How Justin and Jayna Roy ended up opening a design, metal fabrication, and powder coating company in Eddystone, Pennsylvania, may take some time to explain, but it’s well worth it.

Take one skateboard accident (Justin), mix it with a unique eye for contemporary design (Jayna), and add a whole lot of mushrooms (in their infant daughter Bobbie’s room), and you have all the makings of a modern manufacturing and coating operation, Boonies Design and Fabrication.

“Circumstances and life had different plans for all of us,” says Justin, who is the person behind all the metal fabrication processes, including welding, CNC plasma cutting, tube bending, lathe turning, and milling.

Taking Project from Start-to-Finish

Pat Dunn powder coats customer parts at Boonies Design and Fabrication.In 2021, the couple added powder coating to their services to help with projects they were working on for customers and are now bringing in outside work from companies needing coatings in Eddystone, located about 30 minutes from Philadelphia.

Pat Dunn powder coats customer parts at Boonies Design and Fabrication.In 2021, the couple added powder coating to their services to help with projects they were working on for customers and are now bringing in outside work from companies needing coatings in Eddystone, located about 30 minutes from Philadelphia.

“We really are able to take a project from start to finish in-house,” says Jayna, who learned the powder coating process to assist on the shop floor but has now hired a full-time coater to handle that aspect of the production process.

Boonies works with industrial companies to fabricate custom parts and components to spec, such as furniture, railings, fixtures, and more. They will also design and fabricate custom furniture and fixtures to elevate a residential space, and they are happy to repair and rehabilitate existing metal fixtures from someone’s home, too.

Adding powder coating upped their game with clients and customers who prefer that Boonies handle all the work from start to finish.

“Being able to offer a product or a piece of custom fabrication that’s finished has a lot of appeal to a client,” Jayna says.

An Artist and Skateboarder Meet in California

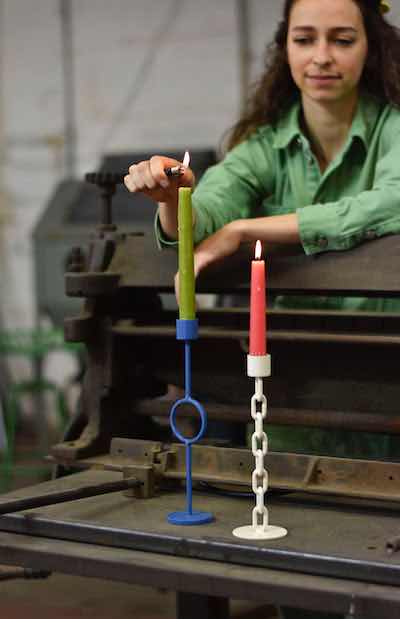

The Roys realized they could continue to make and sell online home décor products such as candlestick holders and other items.But to understand how Boonies came to be starts with looking back at the Roy’s original hopes and dreams in their careers and how they manifested and evolved into design, craftsmanship, and some unbelievable social media exposure that propelled them into what they are doing today.

The Roys realized they could continue to make and sell online home décor products such as candlestick holders and other items.But to understand how Boonies came to be starts with looking back at the Roy’s original hopes and dreams in their careers and how they manifested and evolved into design, craftsmanship, and some unbelievable social media exposure that propelled them into what they are doing today.

Jayna earned an art degree in glass from Temple University’s Tyler School of Art and Architecture several years ago and then moved to California to live with her sister.

A Louisiana native, Justin moved to California to try a career as a professional skateboarder, but a serious injury ended that pursuit. He went to work in Los Angeles building movie sets, where he learned how to weld and fabricate metals.

The two met and began dating and connected their skills by making furniture items for their home and for friends; Jayna came up with the ideas, and Justin used his welding and fabrication talent to put it all together. Soon they turned their hobby into a business and started to sell their artistic creations to shops and individuals.

They soon moved back to Justin’s hometown in Louisiana and expanded the design and fabrication business, as restaurants and several other industries hired them to make signs and other fixtures for them, as well as having a few residential customers.

Pandemic Creates Online Opportunities

Just as things were taking off for them, the pandemic hit in 2020, and the newlyweds began to struggle as the commercial market began to dry up as restaurants and industries had a hard time staying open.

The Roys quickly realized they could continue to make and sell online home décor products such as candlestick holders and other items, and that got them by for several months. Jayna also took the showcasing of her designs and Justin’s craftsmanship on social media, and several major news outlets quickly saw the posts and began publicizing their small company.

Justin had just one caveat for an in-house system: he didn’t want to have anything to do with powder coating. “I said, ‘I’ll do it,’” Jayna says

For example, Vogue magazine highlighted the Boonies’ chain candle stick holder, as did Vice, Cool Hunting, Madewell, and Louisiana Living. But the Roys hit the motherlode when The New York Times picked up on Jayna’s TikTok video of the many mushroom items the couple had made for the nursery of the newly-born Bobbie. Over 750,000 people saw the social media post, and The Times came to the Boonies facility to interview the couple.

By then, Justin and Jayna had packed up and moved to Eddystone, into a 5,000-square-foot space nearby Jayna’s Father’s machine shop, PGA Machine Co., to operate their company, and Boonies Design and Fabrication was off and running again.

But both Jayna and Justin knew that they would need to add powder coating to their services offered to keep production humming and customers happy.

“We moved into the new workspace in March 2021, and we had powder coat up and running by mid-April,” Jayna says. “We invested in a gun and an oven, and we were lucky that we found a sandblaster that someone was giving away. We fixed it up and got it working.”

Be Able to Talk Finishes with Customers

Boonies began working with other manufacturers in their area to handle outside work.She says that customers quickly grew happy with knowing that not only was Boonies fabricating their product, but that they could also talk about the finish with them, too.

Boonies began working with other manufacturers in their area to handle outside work.She says that customers quickly grew happy with knowing that not only was Boonies fabricating their product, but that they could also talk about the finish with them, too.

“With some of the fabrication stuff, the customers maybe didn’t understand all that went into it, and it might not excite them as much as how are we going to finish this project and make it look like a polished, finalized item,” Jayna says. “Instead of, ‘Now you have to go take it to a powder coater,’ we could say ‘we do it all.’ We’ve seen how that has really helped our fabrication business as well, being able to get something started from scratch and to finish it.”

Justin says they had very little knowledge about powder coating other than what they learned from a friend’s shop, Fry’s Coatings, in Louisiana that was doing the project work for them. But he knew that because Boonies was small quantity to a lot of powder coaters, there would be issues on getting parts back in time.

“We were a very small part of their business, so turnaround time started to become a little longer,” Justin says. “That was a big reason why we wanted to bring it in-house; having control over the entire process and not pressuring my friends into doing it all the time. I grew tired of always saying, ‘Come on buddy, I really need you to get this done for me.’”

But Justin had just one caveat for an in-house system: he didn’t want to have anything to do with powder coating. His forte is fabricating and creating, and he wanted to leave the coating part up to someone else.

Learning by Making Mistakes

“I said, ‘I’ll do it,’” Jayna says. “I taught myself how to do it, and we called our friends at Fry’s, and they gave us some tips and pointers; that was really helpful.”

“I said, ‘I’ll do it,’” Jayna says. “I taught myself how to do it, and we called our friends at Fry’s, and they gave us some tips and pointers; that was really helpful.”

She also spent a considerable amount of time learning where most everything else is taught: by watching YouTube videos to see how other shops were doing it and by reading articles. But Jayna admits that wasn’t something she would recommend to most newcomers to the coating field.

“We really learned by making mistakes,” she says. “Then we’re like, ‘Alright, let’s figure this out.’ So we put our heads down and figured it out.”

Says Justin: “I don’t think either of us has been shy of a challenge. We’re okay with making mistakes; we just jump in and figure out how to swim along.”

Justin made their first powder coating booth, and they purchased an oven to cure the parts and a gun to apply the coatings. Since the first began coating in 2021, they have rebuilt the spray booth and invested in better equipment to get better finishes.

“We got some recommendations from our buddies in Louisiana for a good starting point on equipment,” Justin says. “Our gun does have KV and ohms control, plus a vector wave control for Faraday areas. I definitely have started to see the need for potentially upgrading the gun at some point soon.”

Hiring a Powder Coating Manager

Jayna and Justin Roy, along with powder coat manager Pat Dunn.And when Boonies began working with other manufacturers in their area to handle outside work, they decided to hire a powder coating manager. Pat Dunn, who had no prior experience in powder coating, now handles the inside and outside coating projects, and they hope to grow that side of the business as well.

Jayna and Justin Roy, along with powder coat manager Pat Dunn.And when Boonies began working with other manufacturers in their area to handle outside work, they decided to hire a powder coating manager. Pat Dunn, who had no prior experience in powder coating, now handles the inside and outside coating projects, and they hope to grow that side of the business as well.

“He has a really great attention to detail, and he has picked it up pretty well,” Jayna says. “He’s learning and recommending how we could adjust this and that and how it would help with orange peel, or let’s try outgassing these parts a little bit longer and see if that helps.”

Overall, the Roys says adding the in-house powder coating system has been a huge benefit to their business, and they are glad they have made the investment in the technology and equipment.

“When you know how to powder coat, you can really talk about that with a client,” Jayna says. “We can tell them the benefits, outline limitations and options. For example what a topcoat or zinc primer will do if the project is going to be outside. I think it helps the client get excited and feel comfortable and confident working with us.”