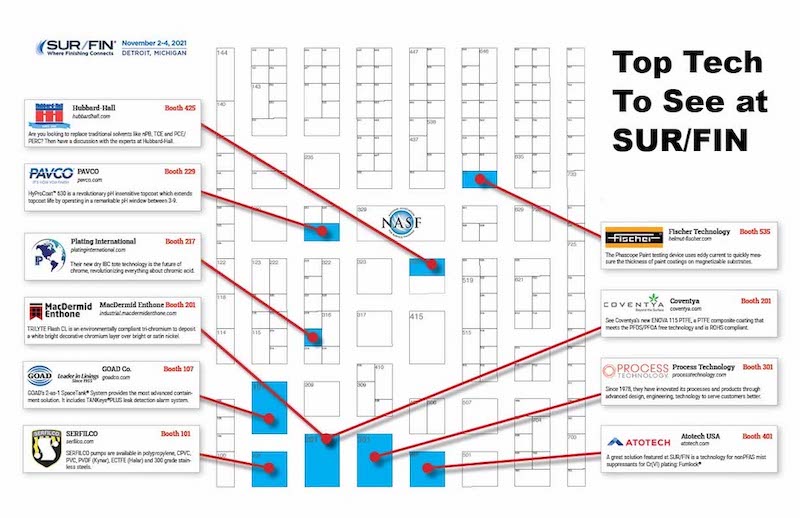

There will be more than 130 exhibitors at the NASF's SUR/FIN conference representing some of the most advanced technology in the finishing and coating industry.

Attendees will have a field day seeing the latest advancements in chemicals, equipment, and services at the show, but there are also a few booths that are "Must See" for those who attend the show Novermber 2-4 in Detroit, Michigan.

We've assembled a short list of the latest technology and services that would be well worth your time to stop by and make a visit with a representative.

You'll find the latest solvent replacements, new advanced topcoats, equipment for working with chromic acid, new technology in tanks and pumps, as well as the latest chemistries that finishers will definitely want to see if their facility can utilize.

Hubbard-Hall: A Choice for Every Cleaning Challenge

Are you looking to replace traditional solvents like nPB, TCE and PCE/PERC?

Are you looking to replace traditional solvents like nPB, TCE and PCE/PERC?

Then head to Booth 245 to have a discussion with the experts at Hubbard-Hall, which has been tackling solvent issues head-on for nearly 170 years and offers both aqueous and solvent chemistries.

Whether you want a lower-impact solvent or to get out of solvents altogether, Hubbard-Hall has the right cleaner for your operation.

Hubbard-Hall is the only company committed to helping you reduce the cost, complexity and chemical consumption of surface cleaning. Among its products you will more about include:

- Aquaease® 2289 which reduces cleaning steps to save time and money.

- Aquaease Infinity® that reclaims 95% of your cleaner.

- Next-Gen solvent DUALENE™, which is the first pre-stabilized modified alcohol developed for metal cleaning.

In addition, Hubbard-Hall can help you lower the “Real Cost of Cleaning.” The price of equipment and chemicals is just one consideration when looking at the cost of your cleaning operations. The higher cost comes from defects due to poor cleaning that cause rework, rejects, and labor. In fact, job and captive shops attribute 17% of their quality defects to poor pretreating and cleaning.

Conversely, Hubbard-Hall has learned that shops that adhere to a strict cleaning process are more than 4x as likely to have a 1% or lower quality defect rate and say they have 40% fewer defects due to poor cleaning versus those with a loose process or occasional cleaning. Booth 425. Visit www.hubbardhall.com

Atotech: Market Leader in Advanced Plating Solutions

Atotech is a leading specialty chemical technology company and a market leader in advanced electroplating solutions. Atotech delivers chemistry, equipment, services and software for innovative technology applications through an integrated systems-and-solutions approach. Atotech solutions are used in a wide variety of end-markets, including smartphones and other consumer electronics, communications infrastructure, and computing, as well as in numerous industrial and consumer applications such as automotive, heavy machinery and household appliances.

Atotech is a leading specialty chemical technology company and a market leader in advanced electroplating solutions. Atotech delivers chemistry, equipment, services and software for innovative technology applications through an integrated systems-and-solutions approach. Atotech solutions are used in a wide variety of end-markets, including smartphones and other consumer electronics, communications infrastructure, and computing, as well as in numerous industrial and consumer applications such as automotive, heavy machinery and household appliances.

Atotech, headquartered in Berlin, Germany, is a team of 4,000 experts in over 40 countries and has manufacturing operations across Europe, the Americas, and Asia. With its well-established innovative strength and industry-leading global TechCenter network, Atotech delivers pioneering solutions combined with unparalleled on-site support for over 8,000 customers worldwide.

One such solution which will be featured at SUR/FIN is a technology for nonPFAS mist suppressants for Cr(VI) plating; Fumlock®. PFAS is an emerging issue in the electroplating industry and Atotech has a clear strategy of investing so we can be proactive in helping you navigate through these dynamic changes. We strive to meet the global demand for more sustainable technologies and chemicals and, to that end, we have developed Fumalock®, which is currently the most advanced and production-proven nonPFAS mist suppressant for Chromium plating on the global market. For sustainable technologies, Atotech can help you find a solution perfectly suited to your needs. Booth 401. Visit www.Atotech.com

GOAD: Introduces New 2-as-1 SpaceTank System

GOAD’s 2-as-1 SpaceTank® System provides the most advanced containment solution in the world. This system offers secondary containment at the tank itself and allows for easy, full tank leak monitoring of the inner tank so there are no undetected, silent or surprise leaks, ever.

GOAD’s 2-as-1 SpaceTank® System provides the most advanced containment solution in the world. This system offers secondary containment at the tank itself and allows for easy, full tank leak monitoring of the inner tank so there are no undetected, silent or surprise leaks, ever.

SpaceTank System will include GOAD’s TANKeye PLUS leak detection alarm system. The TANKeye PLUS system provides continuous pre-leak detection; alerting operators (visual and audible alarm) if a pre-leak occurs. Attain 100% assurance of your tank's integrity without the need for periodic maintenance checks. If a pre-leak is detected, the alert allows for the non-emergency scheduling of repair since the detection occurs before there is an active leak to the tank exterior. GOAD provides peace of mind. Booth 107. Visit www.Goadco.com

Pavco: New Plating and Post Plate Alternatives

Pavco is excited to showcase the largest release of new products in our history; with offerings both in plating and post plate alternatives.

Pavco is excited to showcase the largest release of new products in our history; with offerings both in plating and post plate alternatives.

Highlights will include HyProCoat™ 630, our revolutionary pH insensitive topcoat which greatly extends topcoat life by operating in a remarkable pH window of between 3-9. Plating operations will benefit from less dependance on thorough rinsing after trivalent passivation.

Pavco’s next generation high performance passivate is the cobalt free HyProTec™ LD, which significantly outperforms existing HyProTec™ while relieving users of the regulatory or pricing pressures common in cobalt. In addition to this, the synergistic performance increase it achieves with the use of a topcoat is remarkable.

Lastly is BlazeZinc™, the industry’s newest and most advanced alkaline zinc system offering amazing versatility with improved low current density attributes and exceptional baking characteristics. Say goodbye to zinc deposit appearance changes after hydrogen embrittlement relief or other high temperature bake operations. Booth 229. Visit www.Pavco.com

Process Technology: Continually Innovating Products

Since 1978, Process Technology has continually innovated our processes and products through advanced design, engineering, technology, digitization, production, and training to serve our customers better.

Since 1978, Process Technology has continually innovated our processes and products through advanced design, engineering, technology, digitization, production, and training to serve our customers better.

Process Technology serves the Surface Finishing, Semiconductor, Electroplating, Flat Panel Display (FPD), Photovoltaic (PV, Solar Cell), Printed Circuit Board, Aerospace, Automotive, Aquaculture, and Medical Device Industries. Products include LUFRANTM - DI Water and Chemical Heaters, Chemical and Solvent Heaters, Quartz Heaters, Fluoropolymer (PTFE) Heaters, Electric Immersion Heaters, Heat Exchangers, High-Temperature Filter Chambers, Power Supplies (DC, Pulse, Reverse), Controls, and Accessories. ISO 9001:2015 with Design Certified. Booth 301. Let’s innovate together – contact us at www.ProcessTechnology.com

Plating International: One Plate for Easier EN Process

For 50 years, platers have used three different components for electroless nickel baths. A, B and C. Many still use these three components today. It’s inefficient, inconvenient, and costly, but it’s just the way it’s always been done. What if there was a better way? One Plate single component electroless nickel from Plating International replaces the three-solution system you use now with just one single solution that does everything your current system does, only better!

For 50 years, platers have used three different components for electroless nickel baths. A, B and C. Many still use these three components today. It’s inefficient, inconvenient, and costly, but it’s just the way it’s always been done. What if there was a better way? One Plate single component electroless nickel from Plating International replaces the three-solution system you use now with just one single solution that does everything your current system does, only better!

You can order, stock, make-up and replenish all from a single drum, not three. With One-Plate, there’s no chance of mixing up B and C components, because there’s only one with One-Plate. With One-Plate, there’s no chance for the bath to get out of balance, because all the ingredients are in the single One-Plate solution. . A single solution makes your plating process easier and faster. Save on inventory, labor time, and energy. Experience consistently higher quality and longer bath life with One-Plate. Available in low, mid and high phos, as well as composites with Teflon, diamond, silicon carbide, and boron nitride. Booth 217. Visit www.PlatingInternational.com

SERFILCO: Still Pumping with Passion after 60 years

“I have a difficult Chemical application” is music to SERFILCO's ears: the more corrosive, the more complex, the more challenging the better, because that is what we do, that is where we thrive.

“I have a difficult Chemical application” is music to SERFILCO's ears: the more corrosive, the more complex, the more challenging the better, because that is what we do, that is where we thrive.

SERFILCO is a second-generation family owned business, headquartered outside of Chicago in Northbrook Illinois. After posting sales in 2020 to 60 plus countries we live up to our Mantra of "Global Products, Local Service And Advice You Can Rely On.

To be successful in business, when you strip away the distractions and commotion, you need three basic components: Market, Knowledge and Passion. A very simplistic view, but one that in many ways defines us at SERFILCO. The staff at SERFILCO are liquid handing experts and proud of it. Globally, we celebrate over 900 years of collective service within the ranks and bring a formidable knowledge base to draw from to overcome the most difficult and diverse applications. Add to that a huge dose of innovation, talent, and investment in state-of-the-art facilities and you get a global supplier to Chemical processers that has continued to grow through the 6 decades of business as we have at SERFILCO.

SERFILCO’ S commitment to molding better plastic products to facilitate safe and clean transfer, filtration and agitation of corrosive chemicals fits entirely with our dedication to environmental responsibility and waste minimization. Every filter has a pump, and when it comes to pumps, SERFILCO has never been complacent. Our talented R&D team is constantly looking at new products alongside improvements to existing flagship’s that have been in the fleet for years. WAs liquid handling experts, materials of construction are crucial to getting it right every time. SERFILCO pumps are available in polypropylene (PP), CPVC, PVC, PVDF (Kynar), ECTFE (Halar) and 300 grade stainless steels, built in vertical seal-less, horizontal direct drive sealed, and horizontal magnetic drive. With flow capacities of 2 to 1,200 gallons per minute using 1/40th HP up to 40 HP motors, SERFILCO pumps will not let you down. Booth 101. Visit www.serfilco.com

MacDermid Enthone: TRILYTE Flash CL on Nickel

MacDermid Enthone Industrial Solution’s TRILYTE Flash CL is an environmentally compliant trivalent chromium plating process used to deposit a white bright decorative chromium layer over bright or satin nickel deposits.

MacDermid Enthone Industrial Solution’s TRILYTE Flash CL is an environmentally compliant trivalent chromium plating process used to deposit a white bright decorative chromium layer over bright or satin nickel deposits.

For automotive applications, the process is highly tolerant to attack from calcium chloride containing salts. When used in combination with MacDermid Enthone satin or bright nickel processes and the DUR NI microporous noble nickel, TRILYTE Flash CL provides excellent CASS performance. The TRILYTE Flash CL deposit color is consistent over all current density ranges. The process is tolerant to current interruptions, provides excellent uniform metal distribution and reduces or eliminates burning when compared to conventional hexavalent chromium deposits.

For post-treatment, TRILYTE CP 3000 is designed especially for use with TRILYTE processes. It is an environmentally-compliant chromium-free post dip for electroplated trivalent chromium deposits. It significantly improves the corrosion resistance of the decorative coating system. Performance in standard corrosion tests such as NSS and CASS is improved by applying TRILYTE CP 3000 on top of the electroplated chromium layers without affecting part appearance. Booth 201. Visit https://industrial.macdermidenthone.com

COVENTYA: ENOVA 115 PTFE High Phos EN Composite

In the continuing efforts to promote eco-friendly products Coventya's has introduced ENOVA 115 PTFE, a PTFE composite coating that meets the PFOS/PFOA free technology and is ROHS compliant. The ENOVA 115 PTFE process is an electroless nickel-phosphorus plating system that incorporates polytetrafluoroethylene (PTFE) as occluded particles in a high phosphorus electroless nickel deposit matrix with a capability range from 15 to 25% by volume PTFE inclusion. This unique process is specially designed to produce a consistent amount of uniformly dispersed PTFE throughout the EN deposit.

In the continuing efforts to promote eco-friendly products Coventya's has introduced ENOVA 115 PTFE, a PTFE composite coating that meets the PFOS/PFOA free technology and is ROHS compliant. The ENOVA 115 PTFE process is an electroless nickel-phosphorus plating system that incorporates polytetrafluoroethylene (PTFE) as occluded particles in a high phosphorus electroless nickel deposit matrix with a capability range from 15 to 25% by volume PTFE inclusion. This unique process is specially designed to produce a consistent amount of uniformly dispersed PTFE throughout the EN deposit.

ENVOA 115 PTFE deposits are excellent for providing very low friction values, especially in applications where sliding wear is present and the wear mechanism is induced by light, well-distributed loads. The release and anti-stick properties of ENVOA 115 PTFE deposits are excellent, resulting in increased life for tools, molds, dies, and other coated surfaces. The ENOVA 115 process offers the following benefits:

- RoHS compliant deposit

- Meets PFOS/PFOA free regulation

- Wide range of PTFE deposit percent volume for all application demands

- Uniform distribution of PTFE particles

- Excellent bath stability

- Low operating cost

- Plated surfaces have excellent wear resistance and high lubricity

Fields of application:

- Applications where High corrosion resistance is required

- Chemical/ Oil and Gas Industry

- Automotive Industry

- Aerospace Industry

- Military Industry

- Electronics

Booth 201. Please contact Coventya at 216-351-1500, or visit www.coventya.com

Fischer Technology: Measuring Coating Thickness

Fischer Technology’s pen-like Phascope Paint testing device uses the eddy current method to quickly measure the thickness of paint coatings on magnetizable substrates such as steel or iron, as well as non-magnetic metals such as aluminum, without the need to switch devices or probes. It then uses an smartphone or tablet app for data analysis.

Fischer Technology’s pen-like Phascope Paint testing device uses the eddy current method to quickly measure the thickness of paint coatings on magnetizable substrates such as steel or iron, as well as non-magnetic metals such as aluminum, without the need to switch devices or probes. It then uses an smartphone or tablet app for data analysis.

A conductivity compensation feature ensures accurate measurement results, even when testing samples of different aluminum alloys with different conductivities, the company says.

This makes the device well-suited for a variety of applications, from automotive to others requiring heavy corrosion protection. It can handle a measuring range to 98 mils and is well-suited for very thick coatings, Fischer says. Booth 535. Visit www.fischer-technology.com