the SPI connector field, a crucial element in the military and aerospace industry. Sheffield received a patent for its SPI Connector Black proprietary duplex layered plating and blackening process for electronic connectors, enclosures or other substrates that need to meet the stringent requirements of MIL-DTL-38999 or commercial specifications requiring cadmium alternative coatings.

On top of its cleanliness and compliance capabilities, Sheffield Platers has also become experts in the SPI connector field, a crucial element in the military and aerospace industry. Sheffield received a patent for its SPI Connector Black proprietary duplex layered plating and blackening process for electronic connectors, enclosures or other substrates that need to meet the stringent requirements of MIL-DTL-38999 or commercial specifications requiring cadmium alternative coatings.

Noonan says SPI Connector Black is compliant with WEEE, RoHS, ELV and other specifications that require cadmium and lead-free deposits, and it passes 500-750 hours neutral salt spray testing on fully assembled connectors

“It produces a matte black finish comparable to the reflectivity of olive drab chromate,” he says. “It’s a conductive coating that shows low contact resistance before and after corrosion testing, and is easily distinguishable from PTFE, aluminum electroplate, and cadmium/olive drab coatings, which is necessary to ensure that incompatible connections are not made in the shipyard, aircraft or vehicle assembly shops.”

When they aren’t creating their own proprietary chemicals, Sheffield Platers partners with Coventya, Metalchem, and Technic as suppliers of chemistry for their main processes. Miles chemical takes care of their waste treatment and ancillary consumable chemicals.

Taking On Tough Plating Issue

Dale Watkins and Vincent Noonan are actively involved in the NASF chapter in Southern California, and on the national level.Under the leadership of Jennifer McCown, the Director of Quality for Sheffield Platers, Dale Watkins says their team enjoys taking on tough issue that needs solving for a current or potential partner.

Dale Watkins and Vincent Noonan are actively involved in the NASF chapter in Southern California, and on the national level.Under the leadership of Jennifer McCown, the Director of Quality for Sheffield Platers, Dale Watkins says their team enjoys taking on tough issue that needs solving for a current or potential partner.

“We have a blast,” Dale says. “Our technical team really enjoys the fix. If we can provide a solution that quickens a lead-time or provides a solution to a long-term issue, we consider that a great day.”

Noonan says both Mark and Dale Watkins have given Sheffield Platers all the tools it needs for their established technical and operations team.

“Thanks to ownership willingness to re-invest in the company, we have the agility to pivot and develop new revenue streams,” Noonan says. “This was particularly valuable when Covid hit. When one stream of revenue slows, it is imperative to know that the diversification of processes will allow continued growth. This has always been a part of our strategic planning.”