Quick. Quality. Inexpensive. You can have two, but you can’t have all three.

We’ve all heard the phrase, but what does it mean when talking about automation, and more specifically in the finishing industry?

Hope DollarhideIt means that the quality and success of a paint automation project are going to depend on what company you select as your automation partner and their ability to audit your process and make recommendations that will suit your business needs. Easy or quick does not necessarily mean quality, and quality does not necessarily mean it was quick and easy.

Hope DollarhideIt means that the quality and success of a paint automation project are going to depend on what company you select as your automation partner and their ability to audit your process and make recommendations that will suit your business needs. Easy or quick does not necessarily mean quality, and quality does not necessarily mean it was quick and easy.

Since 2020 it has been a rollercoaster with the pandemic, the challenges in the economy, a massive labor shortage, and supply chain chaos which has resulted in a huge increase in the demand for automation in virtually every industry.

In a survey by www.FinishingAndCoating.com of powder coating shops, 73% say they use an automated conveyor line in the facility, but only 32% are using robotics to apply coatings. Just over 41% say they want to add robotics to their facility, and 64% say they feel that robotics will help them overcome the lack of a qualified workforce.

Shrinking Labor Market

Currently, there are more jobs than people, which means workers have more freedom with their job selection. Coupled with the large number of people leaving the workforce, this has created a nationwide labor shortage causing companies to struggle to meet production goals.

Currently, there are more jobs than people, which means workers have more freedom with their job selection. Coupled with the large number of people leaving the workforce, this has created a nationwide labor shortage causing companies to struggle to meet production goals.

The finishing industry, in particular, lacks skilled manual sprayers to keep up with demand since workers are retiring at a record pace. The industry is both fortunate and tormented; on the one hand, blessed with the increased activity and demand for products in the market but afflicted by not having enough workers to handle the increased business. Because the issue is now — and not in a few years — companies want a solution today.

How do you solve the shortage of manual sprayers? What will you do if all your manual sprayers retire? Why can’t you find young workers who want to be manual sprayers? These are real dilemmas for painters and coaters, and based on the large number of companies who visited the recent FABTECH trade show, they need immediate solutions before labor shortages impact their ability to remain viable and competitive.

Take a Closer Look at What Automation Can Do

Large scale robot applying liquid paint to automotive components with a bell applicator.A viable solution could be to invest in automation, which is not limited to just robots. It also includes simple machines and reciprocator spray technology. A lot of paint and coating automation lines include reciprocator systems and/or paint robots. A reciprocator machine can be a great investment for manufacturers who have high-mix parts with simple geometry that need to be painted. These types of manufacturers are okay with broad-spectrum paint applications and are happy to make a large investment in reciprocator technology.

Large scale robot applying liquid paint to automotive components with a bell applicator.A viable solution could be to invest in automation, which is not limited to just robots. It also includes simple machines and reciprocator spray technology. A lot of paint and coating automation lines include reciprocator systems and/or paint robots. A reciprocator machine can be a great investment for manufacturers who have high-mix parts with simple geometry that need to be painted. These types of manufacturers are okay with broad-spectrum paint applications and are happy to make a large investment in reciprocator technology.

When it comes to finishing robots, traditionally low-mix, high-volume applications have been the bread and butter of the industry. For example, a plant that paints 1,000 of the same tractors or trucks all day long is a great application, primarily due to a robot’s repeatability. Today, however, robot technology has grown and expanded with new programming techniques that have further simplified the process and allowed customers with high-mix, low-volume parts to enjoy the benefits that robotics can offer.

Launching automation into a paint or powder coating facility can provide a multitude of improvements, such as:

- Increase part throughput and quality of the finish.

- Decrease the amount of material used for painting and coating.

- Address the labor shortage challenges.

- Enhance repeatability by finishing parts the same way every time.

The largest hesitation of manufacturers with little to no experience with automation is the cost associated with installation. However, by selecting to work with an experienced and knowledgeable automation supplier who can provide a detailed ROI, those doubts are easily resolved.

In fact, many plants have been able to achieve a quick ROI based on paint and material savings alone. Robots are also able to work full time 24 hours, seven days a week, running the same programs over and over with no issues or fatigue. This not only reduces the need for manual labor but significantly enhances quality.

A Knowledgeable System Integrator is Essential

Hand-Guidance is an Easy-Teach option that allows programmers to create a path with lead-through-teach style.The key is to select a system integrator who specializes in finishing applications and has extensive knowledge about robots.

Hand-Guidance is an Easy-Teach option that allows programmers to create a path with lead-through-teach style.The key is to select a system integrator who specializes in finishing applications and has extensive knowledge about robots.

There are many companies that specialize in providing automation equipment, but finding one that supports a robot in their lab for demonstrating paint and powder coating applications is worth a second look.

Once new users realize that it’s possible to automate their existing paint booth, they need guidance regarding robot programming and operation. Some say there is not enough information available about what robots can do to improve painting and coating facilities, or they believe that it would only complicate their process.

It’s important to connect with a knowledgeable paint automation expert to provide accurate information and guidance. For example, robotic programming may appear intimidating or daunting, especially to those who have never tried it. But after meeting with system integrators, painters and coaters will learn that today’s user interface is simple and there are many assistance and easy-teach options available.

Once employees are properly trained, a decent painter can become an even better paint robot programmer. Making the switch to automation offers your current and future employees a better environment, increased opportunities for workforce upskilling, and higher wages.

Easy-Teach Tools

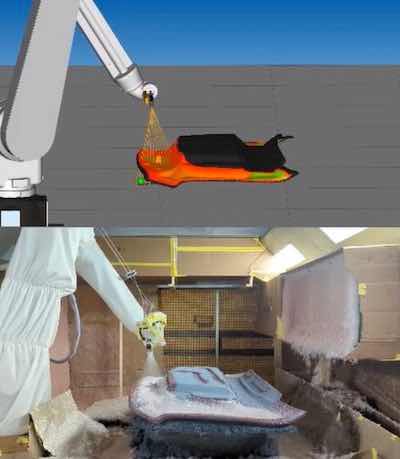

3DV simulated programs can be created and played back offline then easily uploaded to a robot in real-time.There are several easy-teach tools that assist in robotic programming. Easy-teach tools consist of several techniques and technologies that can minimize programming time, and two of those tools are offline 3D simulation programming and scan-to-path artificial intelligence.

3DV simulated programs can be created and played back offline then easily uploaded to a robot in real-time.There are several easy-teach tools that assist in robotic programming. Easy-teach tools consist of several techniques and technologies that can minimize programming time, and two of those tools are offline 3D simulation programming and scan-to-path artificial intelligence.

Offline 3D simulation is PC-based and allows manufacturers to program the robots in an offline setting. This means that the line does not need to be down to program. The controls and operation of the robots on the PC mirror the operations of the robot in the real world. Offline programming allows users to put CAD files in the software and instantly calculate a paint path. From there, users can fine-tune the process and then adjust after using film-build simulations to check the result. This tool is fantastic as it allows the user to adjust the program to their wants while not causing downtime.

Scan-to-path is different from offline 3D simulation programming because it is completely based on artificial intelligence (AI). The system uses cameras and scanners to scan parts, either on a moving line or as a batch or stop station. The AI is then able to take the scan, build a 3D model, smooth it out, and generate a paint program. The robot can take this program and play it back in real-time. This eliminates the need for manual programming. This is an excellent application for manufacturers who need instant and quick paths for high-mix parts.

There are other options for quick programming, including lead-through-teach or hand-guided programming. Lead-through-teaching is attractive because the best manual sprayer can grab the robot and guide it along the path that they think is best. This is appealing to painters and coaters that are first-time automation users because they see that the operation of the robot is much easier than expected. However, today’s programming options — either offline in PC-based simulations or navigating the robot’s teach pendant — are simple and intuitive, and widely accepted by workers who are comfortable using teach pendants and PCs.

Are You Considering Automation?

Given the multitude of challenges that companies face today — including an unprecedented labor shortage — it’s no doubt that many finishers are looking for a quick and easy solution that will increase quality and not break the bank.

Whether you have had experience with automation or have yet to use your first robot, it’s a great time to automate your finishing process.

Then you can answer the questions: Are we ready to automate? Do we need it? Are we prepared to reap the benefits?

Hope Dollarhide is Project Engineer with FANUC America Corporation positioned in the Automotive Component and General Industrial Paint Group. She has a bachelor of science in Robotics Engineering from Lawrence Technological University, and three years of experience in the finishing and coating industry. Dollarhide also has field experience installing large scale robotic systems into paint shops, from Class 8 trucks to single robots in small general industrial job shops. Visit: www.fanucamerica.com/paint