The charging characteristics of coating powders were improved for both corona-charging and tribocharging-type spray guns.

The blow-off measurements showed that the charge-to-mass ratio of coating powders deposited on the substrate was larger than that of undeposited powders for both types of spray guns. The charge-to-mass ratio of the coating powders was increased by adding a pair of auxiliary electrodes to the corona-charging spray gun.

Free ions from the corona-charging spray gun were decreased by applying a magnetic field in the spraying space. The polymer tube of a tribocharging spray gun that contained a negative charge control agent was able to charge all the coating powders sufficiently positive.

1. Introduction

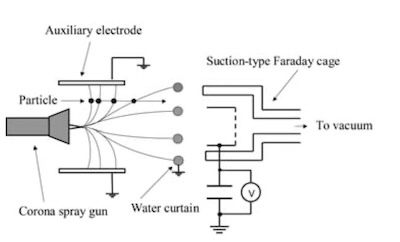

Figure 1. Corona-charging electrostatic powder coating system and lines of electric force in the spraying space (top view).Electrostatic powder coating is an environmentally friendly technology, which emits no volatile organic compounds (VOC) [1]. The electrostatic powder coating can be classified into two types, corona-charging and tribocharging [2]. However, both techniques have several problems. For example, charging efficiency of coating powders is sometimes not sufficiently high in both techniques. A corona-charging type spray gun can be applied to any kinds of coating powder but this technique has the disadvantages of Faraday cage effect and back-ionization, which deteriorate the coating layer performance. On the other hand, a tribocharging type spray gun does not has these two disadvantages, but application of this technique is limited to a few coating powders due to the limited triboelectric series of materials currently available.

Figure 1. Corona-charging electrostatic powder coating system and lines of electric force in the spraying space (top view).Electrostatic powder coating is an environmentally friendly technology, which emits no volatile organic compounds (VOC) [1]. The electrostatic powder coating can be classified into two types, corona-charging and tribocharging [2]. However, both techniques have several problems. For example, charging efficiency of coating powders is sometimes not sufficiently high in both techniques. A corona-charging type spray gun can be applied to any kinds of coating powder but this technique has the disadvantages of Faraday cage effect and back-ionization, which deteriorate the coating layer performance. On the other hand, a tribocharging type spray gun does not has these two disadvantages, but application of this technique is limited to a few coating powders due to the limited triboelectric series of materials currently available.

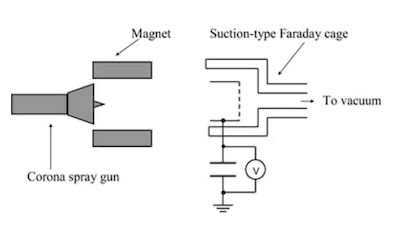

Figure 2. Application of a magnetic field to the corona-charging spray gun (top view).We tried to increase charging efficiency of coating powders and to decrease free ions in a corona- charging spray gun by using a pair of external electrode and a magnetic field respectively. We also tried to apply charge control agents (CCA) to modify the tribocharging characteristics of coating powders, which are often used to control polarity and charge-to-mass ratio in the tribocharging of toners in electrophotography [3].

Figure 2. Application of a magnetic field to the corona-charging spray gun (top view).We tried to increase charging efficiency of coating powders and to decrease free ions in a corona- charging spray gun by using a pair of external electrode and a magnetic field respectively. We also tried to apply charge control agents (CCA) to modify the tribocharging characteristics of coating powders, which are often used to control polarity and charge-to-mass ratio in the tribocharging of toners in electrophotography [3].

2. Experimental

2.1. Corona-charging spray gun

A conventional corona-charging type of spray gun was used in this study and the charge-to-mass ratio, Q/M, of the coating powders was measured by using a suction type Faraday cage as shown in figure 1. A water curtain was used to prevent collection of free ions by the Faraday cage. The Q/M of the coating powders was also measured by the blow-off method.

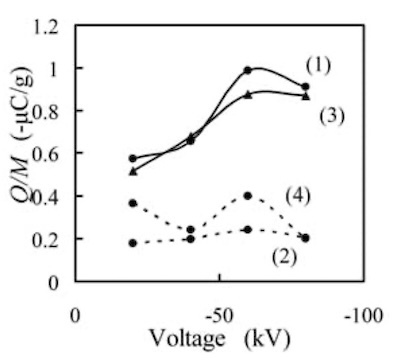

Figure 3. Charge-to-mass ratio, Q/M, of coating powders as a function of voltage applied to the corona spray gun; (1) polyester deposited, (2) polyester undeposited, (3) epoxy deposited, (4) epoxy undeposited.In order to increase Q/M of the coating powders, a pair of external auxiliary electrode was placed at both sides of the space between the spray gun and the Faraday cage as shown in figure 1. The distance between the spray gun and the Faraday cage was 40cm. A pair of metal mesh or metal plate (20×20cm2) was used as the auxiliary electrodes as shown in figure 1, and the separation between the electrodes was variable.

Figure 3. Charge-to-mass ratio, Q/M, of coating powders as a function of voltage applied to the corona spray gun; (1) polyester deposited, (2) polyester undeposited, (3) epoxy deposited, (4) epoxy undeposited.In order to increase Q/M of the coating powders, a pair of external auxiliary electrode was placed at both sides of the space between the spray gun and the Faraday cage as shown in figure 1. The distance between the spray gun and the Faraday cage was 40cm. A pair of metal mesh or metal plate (20×20cm2) was used as the auxiliary electrodes as shown in figure 1, and the separation between the electrodes was variable.

2.2. Tribocharging spray gun

The charging characteristics of coating powders by a tribocharging type spray gun was modified by incorporating a CCA into the inner polymer tube of the spray gun. A polyvinylbutyral layer (60mm in thickness) containing a CCA was prepared on a thin metal sheet by casting method, and then rolled up into a tube (1cm in inner diameter, 90cm in length), and the tube was used as a laboratory-made tribocharging spray gun instead of a real one. Two types of CCA, positive and negative, were used, and their concentrations in the polymer layer were variable.

2.3. Coating powders

Several kinds of commercial coating powder, made of nylon, epoxy, polyester, etc., were used in this study. The mean diameters of all the powders were in the range of 20–30mm.

3. Results and discussion

3.1. Q/M of deposited and undeposited powders

Figure 4. Amount of free ions collected at the Faraday cage for 10s for the corona spray gun (-40kV) as a function of magnet separation.First, the charge-to-mass ratio, Q/M, was measured by the blow-off method for coating powders deposited and undeposited on the substrate when using the corona spray gun. For these measurements, an aluminum plate (30×30cm2) was placed perpendicular to and 30cm apart from the corona spray gun. A second plate, which was used to collect the undeposited powder, was placed horizontally in the lower space between the corona spray gun and the perpendicular plate. The results are given in figure 3. It was confirmed that coating powders deposited onto the substrate charged sufficiently, while undeposited powders were weakly charged. Similar results were obtained for the tribocharging spray gun. These results are quite reasonable and indicate that a sufficiently high charging of the coating powders is necessary for high transfer efficiency.

Figure 4. Amount of free ions collected at the Faraday cage for 10s for the corona spray gun (-40kV) as a function of magnet separation.First, the charge-to-mass ratio, Q/M, was measured by the blow-off method for coating powders deposited and undeposited on the substrate when using the corona spray gun. For these measurements, an aluminum plate (30×30cm2) was placed perpendicular to and 30cm apart from the corona spray gun. A second plate, which was used to collect the undeposited powder, was placed horizontally in the lower space between the corona spray gun and the perpendicular plate. The results are given in figure 3. It was confirmed that coating powders deposited onto the substrate charged sufficiently, while undeposited powders were weakly charged. Similar results were obtained for the tribocharging spray gun. These results are quite reasonable and indicate that a sufficiently high charging of the coating powders is necessary for high transfer efficiency.

3.2. Application of auxiliary electrodes to corona-charging spray gun

As a whole, the charge-to-mass ratio, Q/M, of the coating powders used in this study was in the range of 0.5 to 2 μC/g depending on the kind of powder and the operating condition of the corona-charging type spray gun. The Q/M was changed by placing a pair of external grounded auxiliary electrode in the space between the spray gun and the Faraday cage. Variations in the Q/M of an epoxy-polyester coating powder using the pair of electrodes are given in table 1. The Q/M was changed with spacing of the external electrodes for both the metal plate and metal mesh, and the maximal value (1.32 times) was obtained at the electrodes spacing of 30cm for the metal mesh electrodes. When the electrodes were not grounded, the increase in Q/M was less than that when grounded. When a pair of insulating plate was used instead of metal electrodes, the Q/M of coating powders was decreased.

Table 1. Changing factors in Q/M of epoxy-polyester powder by external auxiliary electrodes.

| Electrode | 40 cm | 30 cm | 20 cm | 10 cm |

| Metal plate | 1.21 | 1.27 | 0.73 | 0.37 |

| Metal mesh | 1.14 | 1.32 | 0.85 | 0.41 |

Corona voltage: -75kV

The increase in Q/M by the external auxiliary electrodes can be attributed to the modification of the lines of electric force in the space between the spay gun and the Faraday cage. All the lines of electric force start from the pin electrode of the corona spray gun (when a positive potential is applied) and terminate at the grounded water curtain and the Faraday cage. The external electrodes modify the lines of electric force. Thus, some lines of electric force terminate at the external electrodes as shown in figure 1, which suggests an increase in opportunities for collision between the coating powder particles and corona ions.

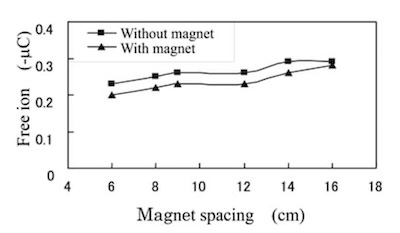

3.3. Application of magnetic field to corona-charging spray gun

In order to decrease the free ions arriving at the Faraday cage, a pair of magnet was placed at the outlet of the corona spray gun as shown in figure 2. Only air was fed into the corona spray gun in this measurement. The amount of free ions collected in the Faraday cage for 10s as a function of the separation of the magnets are shown in figure 4. It can be confirmed that the magnetic field bent the path of the free ions by Lorentz force and decreased the number of free ion directing toward the Faraday cage.

3.4. Modification of charging of tribocharging spray gun

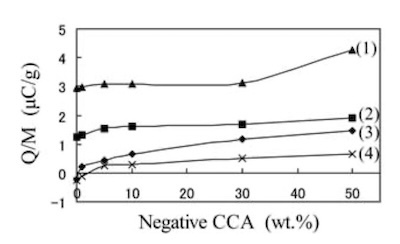

Figure 5. Charge-to-mass ratio, Q/M, of coating powders as a function of negative-type CCA concentration incorporated into the polymer layer; (1) nylon, (2) epoxy, (3) polyester, (4) epoxy-polyester.The values of the Q/M of the coating powders made by the laboratory-made tribocharging spray gun, whose inner tube contains a negative CCA, are shown for several coating powders in figure 5. The polyester and epoxy-polyester coating powders were tribocharged weakly negative with the CCA-free polyvinylbutyral. However, the tribocharging polarity of both powders changed to positive with incorporation of 5wt% of a negative CCA into the polyvinylbutyral. Furthermore, the Q/M increased with an increase in concentration of the negative CCA for all the coating powders. A negative CCA tribocharges itself strongly negatively and give a positive charge to materials which come into contact with it. The results of figure 5 confirms that the negative CCA used in this study works normally and gives sufficiently positive tribocharge to all the coating powders.

Figure 5. Charge-to-mass ratio, Q/M, of coating powders as a function of negative-type CCA concentration incorporated into the polymer layer; (1) nylon, (2) epoxy, (3) polyester, (4) epoxy-polyester.The values of the Q/M of the coating powders made by the laboratory-made tribocharging spray gun, whose inner tube contains a negative CCA, are shown for several coating powders in figure 5. The polyester and epoxy-polyester coating powders were tribocharged weakly negative with the CCA-free polyvinylbutyral. However, the tribocharging polarity of both powders changed to positive with incorporation of 5wt% of a negative CCA into the polyvinylbutyral. Furthermore, the Q/M increased with an increase in concentration of the negative CCA for all the coating powders. A negative CCA tribocharges itself strongly negatively and give a positive charge to materials which come into contact with it. The results of figure 5 confirms that the negative CCA used in this study works normally and gives sufficiently positive tribocharge to all the coating powders.

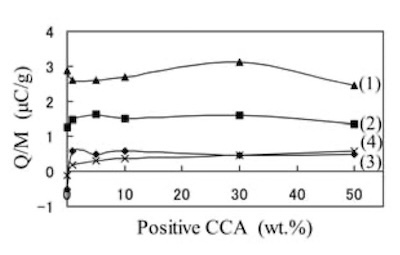

The results of incorporating a positive CCA are shown in figure 6. Contrary to the negative CCA, the positive CCA did not charge all the coating powders negatively. In other words, the positive CCA used in this study did not work normally. It is generally known that the performance of the positive CCA is inferior to that of the negative CCA when used for toners. In addition, the particle sizes of the negative and positive CCAs used in this study are about less than 10mm and 5 mm, respectively. Large particles of CCA can appear partially on the surface when incorporated into a polymer layer, while small particles bury almost completely in particle size of the positive CCA are the reasons the polymer layer. The weak performance and small for the inferior performance of the coating powders.

4. Conclusion

Figure 6. Charge-to-mass ratio, Q/M, of coating powders as a function of positive-type CCA concentration incorporated into the polymer layer; (1) nylon, (2) epoxy, (3) polyester, (4) epoxy-polyester.The charging characteristics of coating powders spray guns and the following results were obtained.

Figure 6. Charge-to-mass ratio, Q/M, of coating powders as a function of positive-type CCA concentration incorporated into the polymer layer; (1) nylon, (2) epoxy, (3) polyester, (4) epoxy-polyester.The charging characteristics of coating powders spray guns and the following results were obtained.

- The charge-to-mass ratio of coating powders deposited on the substrate is larger than that of undeposited powders for the corona-charging spray gun.

- The charge-to-mass ratio of coating powders was increased by placing a pair of external auxiliary electrode for the corona-charging spray gun.

- Free ions arriving at the substrate from the corona-charging spray gun can be decreased by applying a magnetic field in the spraying space.

- The polymer tube of a tribocharging spray gun, containing a negative CCA, charged all the coating powders used in this study sufficiently positive.

Manabu Takeuchi is with the Department of Electrical and Electronic Engineering, Ibaraki University, Nakanarusawa, Hitachi, 316-8511 Japan. Reach him at takeuchi@ee.ibaraki.ac.jp.

Acknowledgment: The author would like to thank Professor Chin-Che Tin of Auburn University for his critical reading, kind suggestion and improvement of the language in the manuscript. This work was supported in part by Kyoto Prefecture Collaboration of Regional Entries for the Advancement of Technology Excellence, JST.

References

[1] Bailey A G 1998 J. Electrostatics 45 85

[2] Dastoori K, Makin B, Tan G L 2005 J. Electrostatics 63 545

[3] Shimada A, Anzai M, Noguchi K 1985 J. Imaging Sci. 20 209