In a past year where the medical industry and manufacturing crossed paths so many times, the people at Advanced Industrial Coatings are looking optimistically at what the new year might bring them.

Dave ArneyWith the pandemic raising awareness about reshoring many manufacturing processes related to the medical industry, AIC certainly sees potential in that growth area. They already have coated parts for medical suppliers Stryker, Philips, GE, and others.

Dave ArneyWith the pandemic raising awareness about reshoring many manufacturing processes related to the medical industry, AIC certainly sees potential in that growth area. They already have coated parts for medical suppliers Stryker, Philips, GE, and others.

“This past year, in dealing with the COVID-19 challenges, we have looked at our direction as a company,” says Dave Arney, AIC’s Chief Operating Officer. “To start with, our people and their health are so important. Employee satisfaction and motivation are areas we will continue to work on. We also feel that the medical industry has played an important role in our success, and we plan to continue to work in this direction.”

The main industries AIC provides coatings to are semi-conductor, medical, food industry, and construction, as well as a smaller variety of other industries. Over the years, the Stockton, California, company has provided coatings for major automotive companies, aerospace companies, and many food processing companies.

Steve HockettTesla, Ford, and Lam Research are just a few of the companies that AIC has worked for, and they receive rave reviews from many of them.

Steve HockettTesla, Ford, and Lam Research are just a few of the companies that AIC has worked for, and they receive rave reviews from many of them.

Uncompromising Quality

“When we entered into a new product line with very stringent painting and coating specifications, we searched the entire west coast for a vendor and selected AIC,” says Andy Lyons with FMC Technologies, which produces equipment for exploration and production of hydrocarbons.

“They were recommended to us by a paint manufacturer’s local representative, and they flew through the initial audit and qualification process with ease,” Lyons says. “Their delivery and pricing are great, and the quality is uncompromising. We couldn’t be happier.”

AIC provides Teflon coatings to many different industries and also coat using xylan coatings, halar, nylon 11, and powder coatings in a 46,000 square foot facility that is broken up into four areas:

- A conveyor line where they do mainly powder coating to thousands of parts at a time.

- A batch area where they have seven ovens and six booths where they apply both liquid and powders, which include Teflon, halar, nylon 11, and xylans.

- They have a controlled environment room where they coat parts that need a little more attention and in a cleaner environment.

- A prep area where they burn, sandblast, and strip parts to ensure proper adhesion before coating.

AIC recently added two new batch ovens to accommodate additional semi-conductor jobs. We also added two coating booths to go along with the two new ovens. During the past year, they also added a solar system with over 1000 solar panels.

New Hoist Crane and Other Expansions

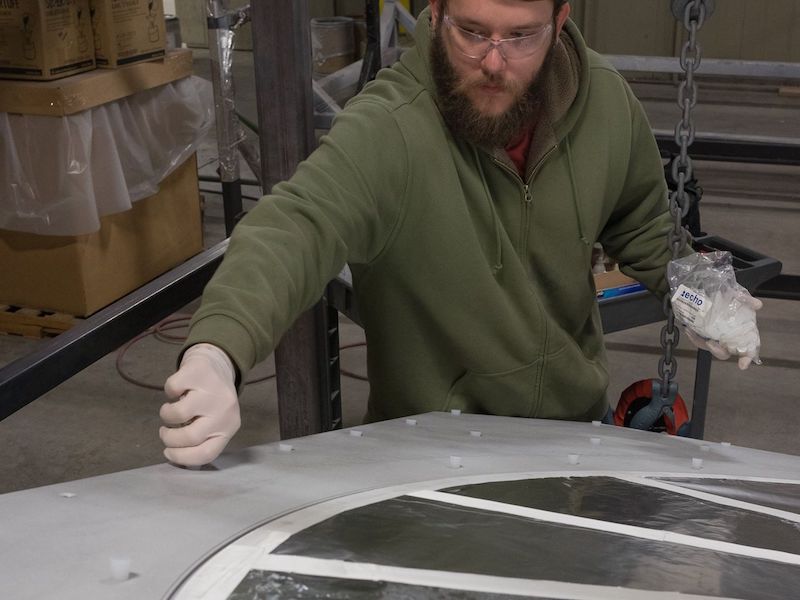

Tesla, Ford, and Lam Research are just a few of the companies that AIC has worked.“The next expansion we have discussed has involved a much larger controlled environmental room to accommodate both medical devices as well as difficult to coat semi-conductor parts,” says Steve Hockett, AIC Vice President. “To accommodate larger parts, we have already added a new hoist crane with a movable lift.”

Tesla, Ford, and Lam Research are just a few of the companies that AIC has worked.“The next expansion we have discussed has involved a much larger controlled environmental room to accommodate both medical devices as well as difficult to coat semi-conductor parts,” says Steve Hockett, AIC Vice President. “To accommodate larger parts, we have already added a new hoist crane with a movable lift.”

AIC prides itself in applying fluoropolymer coatings and coating difficult parts that others cannot do or will not try. Hockett says being ISO 9001-2015 certified since 2004 has enabled them to establish themselves as a high-level quality minded company.

“We also feel that our quality team has been invaluable in making sure that customer reworks are almost non-existent,” he says. “Having a team that really cares is definitely the key.”

AIC was started by Arney in 1985. He was actually looking to buy a coating company since that was the business he had been employed in and enjoyed working with coatings. Unfortunately, locating a seller was not working out.

Ron Cymanski, AIC President, and Arney were longtime friends and had discussed joining forces in a coating company. While not in the industry, Cymanski was knowledgeable in business and understood very well the costs and net worth of a business.

At dinner one evening with their spouses, Cymanski and Arney presented the idea of joining together to start a new coating company, and AIC was formed. Arney had over 12 years of experience in fluoropolymer coatings and a large variety of other coatings, and it was decided that he should head up the company. Mariann Arney serves as Secretary/Treasurer, and JoAnn Cymanski oversees Marketing.

Experience Crew Brings Value

The main industries AIC provides coatings to are semi-conductor, medical, food industry, and construction.Cymanski and Arney hired Steve Hockett to serve as Vice President of Production, overseeing 42 full-time employees and are running one shift.

The main industries AIC provides coatings to are semi-conductor, medical, food industry, and construction.Cymanski and Arney hired Steve Hockett to serve as Vice President of Production, overseeing 42 full-time employees and are running one shift.

“We pride ourselves in that most of our employees have been with us for 15 plus years,” Hockett says. “It gives us a strong competitive edge. Their knowledge is invaluable.”

Hockett says that, in most cases, they have been working with the same suppliers for 35 years and have developed excellent relationships. They include PPG’s Whitford, Intech Services, Cardinal Powder, Arkema materiant, and Solvay Solexis for the halar products.

“We have been coating parts for many customers and for years with a powder coating developed in-house mixed with a combination of PTFE and powder,” Hockett says. “This allows the lubricity of a PTFE but the durability of a powder. We are quite proud of how this has added to our menu of coating materials as well as to our business.”

A typical day at AIC could be coating wah wah pedals for guitars, as the shop often handles 5,000 of those in a single day, usually applying a black wrinkle color in addition to candy apple red or purple.

They also coat electrical boxes in bright yellow for safety, as well as computer shelving and earthquake retrofit parts, for which they apply Glyde Coat, AIC’s proprietary lubricious coating that is a cost-efficient powder PTFE blend.

“It’s so the parts can slide as a building moves,” Hockett says. “We put the same coating on wheelchair parts so the seat can slide up and down easily. It’s a coating that is slippery, but also hard and durable.”

465-Foot Line With 4-Stage Wash

AIC has coated parts for medical suppliers Stryker, Philips, GE, and others.The AIC lines started out like a lot of other conveyor lines for coating applications, but over the years, they have developed it quite a bit. It’s a 465-foot line that Hockett says the AIC team has really perfected the wash cycle, which is a four-stage iron phosphate wash.

AIC has coated parts for medical suppliers Stryker, Philips, GE, and others.The AIC lines started out like a lot of other conveyor lines for coating applications, but over the years, they have developed it quite a bit. It’s a 465-foot line that Hockett says the AIC team has really perfected the wash cycle, which is a four-stage iron phosphate wash.

“The final rinse – the DI rinse – the parts per million are so minimal that the parts are incredibly clean,” he says. “Just one or two parts per million.”

Arney says AIC is proud of the work they perform for U.S. manufacturers and knowing the role they play in the manufacturing process has been inspiring over the years.

“Many times over, we have been able to solve a major problem for a customer,” Arney says. “That is always the goal.”

Visit https://aic-coatings.com