Brothers Phil and Alex Ohl have the finishing industry in their blood. Their dad Jeff and step-mom Colleen, not so much.

But when Phil and Alex heard about an opportunity to purchase a powder coating operation in Dayton, Ohio, from its retiring owner, the chance was just too good to pass up.

With Colleen and Jeff as owners, the Ohl brothers opened for business Old North Powder Coat Co. in July 2020, witnessing a dream come true to stay in the finishing and coating business and be their own bosses as managers of the facility.

“We jumped on it,” Phil says of the chance to run their own coating business. “We just needed that help financing the dream.”

Advice, Consulting, and Financial Backing

Collen is the primary owner of Old North Powder Coat, making it a woman-owned business of a 20,000 square feet fully-equipped powder coating facility on four acres in the middle of the Old North section of Dayton.

Collen is the primary owner of Old North Powder Coat, making it a woman-owned business of a 20,000 square feet fully-equipped powder coating facility on four acres in the middle of the Old North section of Dayton.

“We made the pitch to our dad and stepmother, and also for their purchasing advice, new business consulting, and financial backing,” Alex says. “After a couple of months of research, planning, and negotiations, an offer was made, and the purchasing deal closed.”

Before the ink dried on the purchase contract, the real work began.

“A ton of clean-up immediately began, as well as a vision, fresh eyes, and minds,” Phil says. “It took two months, four massive dumpster loads, and a lot of sweat equity to get the place up to snuff.”

The facility has a 25-feet long by 10-feet wide by 7-feet tall powder, oven, and blasting booths, plus full-service powder coating, sandblasting, and masking area. The shop is set up to allow them to expand their equipment inventory and staff as necessary.

Primarily an Industrial/Commercial Shop

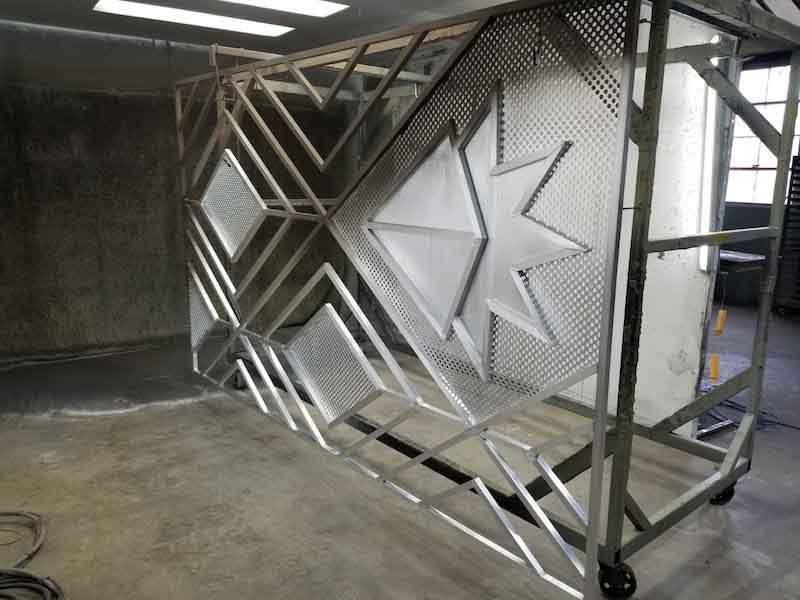

Starting off, Old North Powder Coat is primarily an industrial/commercial shop, with some walk-in consumer/residential traffic. Alex says the largest single piece they have worked on so far was a 20x8x6 steel bus stop canopy for the Greater Dayton Regional Transit Authority.

Starting off, Old North Powder Coat is primarily an industrial/commercial shop, with some walk-in consumer/residential traffic. Alex says the largest single piece they have worked on so far was a 20x8x6 steel bus stop canopy for the Greater Dayton Regional Transit Authority.

“We are the powder coater of choice for a company who manufactures the highest quality satellite dishes for luxury watercraft,” he says. “We also powder coat many high volume metal pieces of all sizes that require blasting and masking, which we also do in the house.”

Old North has also done a number of beautifully crafted finesse gates, fences, and metal sculptures for restaurants and bars, as well as outdoor residential entertainment and recreational sets.

Both Phil and Alex were in the metal finishing industry for 11 years before getting the itch to be their own bosses. Phil was a powder coating department manager-operator, and Alex was the production manager who led a team performing aluminum anodizing, black oxide, chem film, electropolish, hard coat anodizing, and passivation.

Ramping Up Quickly as Required

Currently, the brothers are handling their current workload with some part-time help as they need it. But they have both managed metal finishing crews over two and three shifts, so they say they are perfectly capable of ramping up quickly as required.

Currently, the brothers are handling their current workload with some part-time help as they need it. But they have both managed metal finishing crews over two and three shifts, so they say they are perfectly capable of ramping up quickly as required.

“We see that coming soon,” Phil says. “We pride ourselves on delivering for our customers and doing whatever needs to be done to meet their schedules.”

Old North Powder Coat being such a young company, the Ohls brothers are focusing their time and energy on working with what they have, building and maintaining their customer base, and doing high volume and the highest quality work possible.

“Once we feel we’re doing right by our customer base, we will be open to other services,” Alex says. “We’re intrigued with hydrocoating, laser/jet cutting of metals, and possibly fabricating some of our own tagging and decal products for retail.”

Phil suggests that perhaps they may also be able to help some customers by offering small welding fixes on-site or jobbing out the larger ones, as requested.

“We’ll see how things develop over the next several years,” he says.

Feedback and Referrals

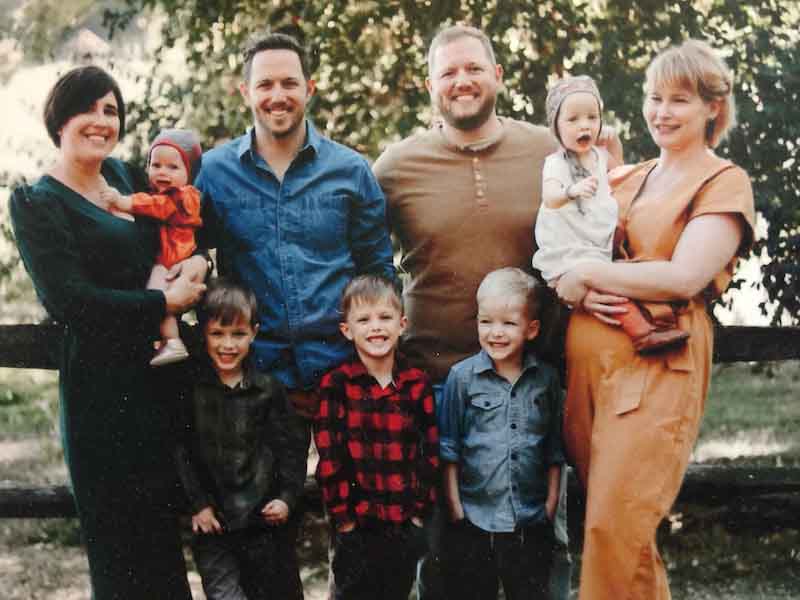

Alex and Phil with their dad, Jeff, and stepmom, Colleen, along with their Alex and Phil's children.For now, the Ohls are doing everything they can for their existing customers to meet timing, quality, and pricing requirements and are getting great feedback on the quality of their workmanship, which is a great source of pride for the team. They are also getting referrals, which they say is the greatest vote of confidence. In addition, both Phil and Alex are constantly expanding their local and regional metal finishing network through calls, emails, and social media.

Alex and Phil with their dad, Jeff, and stepmom, Colleen, along with their Alex and Phil's children.For now, the Ohls are doing everything they can for their existing customers to meet timing, quality, and pricing requirements and are getting great feedback on the quality of their workmanship, which is a great source of pride for the team. They are also getting referrals, which they say is the greatest vote of confidence. In addition, both Phil and Alex are constantly expanding their local and regional metal finishing network through calls, emails, and social media.

“We also do email blasts and traditional direct mailings,” Phil says.

Old North Powder Coat inherited some fairly new equipment when they purchased the former powder coating operation, including a Gema coating system and ovens made by RTT Engineered Solutions, which was formerly Col-Met.

“The Gema guns are a very nice piece of equipment, and I love all the digital features,” says Phil. “You can see it on our cells, and you can even program it for certain jobs. I don’t do that, but I hear it’s a good feature for those who use it.”

Partnering with Various Suppliers

The company has partnered with several other suppliers that have been instrumental in their initial success. They say Tiger Drylac makes exceptional powder coat products, has good customer service, and also ships pretty quickly. Alex says that IFS Coatings makes a good product, has good customer service, is reasonably priced, and ships quickly.

The company has partnered with several other suppliers that have been instrumental in their initial success. They say Tiger Drylac makes exceptional powder coat products, has good customer service, and also ships pretty quickly. Alex says that IFS Coatings makes a good product, has good customer service, is reasonably priced, and ships quickly.

“Cardinal Paint and powder are similar to IFS,” he says. “Ditto with Sherwin Williams and Axalta. Prismatic Powders is the go-to for any special effect or smaller quantity items and has a great quality as well.”

Both Alex and Phil say they are seeing more customers come to them because no one else is able to get them the quality they need. The win-win is that Old North Powder Coat saves the customer from having to keep shopping or possibly losing their contract with their customer.

“It’s good for both of us on all levels, and the bonus is the confidence we get from being able to provide that for them,” Alex says. “It tells us we are on the right track and helps us realize our quality standards, giving us the confidence to go after other similar work.”

Surpassing Customer Requirements

They have a customer who — over the past couple of years — has worked with powder coaters all over southern Ohio in search of one who can meet their very high-quality standards for some very high-end clients. When they started Old North last year, the customer heard by word-of-mouth that there were some new guys in the business, so they gave Phil and Alex a test job.

They have a customer who — over the past couple of years — has worked with powder coaters all over southern Ohio in search of one who can meet their very high-quality standards for some very high-end clients. When they started Old North last year, the customer heard by word-of-mouth that there were some new guys in the business, so they gave Phil and Alex a test job.

“We did it, and it surpassed their requirements,” Phil says. “Then they gave us two more, and both of those passed inspection with flying colors. We now do work for them regularly. Successful experiences like this make it fun and rewarding to come into our own business every day.”

The company is located in Old North Dayton, a historic neighborhood northeast of downtown Dayton with a unique ethnic flavor settled by German immigrants around the turn of the 20th century. Both Alex and Phil were born and raised in Kettering, a suburb just south of Dayton, and they have always been aware of the history of Old North Dayton.

“Given our German heritage, we are very proud of our location and its significance to the settling of Dayton, and so we named our company in its honor,” Alex says.

Colleen Ohl, the majority owner, is a graduate of the University of Virginia Darden School of Business and has held a number of corporate leadership positions. She currently is the operational excellence lead for a national consulting firm. Her husband, Jeff, has been a graphic design entrepreneur for many years.

Serving as Owner-Operators

The Ohl brothers realize they are in a family business, and although they are not direct owners yet, they feel like it when they perform all the production, purchasing, customer service, estimating, and billing.

The Ohl brothers realize they are in a family business, and although they are not direct owners yet, they feel like it when they perform all the production, purchasing, customer service, estimating, and billing.

They are both buying into the business in order to own it outright in the next several years and look at themselves as owner-operators, with full control over the business and day-to-day decisions. For now, they are appreciative of the opportunity their dad and step-mom gave them with the financial help and guidance, as well as that of their mother, Carole, who comes from a family of entrepreneurs and has started a couple of businesses herself.

“They keep us on our toes and have fully embraced our vision and dedication to this business,” Phil says. “But most importantly, we’re both family men with incredibly supportive wives and five kids between us, all under seven years old. So, having our own business runs in our blood, and we’re putting everything we’ve got into Old North Powder Coat Co.”