Joe Dudenhoeffer walks at a brisk pace through his shop at Klein Plating Works early one Friday morning and sees the good and the struggles of the finishing business.

“Business is good, but this is also extremely frustrating,” says Dudenhoeffer, a fourth-generation owner of the company in Erie, Pennsylvania.

“The work and the opportunities are there, but we can’t grow because it is difficult to hire new employees,” he says. “I have a great workforce here, and they are all like family to me. But how long can you ask your employees to work long hours and weekends before things implode? Employee burnout is just another piece of the puzzle that business owners need to worry about.”

Workforce development is a problem facing not just all finishing and coating operations but any manufacturing business in the U.S., as well as retail and other industries.

Transition to More Automation

The Klein Plating Works team stand behind President Joe Dudenhoeffer.For Dudenhoeffer and KPW, it is also a time of transition at the 107-year-old business started by his ancestors — Frank and Oscar Klein — back in 1915. Dudenhoeffer has begun a multi-million-dollar upgrade program to automate many of the processes at the 32,000 square foot facility.

The Klein Plating Works team stand behind President Joe Dudenhoeffer.For Dudenhoeffer and KPW, it is also a time of transition at the 107-year-old business started by his ancestors — Frank and Oscar Klein — back in 1915. Dudenhoeffer has begun a multi-million-dollar upgrade program to automate many of the processes at the 32,000 square foot facility.

“We started major renovations about three years ago to invest in newer lines, updated technology to run those lines, and new shop control software,” he says. “Due to supply-chain issues, it really has been like pulling teeth, but our goal is to be a more highly-efficient shop with tighter controls. As a large job shop, we plate millions of different parts of varying substrates, each requiring different underplates and final finishes. This complexity demands us to find a way to be as automated as possible while still being able to be flexible for our customers’ needs.”

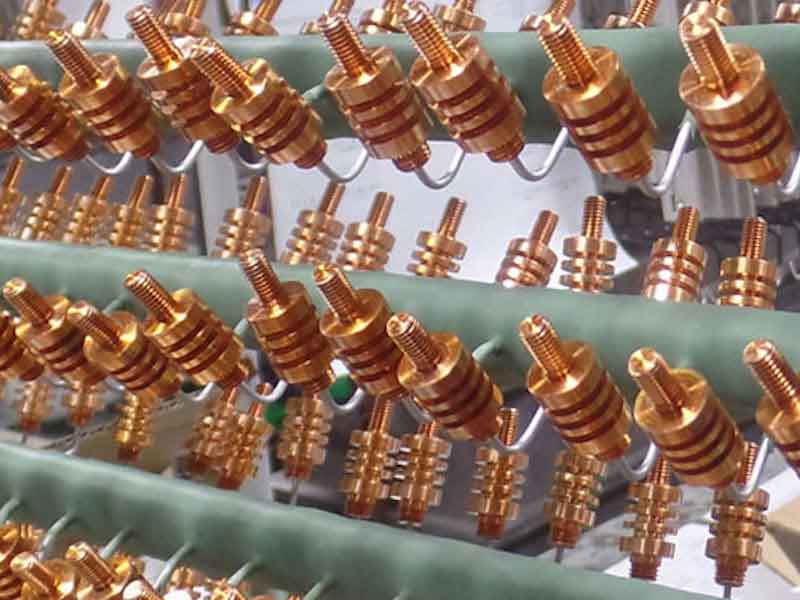

KPW specializes in copper, gold, silver, nickel, tin, and solder plating, as well as electroless nickel on various substrates. They offer rack, barrel, reel-to-reel, and vibratory plating options.

Watch the Video

The reel-to-reel plating method is an efficient and economical process that allows for select deposits of metal. The process can plate strips of manufactured products or reels of raw material before they are stamped into parts. This starts by loading the reels onto a de-reeling station; by using a capstan system, the product is fed through various electroplating processes. At the end of the line is a take-up system that re-spools the material once the appropriate metal finish is achieved. Multiple reels can run with the use of an accumulator, which facilitates a smooth transition between them.

KPW also maintains five separate ovens for metal heat treatment and baking metal parts. The ovens’ temperatures have a maximum range of 1800°F and are digitally controlled for accuracy. All of the shop’s ovens are calibrated on a scheduled basis to ensure dependable daily operation.

On top of heat treating, KPW offers bright dipping, buffing and polishing, cleaning and light degreasing, packaging, passivating, post-treatments, stripping, and ultrasonic cleaning.

Increasing Operational Quality Controls

With an abundance of services offered, Dudenhoeffer says it was imperative to work to automate the process.

With an abundance of services offered, Dudenhoeffer says it was imperative to work to automate the process.

“We have been increasing our quality controls everywhere we can, such as calibrated timers on every tank so that our operators can see the signals that the line is going to place parts in a tank for 30 seconds and pick it up and move it 30 seconds later. Consistency is a key part of quality,” he says.

Dudenhoeffer began “officially” working at KPW in 1996. He actually worked there for many years as a teen and in college, while his father, Larrie Dudenhoeffer — the nephew of Richard Klein, the son of co-founder Francis Klein —was president and owner of the company.

Joe Dudenhoeffer originally went to school to become a doctor but changed fields in college in order to make sure his father’s hard work continued.

“My dad is my hero,” Dudenhoeffer says. “I didn’t originally want to own and run a plating shop, but knowing how much my dad loved this business and how important it was to him, I knew I needed to change directions and come back here to Klein Plating.”

He obtained his undergraduate degree in Business Administration from Gannon University and was hired in 1996 as the buyer for KPW. In December of 2006, Dudenhoeffer — then acting Sales Manager — took over as president of the company, which was also at the same time he was going back to school for a Master’s degree.

“I must have gone bonkers and came up with that crazy idea. Between work and school, I was putting in 16-hour days,” says Dudenhoeffer, who attained his MBA from Penn State in 2008. In 2013, he acquired all of the KPW stock and became the fourth-generation family owner. He remained President of the company as well as assuming the role of CEO and Chairman of its Board of Directors.

Dot Com Crash and Fire Spell Hardship

At the time he took over in 2006, KPW was already reeling after several unfortunate mishaps and a crumbling dot com economy. In the early 2000s, the tech bubble crash cost KPW many of its most profitable customers, including one which declared bankruptcy and left the shop holding a $200,000 invoice for silver alone. It was a devastating time for Dudenhoeffer and his team, as the crash took away most of their business income.

At the time he took over in 2006, KPW was already reeling after several unfortunate mishaps and a crumbling dot com economy. In the early 2000s, the tech bubble crash cost KPW many of its most profitable customers, including one which declared bankruptcy and left the shop holding a $200,000 invoice for silver alone. It was a devastating time for Dudenhoeffer and his team, as the crash took away most of their business income.

“At one point, we had $73 in our bank account,” he says. “I was 26 years old at the time, and I just wasn’t fully prepared for what we were going through. But I learned from my dad to just roll up your sleeves, stay focused and work through it.”

Work through it they did, but almost immediately after they started to get back on their feet, Klein Plating suffered a devastating fire in 2003, resulting in over $1 million in damages and halted operations for over three months.

As Dudenhoeffer and his team worked feverishly to work with the insurance company to get back in operation — “A total nightmare,” he says – the company president and owner also knew he had to salvage his relationships with his top customers to get their parts back into the shop once the doors were fully open.

“I literally went around the county door-to-door to our customers to assure them we were going to be coming back and stronger,” Dudenhoeffer says. “I am extremely proud that we got every one of them back, but those were tough years in the tech crash and the fire. It was not a great way to start out, and I’d be lying if I said I didn’t question my career choices during these trying times.”

Lean and Efficient Operations

One of the things that Dudenhoeffer learned in all of this was to make sure his shop was lean and efficient in its operations. To do that, he had to overcome years and decades of business habits framed by his predecessors and manager, who saw no problem that couldn’t be solved by putting more men on the job.

One of the things that Dudenhoeffer learned in all of this was to make sure his shop was lean and efficient in its operations. To do that, he had to overcome years and decades of business habits framed by his predecessors and manager, who saw no problem that couldn’t be solved by putting more men on the job.

“When I took over, we really had to tear down the way we were doing things and take a different look at how we need to run things operationally,” Dudenhoeffer says. “I came in with a fresh set of eyes, and we made the decision that we were going to start to do things better, and I didn’t care how we got there. It didn’t matter to me how good we already were; we were going to get even better because that is how you grow. We started with the simplest of things, but when we started to improve our processes little by little, it all started to add up. It’s not always fancy technology or large budgets that lead to big changes. Attitude, philosophy, and common sense are extremely powerful tools.”

Of course, Dudenhoeffer has relied heavily on his management team to keep the shop running in top shape over the years and in shaping its new direction through automation and quality assurance.

Tom Dudenhoeffer is the Sales Manager; Scott Cooper the Quality Manager; John Fuller the Production Manager; Zach McQuaid the Resource Manager; Sheila Kern the Personnel Director; Jennifer Davis the Shipping Supervisor; Sandy Zewe the Quality Supervisor; Amanda Wander in Customer Service; Jennifer Hinkler is Sales Assistant; Elizabeth Rula-Monnie, the Lab Supervisor; Jason Schau, the Waste Treatment Supervisor; and Plating Supervisors Dennis Hultberg, Doug Martinez, and Brandon Hodapp.

Doing More With Less

“Our goal is to do more with less,” Dudenhoeffer says. “With the lack of employees we can bring on, we need to become as efficient as we can, while still delivering the services and quality that our customers expect. That is a big challenge, but our team does a great job of meeting it.”

“Our goal is to do more with less,” Dudenhoeffer says. “With the lack of employees we can bring on, we need to become as efficient as we can, while still delivering the services and quality that our customers expect. That is a big challenge, but our team does a great job of meeting it.”

Dudenhoeffer says it is highly rewarding for his team when they find ways to streamline operations without sacrificing the quality and attention to detail that is needed in the parts they finish for customers.

“When you figure out a way to increase efficiency by 25 percent, that is so rewarding,” he says. “Not only are we making a higher profit margin that is good for us, but it also allows us in the future to offer discounts to key accounts and customers in the future, and that is a win-win for everyone.”

Visit https://www.kleinplating.com