AR Powder Coating’s Tony Sclafani has his own take on what the 5P idiom means when it comes to running his company’s powder coating division.

Tony SclafaniWhile some may be used to the “Proper Planning Prevents Poor Performance” saying when it comes to operations, Sclafani has a different perspective.

Tony SclafaniWhile some may be used to the “Proper Planning Prevents Poor Performance” saying when it comes to operations, Sclafani has a different perspective.

“For us, it is ‘Proper Pretreatment Prevents Poor Performance,’” says the Vice President and General Manager of the family-run Las Vegas AR Iron facility, which also includes an in-house powder coating operation, AR Powder Coating.

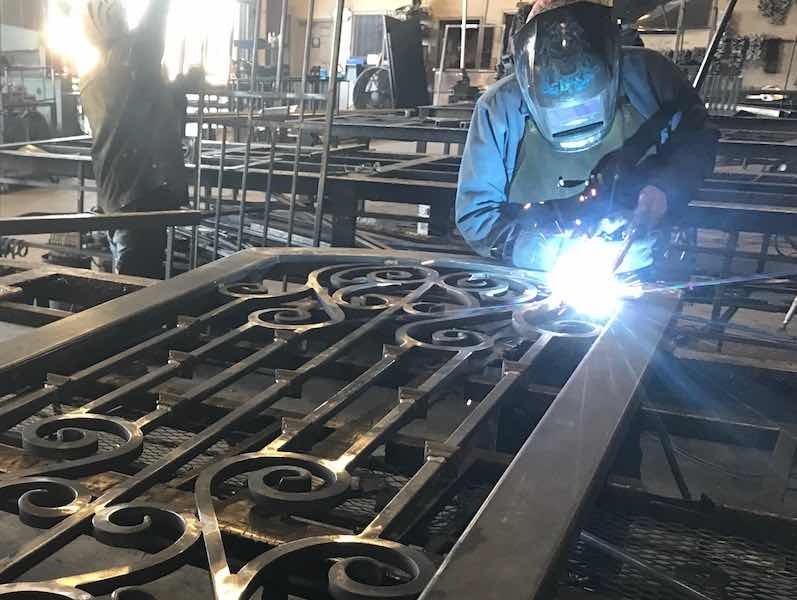

“We’re always looking to differentiate ourselves because every shop basically does the same thing, whether it’s an ornamental or powder coating,” Sclafani says. “Anybody can pick up a welder, and anybody can pick up a powder coat gun. But it’s how you do it and the steps you take. We won’t take shortcuts. I for sure will not.”

Continually Improving Upon its Operations

ARPC has over 20,000 square feet of production space and 20 employees.It is that approach that has led AR Iron — which was started by Sclafani’s parents, Fred and Sylvia, in 1989 — to continually improve upon its operations, standards, and procedures when it comes to its powder coating division.

ARPC has over 20,000 square feet of production space and 20 employees.It is that approach that has led AR Iron — which was started by Sclafani’s parents, Fred and Sylvia, in 1989 — to continually improve upon its operations, standards, and procedures when it comes to its powder coating division.

They have over 20,000 square feet of production space and 20 employees, so drilling home to everyone the quest for quality and perfection is a non-stop endeavor of Sclafani and his management team.

“When I was younger, my father told me that there are many other people who do the same thing that we do,” he says. “So getting a customer to come to our shop, we felt like our services needed to have something more: quality, timeliness, and real dedication to each and every customer that we had.”

That led AR Iron’s powder coating division to seek AAMA 2604 and AAMA 2605 certifications, which they recently earned. The company is one of the few companies in the western U.S. to pass the rigorous testing set forth by the American Architectural Manufacturers Association (AAMA) to offer AAMA 2604 and AAMA 2605-compliant powder coatings to architects, constructors, and building owners.

Offering AAMA 2604 and 2606 Guarantees

Tony Sclafani's parents started AR Iron in 1989, and added powder coating several years later.The distinction sets them apart: the AAMA 2604 coating offers AR Iron’s clients a 5-year warranty, and the AAMA 2605 coating provides a substantial 10-year warranty.

Tony Sclafani's parents started AR Iron in 1989, and added powder coating several years later.The distinction sets them apart: the AAMA 2604 coating offers AR Iron’s clients a 5-year warranty, and the AAMA 2605 coating provides a substantial 10-year warranty.

“The AAMA certification is another step in the right direction to continue developing our business and becoming a leading applicator,” Sclafani says.

The certification process required their powder-coated samples to undergo extensive testing, including salt spray and humidity chamber tests. These evaluations assess adhesion, gloss, and overall powder coating performance, guaranteeing resilience and longevity.

For AR Powder Coating, that means coatings that will last a long time and withstand tough environments. Sclafani says it has been something they have been doing for many years, even before the AAMA certifications came to fruition.

“We built a line and threw in a conveyor system, but we didn’t know anything about what we were doing. But we learned, and we kept pushing forward."

“We have a periscope we coated that’s down in the wharf in San Francisco, 50 feet from the ocean,” he says. “It’s been there 10 plus years now, and it still looks fabulous to this day. So when you have successes like that, it tells me we’re on the right track, and it all begins with pretreatment.”

AR Iron is a family business that has grown from a small ornamental iron shop to a world-class iron, powder coating, and media blasting company for Henderson and Las Vegas. The company grew from doing multi-family unit ironworks and started doing stairs, apartment buildings, condominiums, and other larger projects.

Added Powder Coating in 2005

In 2005, AR Iron started looking at providing a better finish for its customers. They were applying an oil-based enamel and decided to look into adding a powder coating service.

In 2005, AR Iron started looking at providing a better finish for its customers. They were applying an oil-based enamel and decided to look into adding a powder coating service.

“We built a line and threw in a conveyor system, but we didn’t know anything about what we were doing,” Sclafani says. “But we learned, and we kept pushing forward. We are always trying to improve ourselves and look at the next step to get better.”

One of those ways to improve was getting training from the Powder Coating Institute and through Chemicals Coaters Association International, where Sclafani and his team became very active in classes and meetings. Sclafani eventually became a driver of the CCAI Las Vegas chapter and now serves as the president of the national board.

“Those two organizations have been extremely helpful with not only ourselves but growing the knowledge base and the educational side of the industry,” he says. “It’s been a huge benefit to continually train your staff.”

When AR Powder Coating went after the AAMA certification, they worked closely with their reps at Tiger Drylac powder coatings to help them get their coating system ready to meet the strenuous demands of the requirements.

“We’ve taken all our people in groups and put them into those classrooms, and we tell them, ‘Hey, this is why we do these things this way,’”

“They gave us suggestions and ideas as to how we can be successful to meet the certifications,” Sclafani says. “Went through the processes of the alkaline testing, the phosphates, the core bond, and all the different applications. It was very helpful.”

When AR Powder Coating applied for the certification, they sent their test panels in for scrutiny and then waited. And then waited even longer. In fact, several months went by while the AAMA lab tested the samples and then called Sclafani with good and bad news.

Second Try Was the Charm

The shop passed the AAMA 2604 testing but failed the AAMA 2605 at the 11th hour when salt-spray testing was completed. Needless to say, Sclafani and his team were disappointed but not discouraged.

The shop passed the AAMA 2604 testing but failed the AAMA 2605 at the 11th hour when salt-spray testing was completed. Needless to say, Sclafani and his team were disappointed but not discouraged.

“It hurt because we did everything exactly the way it was supposed to be done, and even the laboratory couldn’t figure out what went wrong,” he says. “It might have been something that got in the RO and the rinse, but we wanted to test again. We did the exact same test, except we made just a little tweak, and that was great because our chemical guys worked with us.”

A few weeks later, AR Powder Coating was notified that it had passed the 2605 requirements.

“With flying colors,” Sclafani says.

AR Powder Coating has seen the success it has had because of the constant training, Sclafani says, as well as a commitment to providing the best coating they possibly can. He says his team has bought into the training he puts them through.

“We’ve taken all our people in groups and put them into those classrooms, and we tell them, ‘Hey, this is why we do these things this way,’” he says. “And they’ve bought into it. Of course, there is always human error, and sometimes a guy comes in and he says, ‘I missed it, or I screwed up.’ But that happens. With the procedures that we follow, everybody has bought into it because they want to provide that level of service to our customers.”

Training and Upgraded Equipment Spell Success

AR Iron is not only keeping its team trained on the best practices in powder coating, but it also invests in newer equipment or upgrades when it is available. They just recently worked with Parker Ionics on new equipment that sends a message to their team that the company is investing in the best tools for their team.

AR Iron is not only keeping its team trained on the best practices in powder coating, but it also invests in newer equipment or upgrades when it is available. They just recently worked with Parker Ionics on new equipment that sends a message to their team that the company is investing in the best tools for their team.

“We changed out our analog gun controllers to all-digital gun controllers, and we put in all new reciprocator and a new wash system with now a six and seven stage pretreatment,” Sclafani says. “Parker Ionics came in and just did a phenomenal job with these little tweaks from our original installation. It makes a big difference.”

AR Powder Coating currently has a 600-foot conveyor line that can handle 20 load bars, which allows them to coat parts that are eight feet tall, two feet wide, and 20 feet long. They have full powder recovery and reclaim and have a batch system that is 12 feet by 12 feet by 35 feet deep.

“I would love to have another one right now because the demand is increasing more and more,” Sclafani says.

About 50% of their business is their own work at AR Iron, and the other half comes from outside manufacturers. While they are busy every day, Sclafani says he expects the company to grow even more if the economy holds steady.

“I think eventually down the road, either another batch system or another small conveyor system might be beneficial to us,” he says. “It all just depends on our workload, but Southern Nevada seems to be growing in the needs. A lot of Californians are moving out here, and a lot of manufacturing, too. The future’s bright in Southern Nevada.”